A kind of emulsion and preparation method thereof

An emulsion, phase inversion technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of insufficient anti-corrosion performance, difficult deep grinding, poor corrosion resistance, etc., saving manpower and reducing pinholes , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

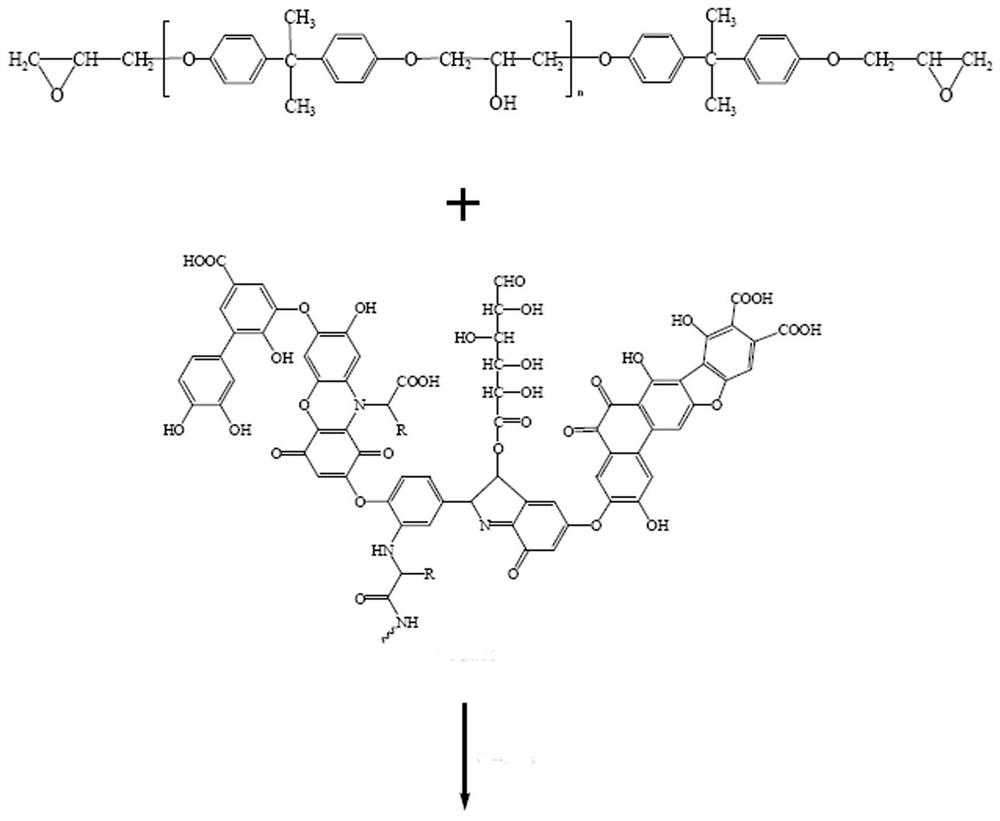

Method used

Image

Examples

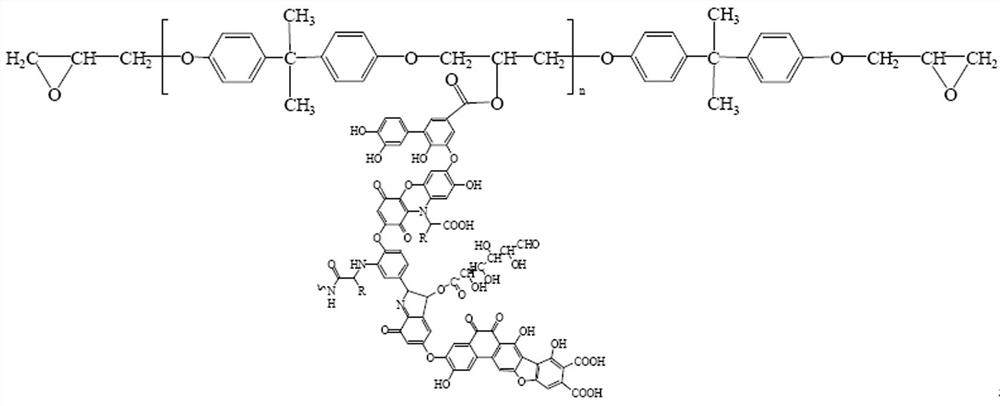

Embodiment 1

[0023] (1) Purification of humic acid: Take 30g of humic acid in a 350ml three-neck bottle equipped with a stirrer, add 200ml of absolute ethanol, heat the three-necked bottle in a water bath, start the stirrer (speed 200r / min ), until the liquid boils, take out and filter, and vacuum dry at 45°C for 12 hours to obtain the purified humic acid;

[0024] (2) Preparation of emulsion: Add 5g of water-based epoxy resin into a three-neck bottle equipped with a thermometer and a stirrer, stir for 15min (rotation speed: 200r / min), add 2g of purified humic acid, and add 3 drops of concentrated sulfuric acid As a reaction catalyst, the reaction was continued at 50°C for 3 hours, 50ml of water was slowly added, and an emulsion was obtained by phase inversion method.

Embodiment 2

[0026] (1) Purification of humic acid: Take 30g of humic acid in a 350ml three-neck bottle equipped with a stirrer, add 200ml of absolute ethanol, heat the three-necked bottle in a water bath, start the stirrer (speed 200r / min ), until the liquid boils, take out and filter, and vacuum dry at 45°C for 12 hours to obtain the purified humic acid;

[0027] (2) Preparation of emulsion: Add 5g of water-based epoxy resin into a three-neck bottle equipped with a thermometer and a stirrer, stir for 25min (rotation speed: 220r / min), add 3g of purified humic acid, and add 5 drops of concentrated sulfuric acid As a reaction catalyst, the reaction was continued at 50°C for 3 hours, 50ml of water was slowly added, and an emulsion was obtained by phase inversion method.

Embodiment 3

[0029] (1) Purification of humic acid: Take 30g of humic acid in a 350ml three-neck bottle equipped with a stirrer, add 200ml of absolute ethanol, heat the three-necked bottle in a water bath, start the stirrer (speed 200r / min ), until the liquid boils, take out and filter, and vacuum dry at 45°C for 12 hours to obtain the purified humic acid;

[0030] (2) Preparation of emulsion: Add 5g of water-based epoxy resin into a three-neck bottle equipped with a thermometer and a stirrer, stir for 20min (rotation speed: 250r / min), add 2g of purified humic acid, and add 5 drops of concentrated sulfuric acid As a reaction catalyst, the reaction was continued at 50°C for 3 hours, 50ml of water was slowly added, and an emulsion was obtained by phase inversion method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com