Device and method for cooling semiconductor devices of underground tools

A downhole tool and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as permanent damage, response reduction, device failure, etc., and achieve low cooling power consumption, lighten the burden, The effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

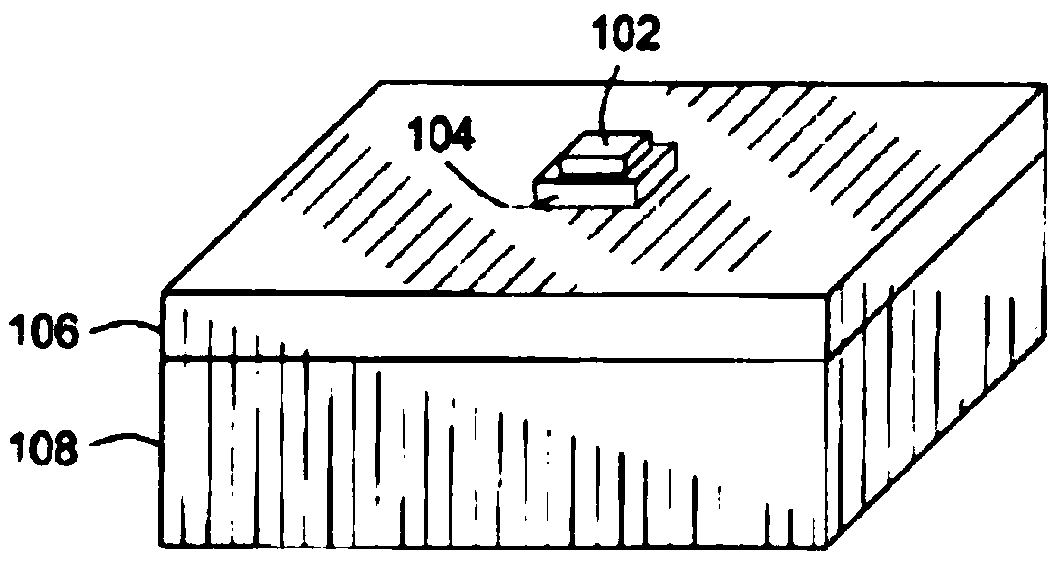

[0033] Such as figure 1 As shown, the device for cooling a semiconductor device of a downhole tool in this embodiment includes a semiconductor device 102 operable in a downhole environment. Semiconductor device 102 may be disposed on active cooling layer 104 , and active cooling layer 104 is disposed on heat sink 106 . Certainly, in order to dissipate the heat in the radiator 106 better, the radiator 106 can be arranged on the heat dissipation device 108 . In this embodiment, heat dissipation device 108 may be a high capacity thermal capacity heat sink with sufficient heat capacity to minimize the temperature rise of the die as it is cooled, thereby allowing the die to reach its lowest possible temperature to maximize the thermoelectric cooler. efficiency. For devices that require cooling to improve their performance but are not damaged by drilling temperatures, intermittent but rapid cooling to the desired temperature is possible due to the high heat pump capability of the ...

