Rotatable spray gun and hot melt glue spray gun

A technology of rotating spray gun and hot melt adhesive, which is applied to spray devices, liquid spray devices, spray devices with movable outlets, etc. problem, to achieve the effect of compact structure, stable temperature and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

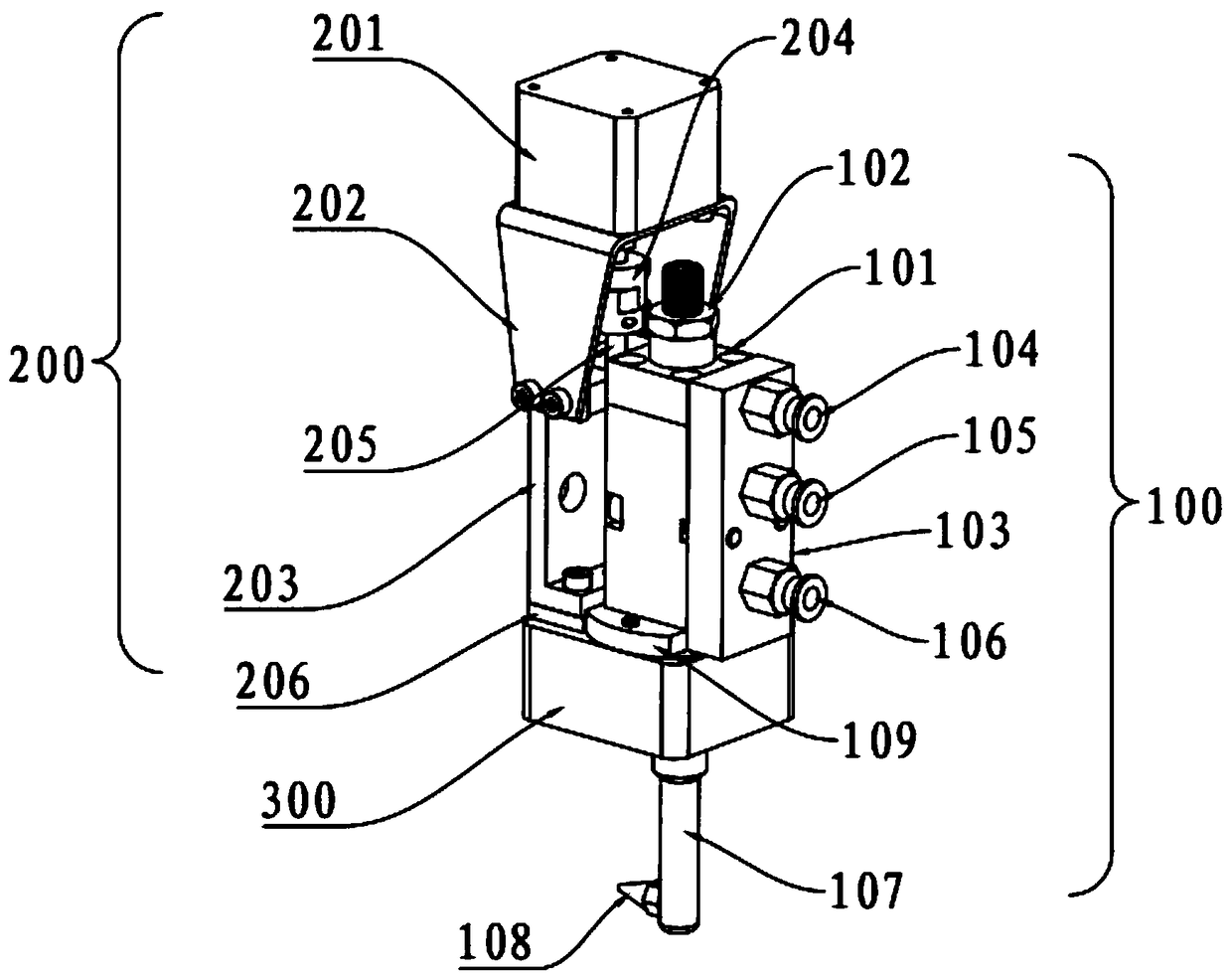

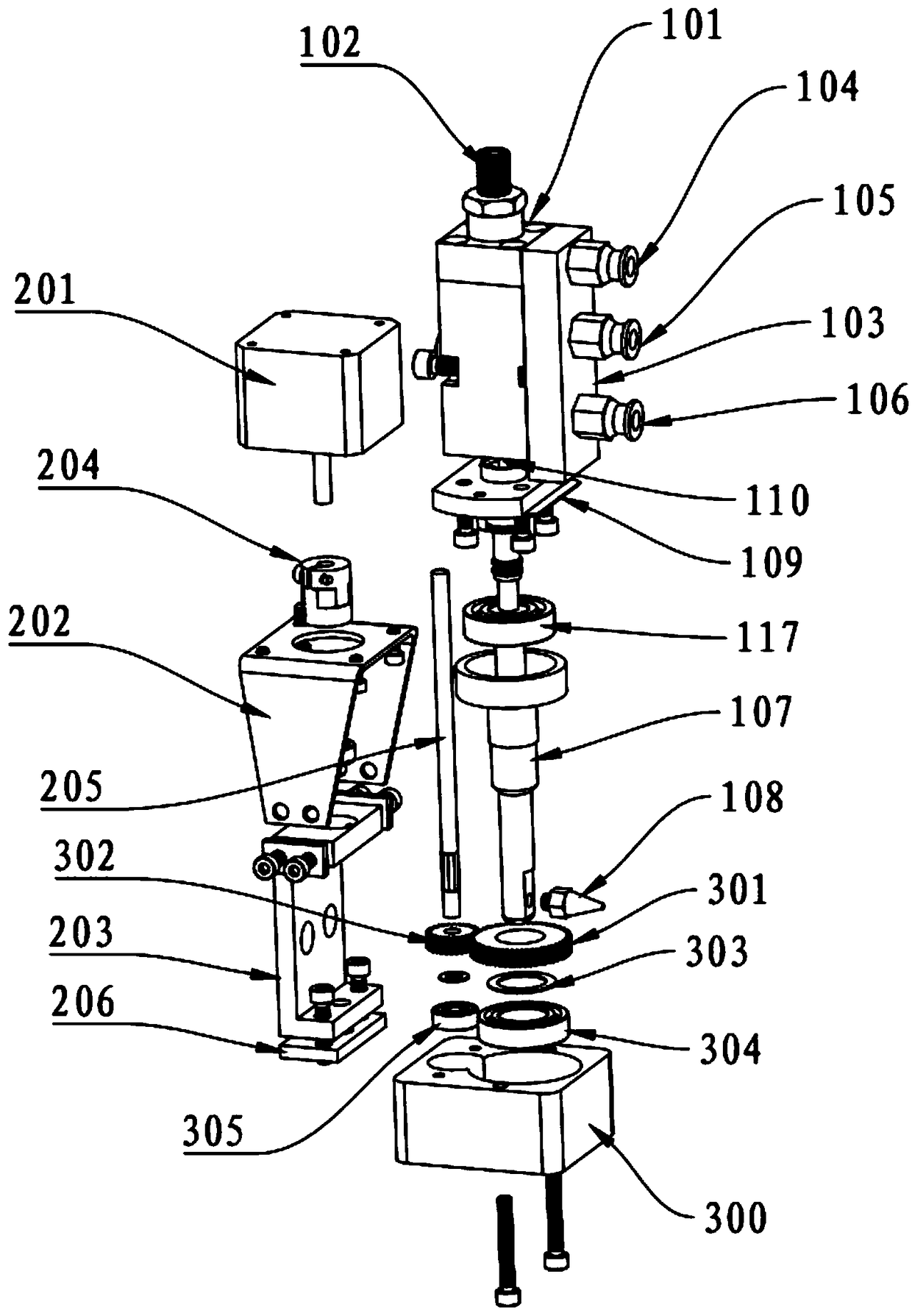

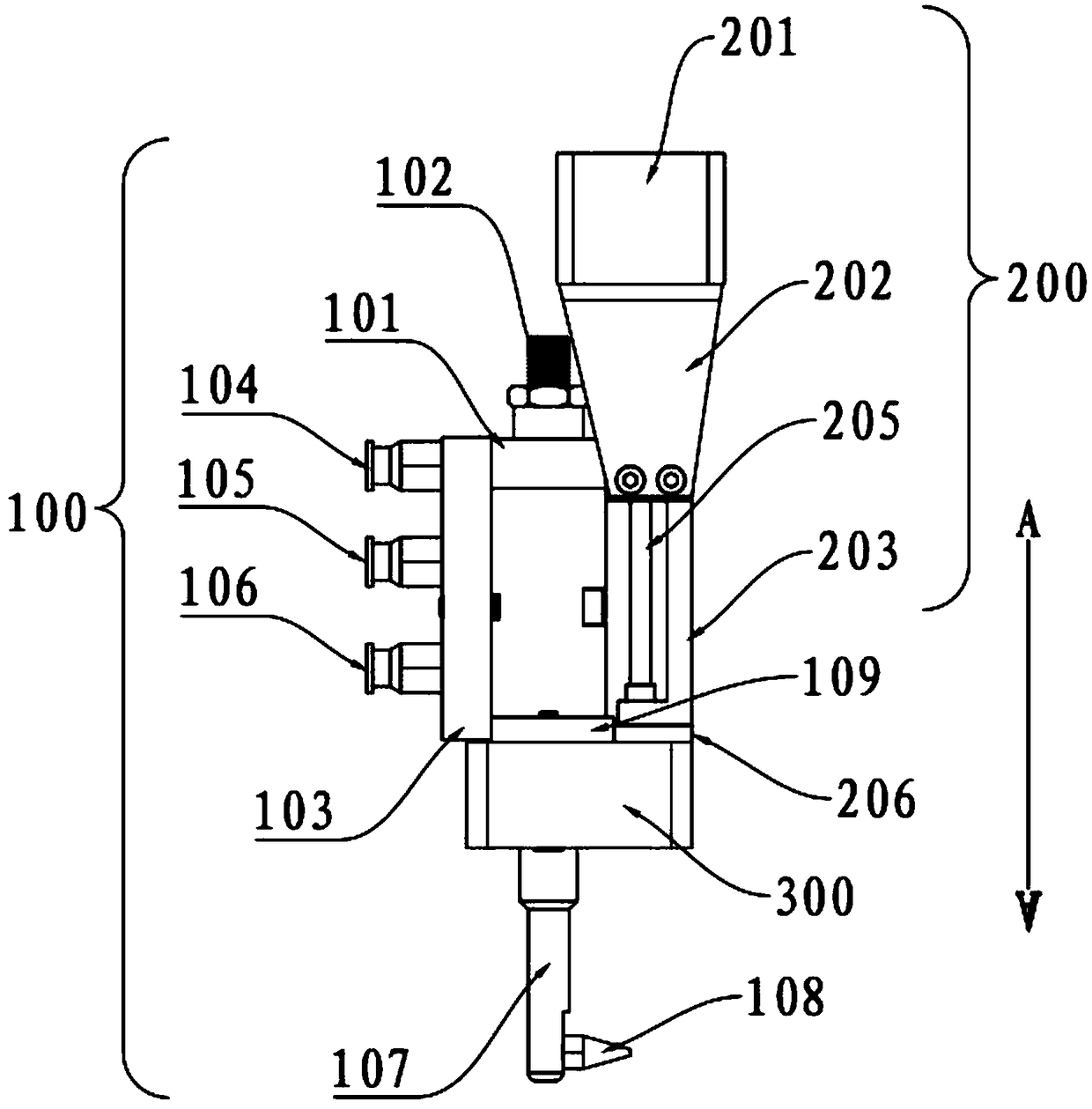

[0040] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a rotatable spray gun includes a mounting base 300, a glue spraying device 100 and a driving device 200 that drives the glue spraying device 100 to rotate;

[0041] The glue spraying device 100 includes a spray gun body 101 with a liquid glue accommodation chamber inside, and the spray gun body 101 is fixed on the mounting seat 300 via a base 109;

