Ultrasonic vacuum pump bubble removal system before measurement of gypsum slurry density

A technique for measuring the density of gypsum slurry, which is applied in the preparation of pumps, rotary piston pumps, and test samples. It can solve problems such as numerical jumps, inapplicability, and large errors, and achieve stable performance and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

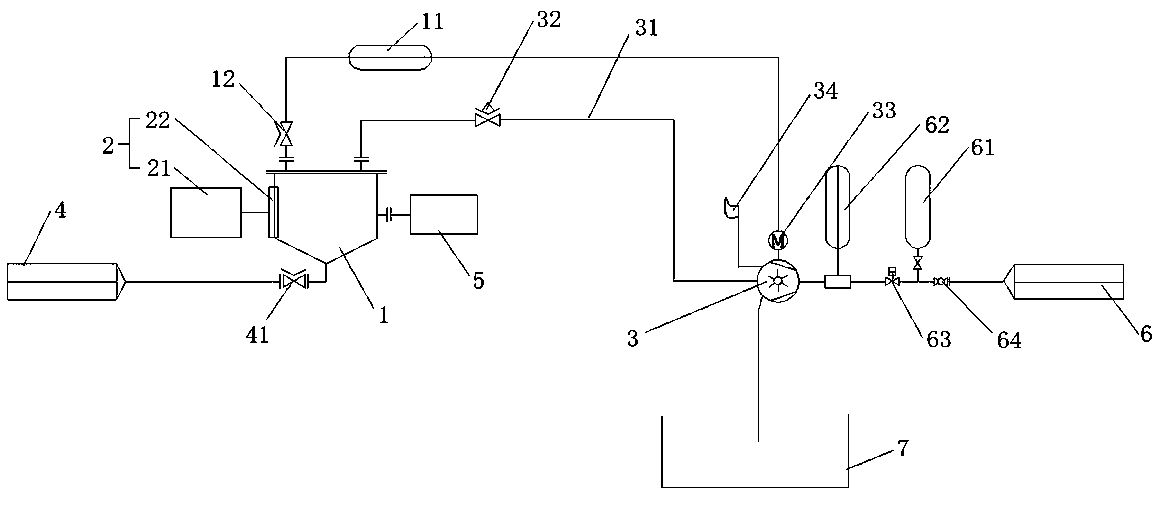

[0027] Such as figure 1 As shown, the ultrasonic vacuum pump defoaming system before the gypsum slurry density measurement includes a defoaming box 1, an ultrasonic vibration device 2 and a water ring vacuum pump 3; the defoaming box 1 is a conical bottom container, and the ultrasonic vibration device 2 is installed on On the side walls around the defoaming box 1; the bottom of the defoaming box 1 is provided with a gypsum slurry inlet, which is connected to the outlet of the absorption tower gypsum slurry system 4, and between the absorption tower gypsum slurry system 4 and the gypsum slurry inlet. The slurry supply control valve 41, the top of the defoaming box 1 is connected to the water r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com