Embodiment 2

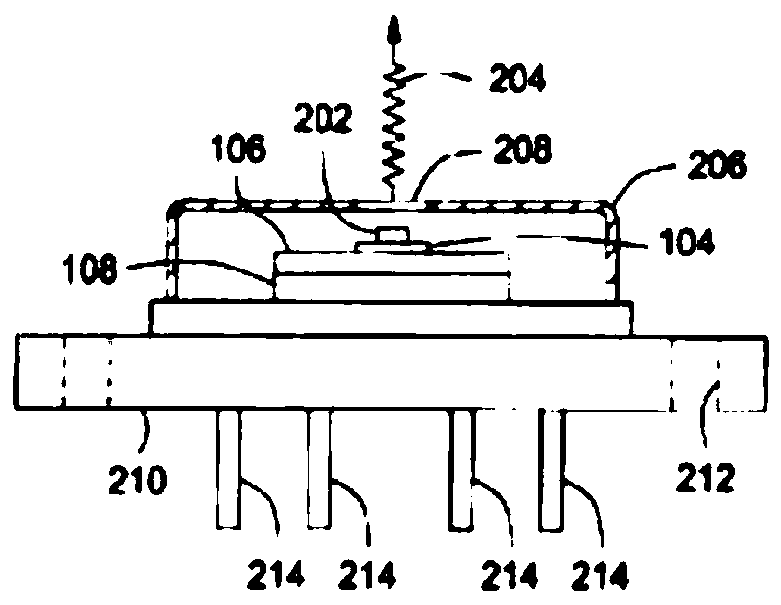

[0039] refer to figure 2 , the device for cooling a semiconductor device of a downhole tool in this embodiment includes a semiconductor device disposed on an active cooling layer 104 , and the active cooling layer 104 is disposed on a radiator 106 . Certainly, in order to dissipate the heat in the radiator 106 better, the radiator 106 can be arranged on the heat dissipation device 108 . Wherein the semiconductor device in this embodiment is the electromagnetic energy source 202 , the device for cooling the semiconductor device of the downhole tool in this embodiment can be packaged, which includes the electromagnetic energy source 202 arranged in the package 206 . The electromagnetic energy source 202 in this example is an electromagnetic energy emitter that emits electromagnetic energy 204, and the package 206 includes a window 208 that allows the electromagnetic energy emitter 204 to emit from the package 206, the package 206 can include a base 210, and the base 210 can On...

Embodiment 3

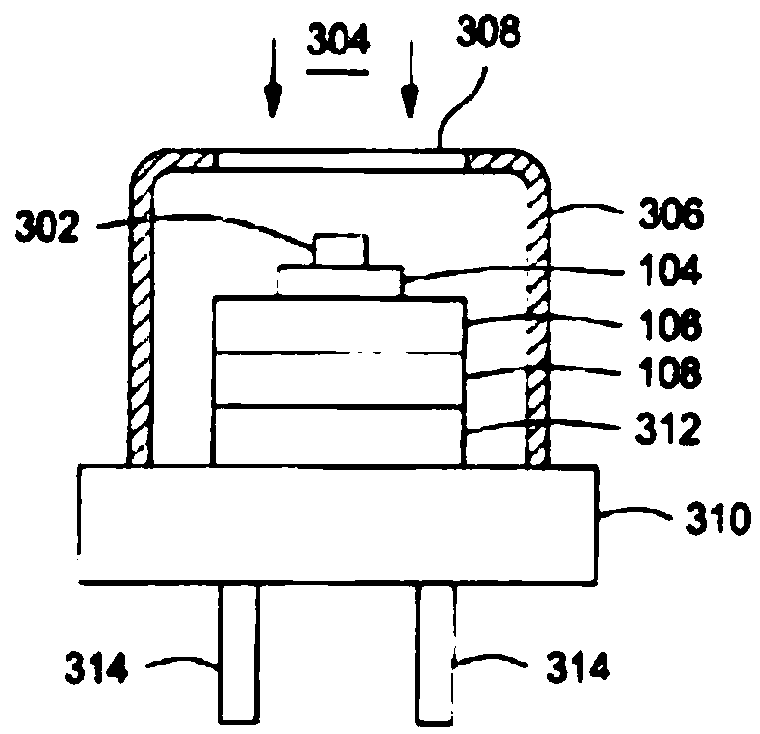

[0041] Such as image 3 As shown, the device for cooling the semiconductor device of the downhole tool in this embodiment includes the semiconductor device disposed on the active cooling layer 104 , and the active cooling layer 104 is disposed on the radiator 106 . Certainly, in order to dissipate the heat in the radiator 106 better, the radiator 106 can be arranged on the heat dissipation device 108 . The semiconductor device in this embodiment is the sensing element 302 of the detector. The sensing element 302 of the detector, the active cooling layer 104 , the heat sink 106 and the heat dissipation device 108 may then be disposed on one or more substrates 312 suitable for mounting the device within the detector package 306 .

[0042] Package 306 may also include window 308 for allowing electromagnetic energy to enter package 306 and be detected by detector 302 . The package may include a base 310 and one or more electrical leads 314 for mounting the package in a downhole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com