Silk-screen printing equipment

A technology of screen printing and equipment, applied in screen printing, screen printing machines, printing, etc., can solve problems such as labor-intensive, difficult to control precision, irregular arrangement, etc., to achieve convenient absorption, reduce labor costs, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific examples.

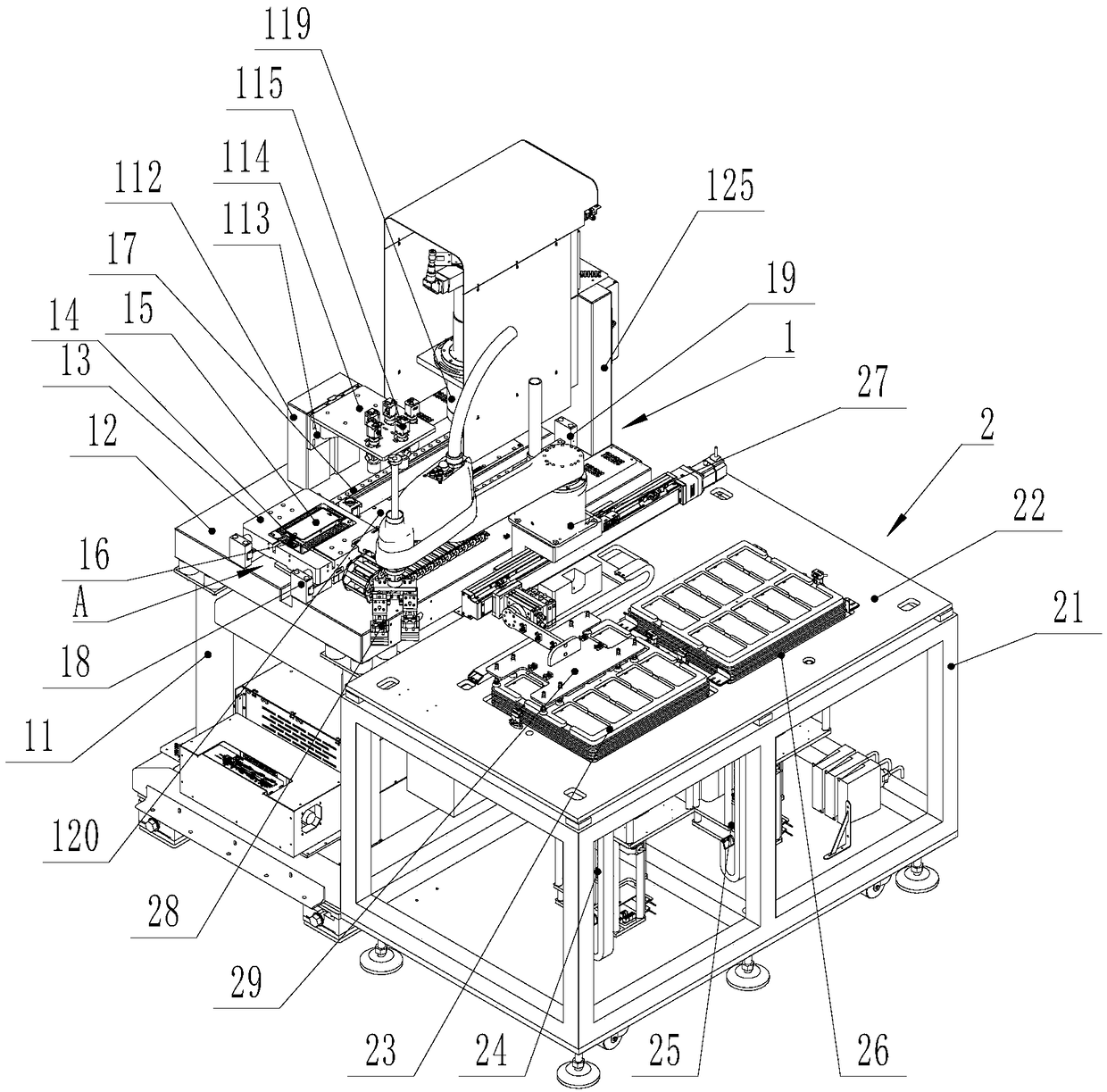

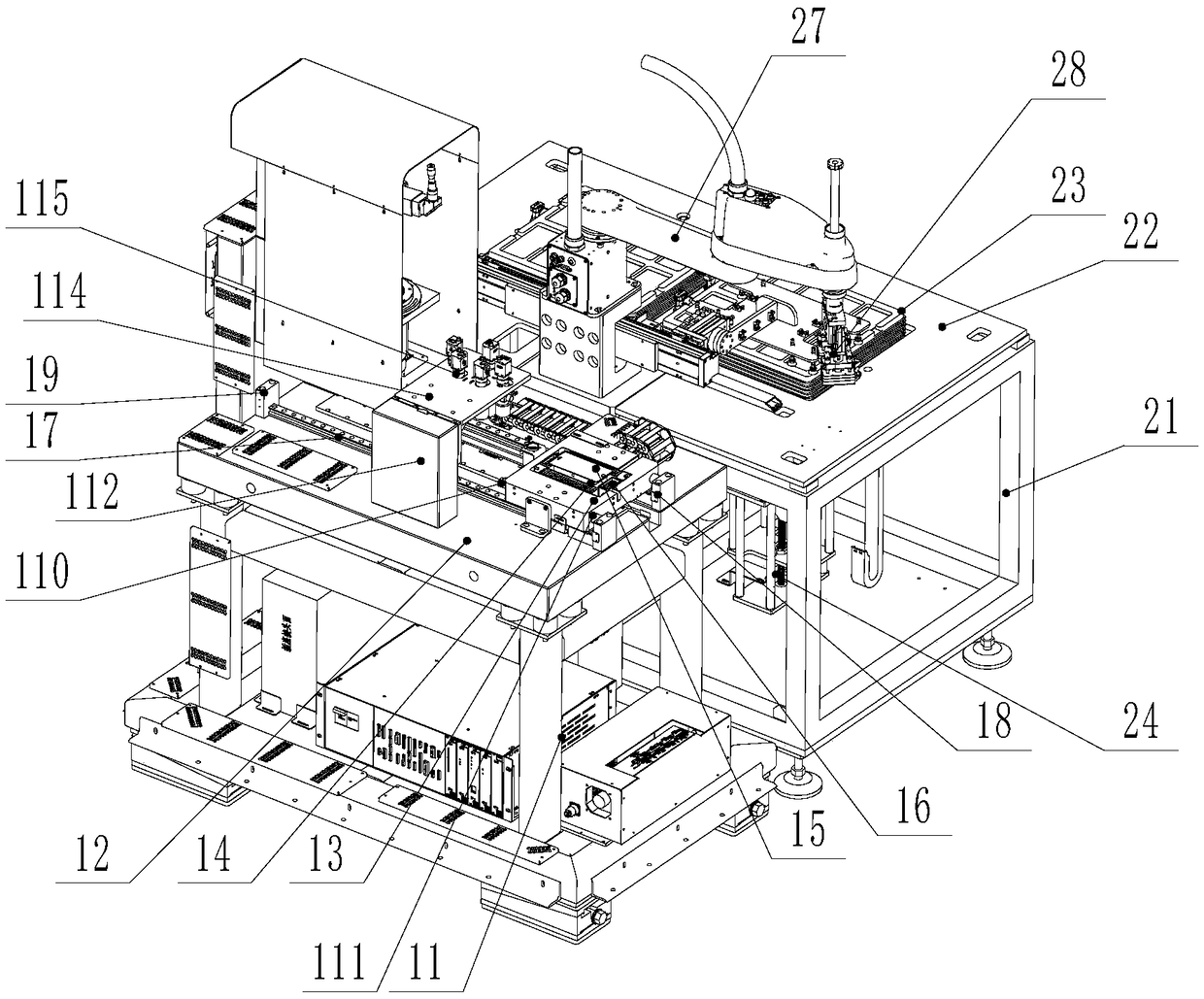

[0036] Such as figure 1 and figure 2 As shown, a screen printing equipment includes an exposure host 1 , and the screen printing equipment also includes an automatic feeding device 2 , which is arranged on one side of the exposure host 1 .

