Cooling fin and cascaded caulking groove radiator

A heat dissipation fin and heat sink technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the small contact area between the base and the phase change chamber, and reduce the heat dissipation effect of the phase change chamber , large contact thermal resistance, etc., to achieve the effect of convenient installation and operation, easy processing and manufacturing, and small transfer thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

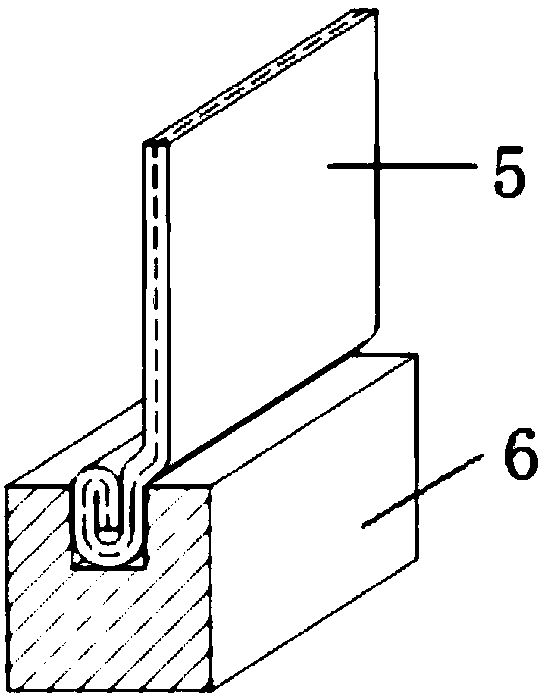

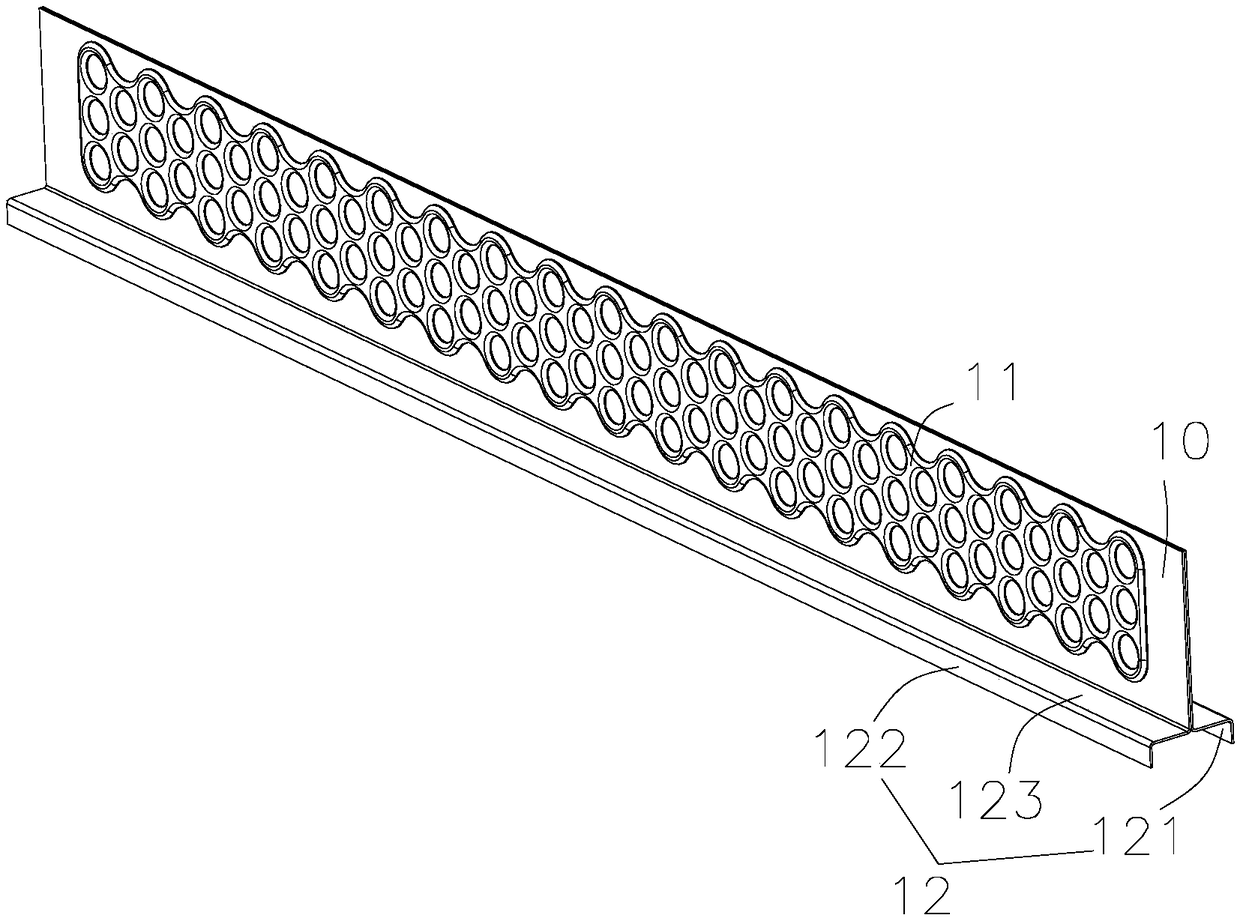

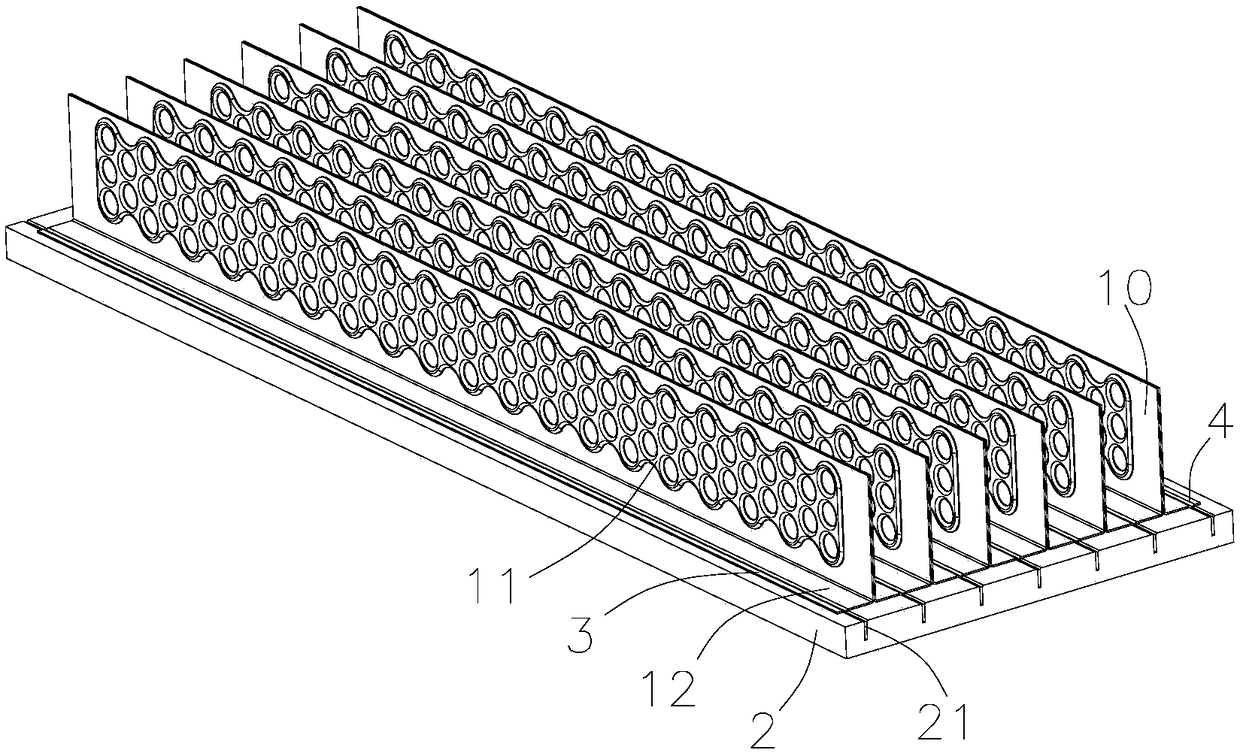

[0037] Such as Figure 2~4 As shown, a heat dissipation fin includes a fin body 10 and a bent portion 12, one side of the fin body 10 has the bent portion 12, and the cross section of the bent portion 12 is n-shaped, The bending part 12 includes a first bending section 121, a second bending section 122 and a connecting section 123 connecting the first bending section 121 and the second bending section 122, the first bending section 121 and the second bending section 121 The two bending sections 122 are separated from each other, and the first bending section 121 and the second bending section 122 are parallel to each other. Specifically, the fins are compositely formed by two substrates, and it is in a plate structure, and a closed hollow cavity 11 is arranged between the two substrates, and the hollow cavity 11 is filled with a phase change working fluid. And in a negative pressure state, this kind of fin is also called a flat heat pipe, which conducts heat through the phase...

Embodiment 2

