Calibration device and calibration method for alignment of guidance radar mechanical axis and electrical axis

A calibration method and technology of mechanical axis, which are applied to measurement devices, optical devices, radio wave measurement systems, etc., can solve the problem of affecting the alignment accuracy of the mechanical axis and the electric axis, affecting the missile's ability to intercept and track the target, and the zero of the electric axis. The position and the zero position of the missile mechanical axis may not be precisely aligned, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

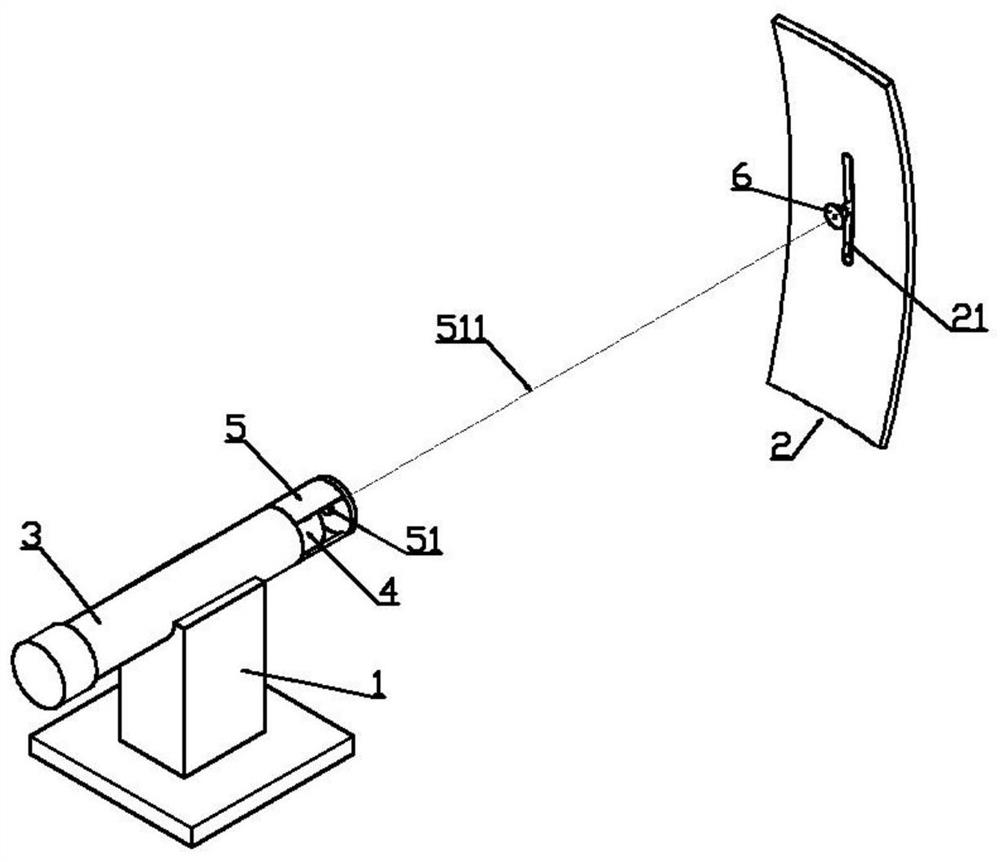

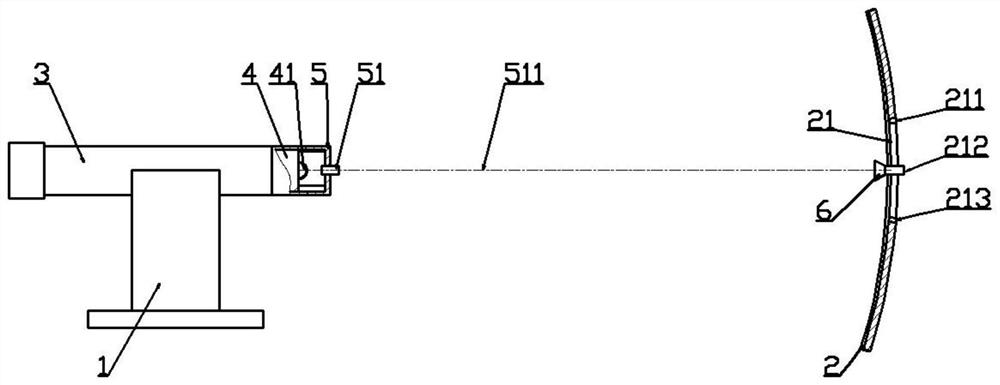

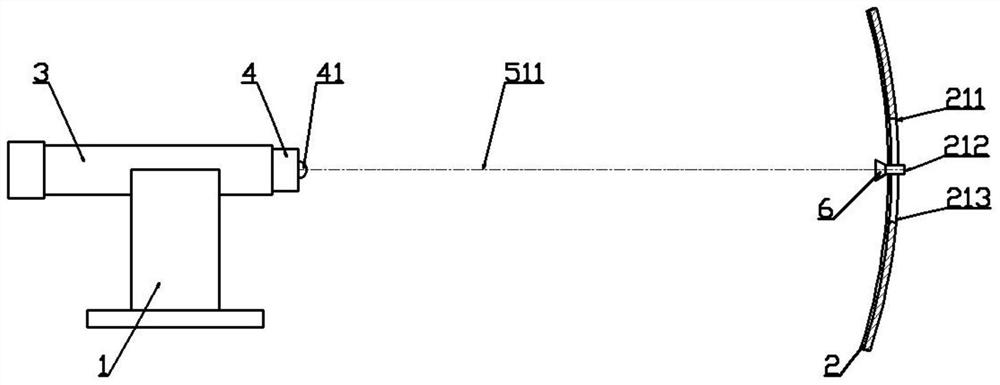

[0024] Such as Figure 1-2 As shown, a missile 3 is installed on the fixed platform 1, and a guidance radar 4 is installed in the warhead of the missile 3. With the launch head 41 of the guidance radar 4 as the center of the sphere, a calibration sphere 2 is provided in front of the guidance radar 4. The spherical surface 2 is provided with an arc-shaped groove 21 perpendicular to the ground plane. The arc-shaped groove 21 is provided with an upper groove 211 located at the upper end, a lower groove 213 located at the lower end and a zero position 212 located in the middle of the groove. The target 6 is installed in the slot 21 .

[0025] Laser alignment device 5 is also installed at the warhead of guided missile 3, and laser alignment device 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com