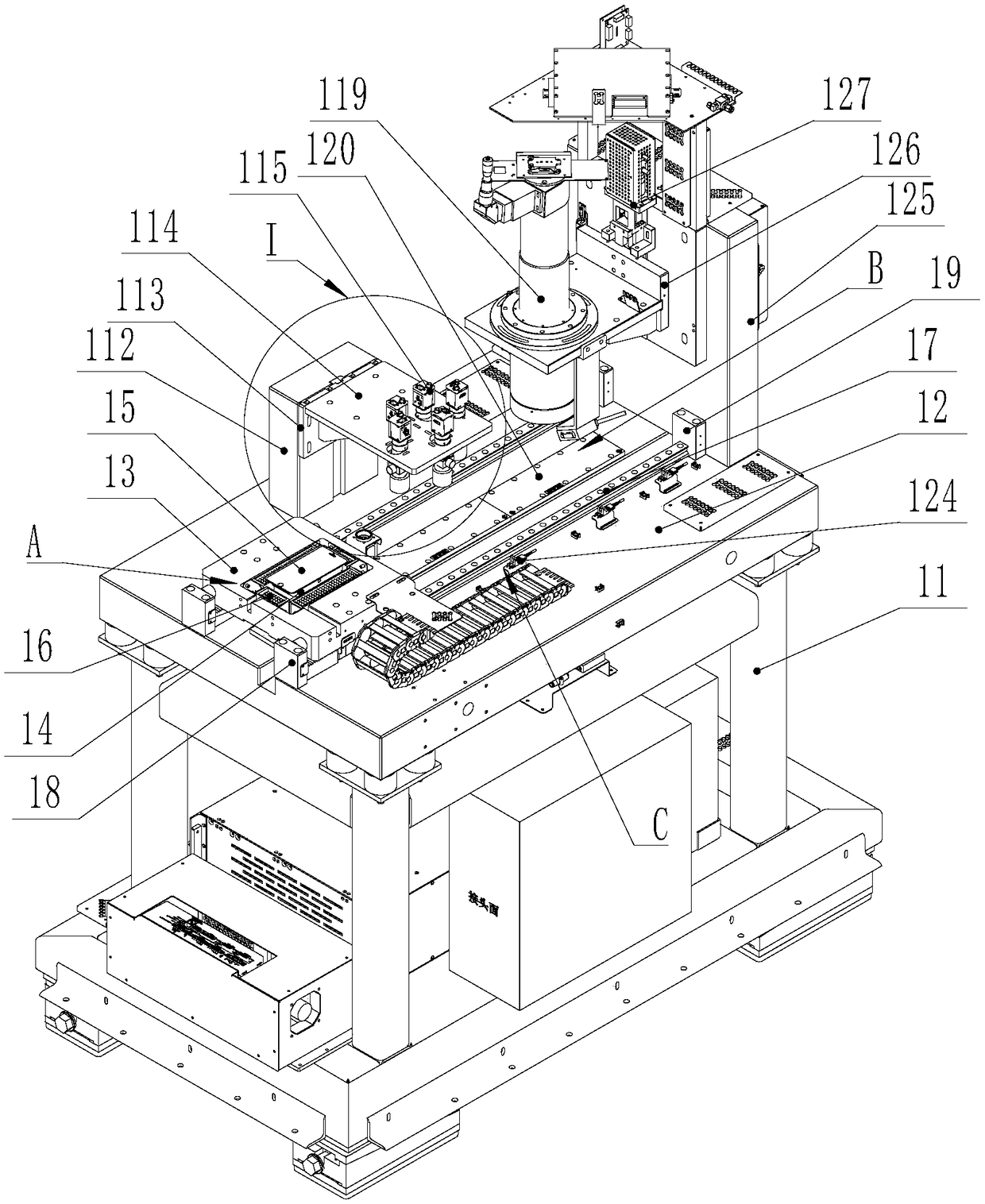

[0037] Such as Figure 3 to Figure 6 As shown, the exposure main frame 1 includes an exposure frame 11, and the exposure frame 11 is provided with a workbench 12, on which a horizontal sliding seat 13 is horizontally slidably installed, and the horizontal sliding seat 13 is driven by a horizontal power device. Drive to slide between the feeding station A and the exposure station B, the horizontal sliding seat 13 is equipped with a vacuum adsorption seat 14 for vacuum adsorption of the mobile phone case 15, the vacuum adsorption seat 14 communicates with the vacuum system, the A support seat 125 is installed on the workbench 12, and a ver...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap