Meter-shaped steel structure staggered truss system and construction method thereof

A technology of steel structure frame and steel structure, which is applied in the direction of building structure and construction, can solve the problem of limited seismic performance, and achieve the effect of reasonable structure and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

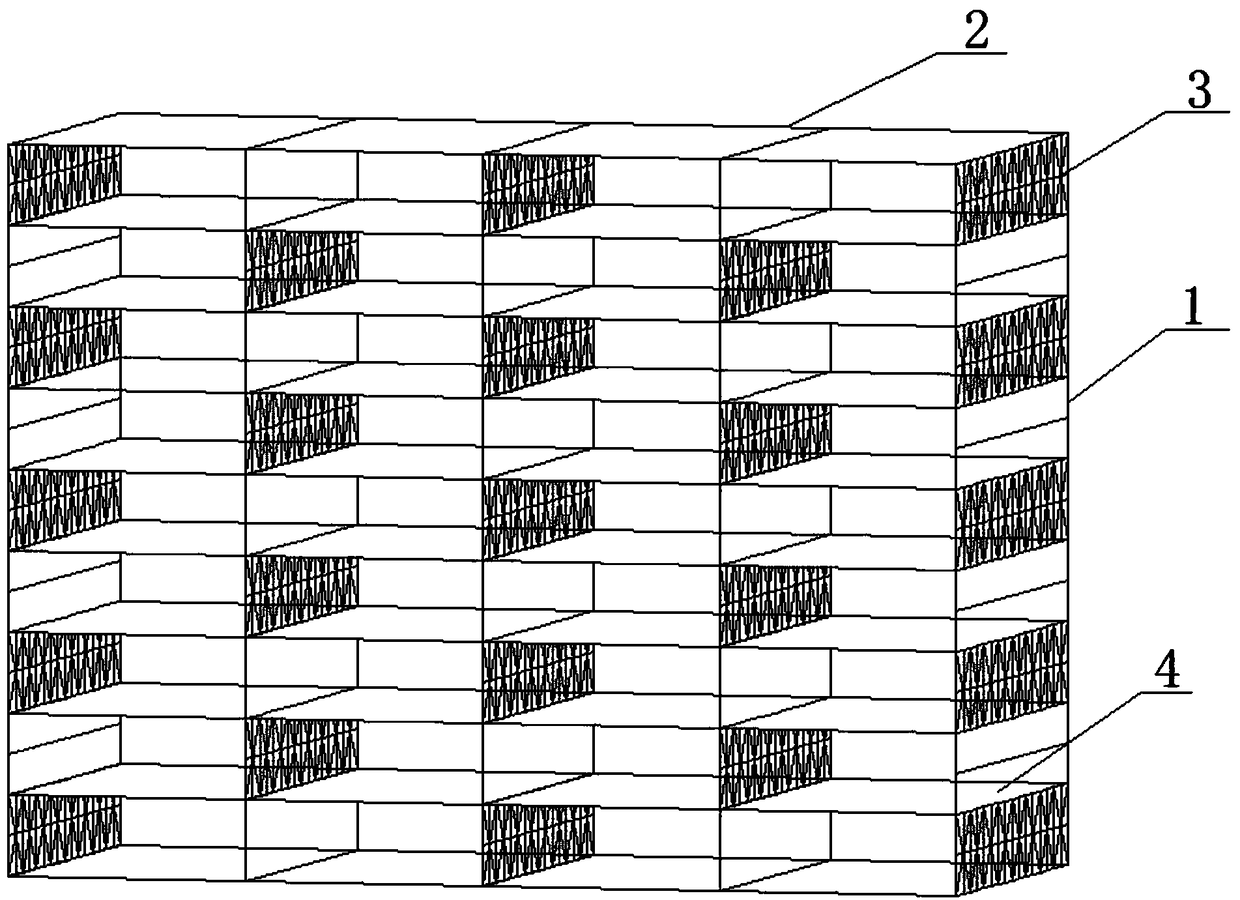

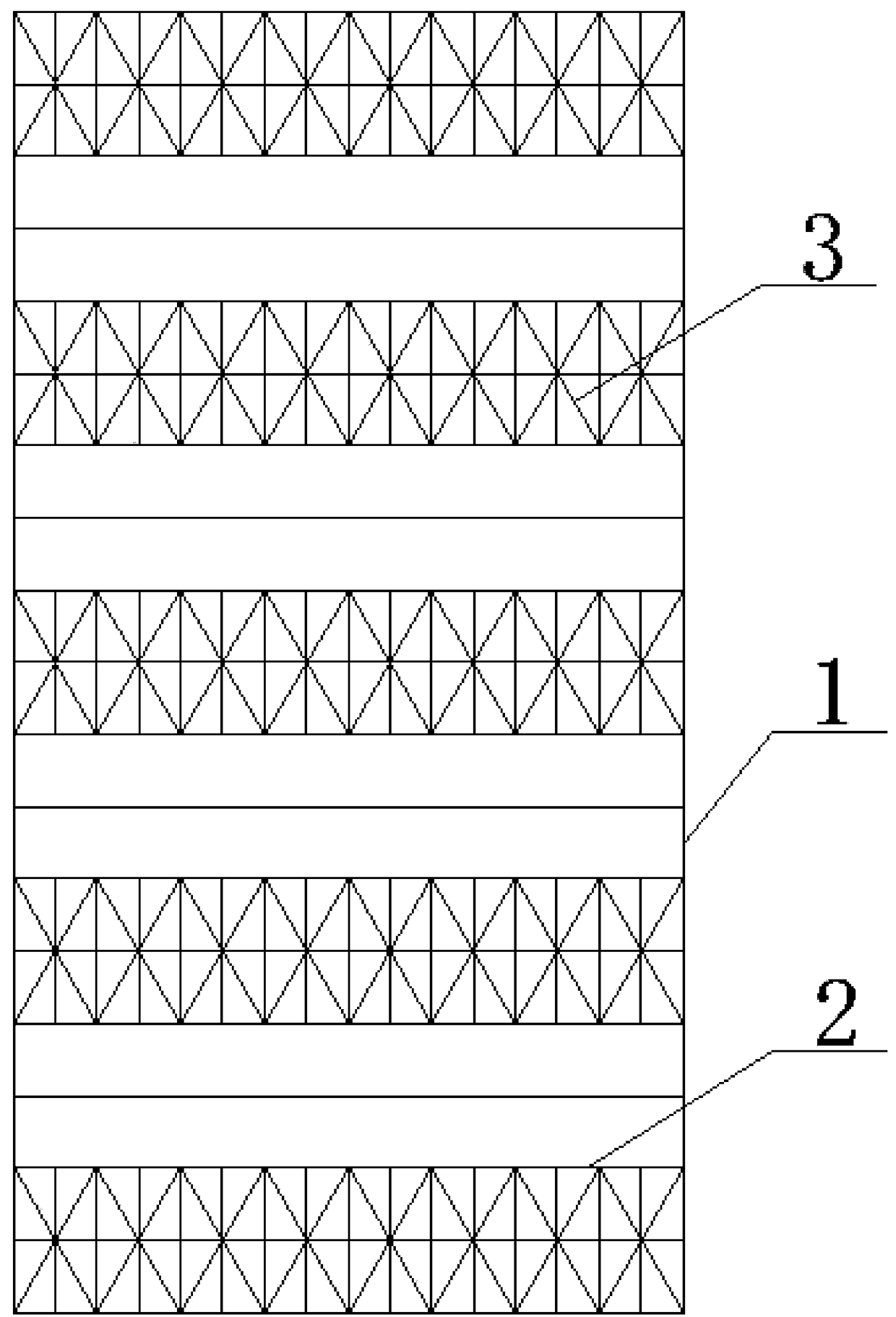

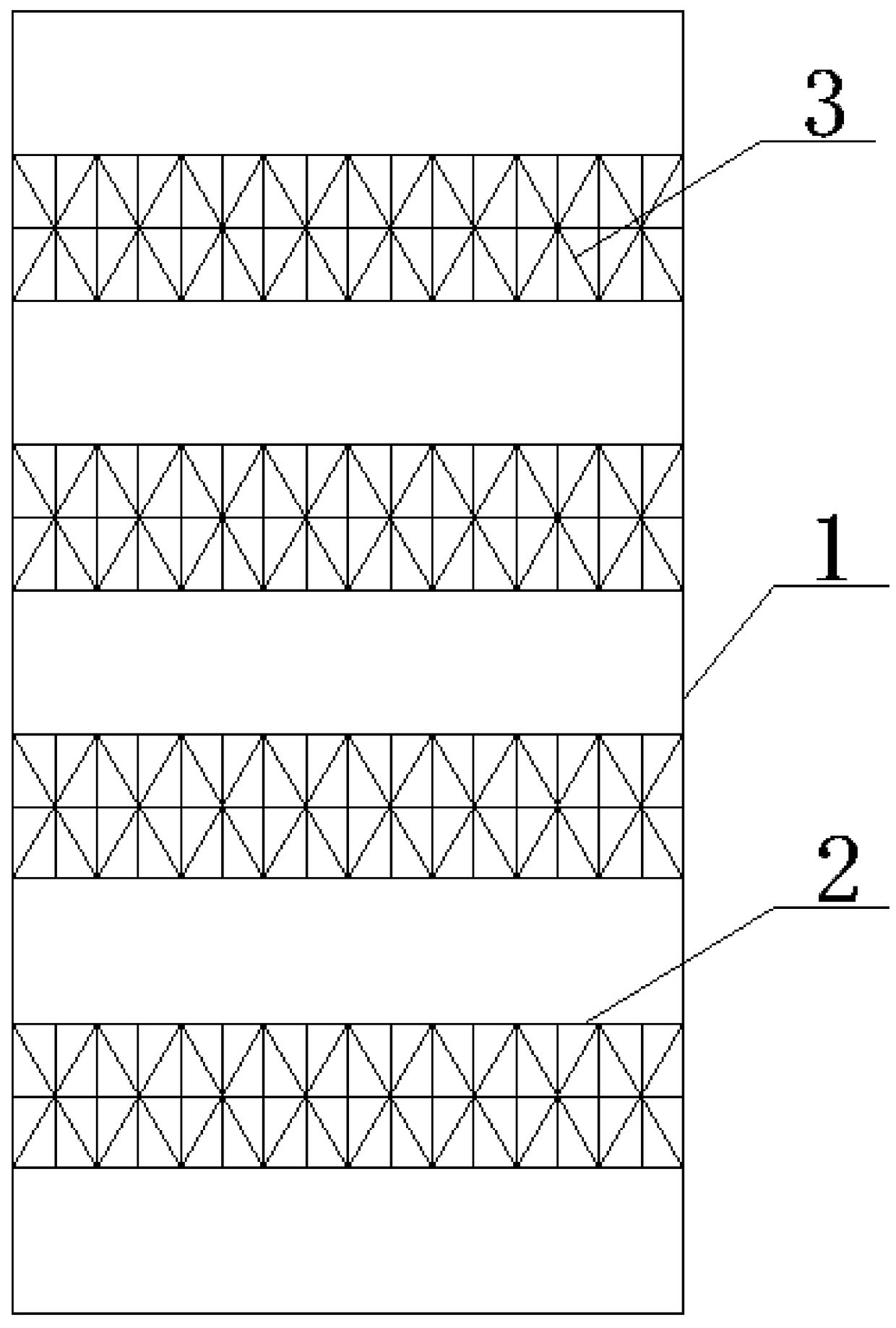

[0032] like Figure 1 ~ Figure 3 A rice-shaped steel structure staggered truss system is shown, including steel structure frame column 1, steel structure frame beam 2, steel structure truss 3 and steel truss laminated floor 4, steel structure frame column 1 is set in the steel structure staggered truss system All around, the column distance is 1 / 2 of the span distance between the steel structure trusses 3 on each floor, the steel structure frame beams 2 are riveted and welded to the rigid structure frame columns 1, and the steel structure trusses 3 are staggered in the steel structure staggered truss system , the steel structure truss 3 is connected with the rigid structure frame column 1 by riveting and welding, the steel structure truss laminated floor 4 is fixedly connected with the steel structure frame beam 2 and the steel structure truss 3, the basic unit of the steel structure truss 3 adopts a rice-shaped node truss structure, The steel structure truss 3 includes an upp...

Embodiment 2

[0035] A construction method of the staggered truss system of a rice-shaped steel structure, comprising the following implementation steps:

[0036] Step 1, according to the building and load conditions, determine the structural axis and arrange the steel structure frame columns 1, so as to determine the building span, and obtain the combined number of steel structure trusses 3;

[0037] Step 2, making the steel structure truss 3 in the factory, and fixedly connecting the rice-shaped web 7 inside the steel structure truss 3;

[0038]Step 3, riveting the steel structure frame beam 2 on the steel structure frame column 1 through bolts, and welding with the steel structure frame column 1 after the steel structure frame beam 2 is fixed;

[0039] Step 4, hoisting the steel structure truss 3 layer by layer and riveting it on the steel structure frame column 1 through bolts, and welding with the steel structure frame column 1 after the steel structure truss 3 is fixed;

[0040] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com