[0050] In this embodiment, the difference between a cascaded slot radiator and Embodiment 1 is that the width of the first installation groove 21 among the several installation grooves 21 is the same as the thickness of the first bent section 121. matching, the width of the last mounting groove 21 matches the thickness of the second bent section 122; the first bent section 121 of the first fin in the plurality of fins is interference inserted into the second In one of the installation grooves 21 , the second bent section 122 of the last fin is interference inserted into the last installation groove 21 , and the first slotting piece 3 and the second slotting piece 4 are not needed.

Embodiment 3

[0052] Such as Figure 5-7 As shown, in this embodiment, the difference between a heat dissipation fin and Embodiment 1 is that the first bending section 121 and the second bending section 122 are located on the same side of the fin body 10, and the first The bending section 121 is arranged close to the fin body 10, and the first bending section 121 and the second bending section 122 are formed by bending two substrates to one side of the fin body 10 at the same time. Separate the sides of the two substrates. For flat plate heat pipe fins filled with phase-change working fluid, it is difficult to realize the processing technology of bending two substrates to form separate bending parts 12, but in this embodiment, the sides of the fins are directly bent, which is convenient for processing and manufacturing, and Wide range of applications.

[0053] Such as Image 6 with 7 As shown, in this embodiment, the difference between a cascaded slot radiator and Embodiment 1 is that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com