[0042] One side of the spray gun body 101 is provided with a first air inlet 115, a second air inlet 116 and a liquid inlet 111 communicating with the accommodating chamber;

[0043] The spray gun body 101 is provided with an adjusting screw 102, the chamber of the spray gun body 101 is provided with a piston 114 and a thimble 110, one end of the thimble 110 is fixedly connected to the piston 114, and the thimble 110 The other end is arranged on the liquid outlet of the chamber of the spray gun body 101;

[0044] An elastic body 113 is...

Embodiment 2

[0057] like Figure 7 , Figure 8 and Figure 9 As shown, a hot melt adhesive spray gun also includes a thermal insulation heating device 400 fixed on one side of the spray gun body 101. The thermal insulation heating device 400 includes a solenoid valve 402 and a heating insulation block 404. The solenoid valve 402 The air supply pipe 403 is fixed on the heating insulation block 404, the solenoid valve 402 is fixedly provided with an air supply joint 401 communicating with the air supply pipe 403, and one end of the air supply pipe 403 passes through the heating insulation block. The block 404 is correspondingly connected to the first air inlet 115 and the second air inlet 116. The heating and insulating block 404 is also provided with a liquid inlet 405 and a heating pipe installation hole 406. The heating and insulating block 404 is provided with a fluid chamber 407 communicating with the liquid inlet 405 , and the fluid chamber 407 is correspondingly connected to the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com