Novel intelligent cement clinker sintering control system

A control system and cement clinker technology, applied in the direction of furnace control device, furnace type, furnace monitoring device, etc., can solve the problems of human control, high electricity and heat consumption, large fluctuations in cement clinker output and quality, etc. Achieve the effect of reducing quantity, saving cost and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

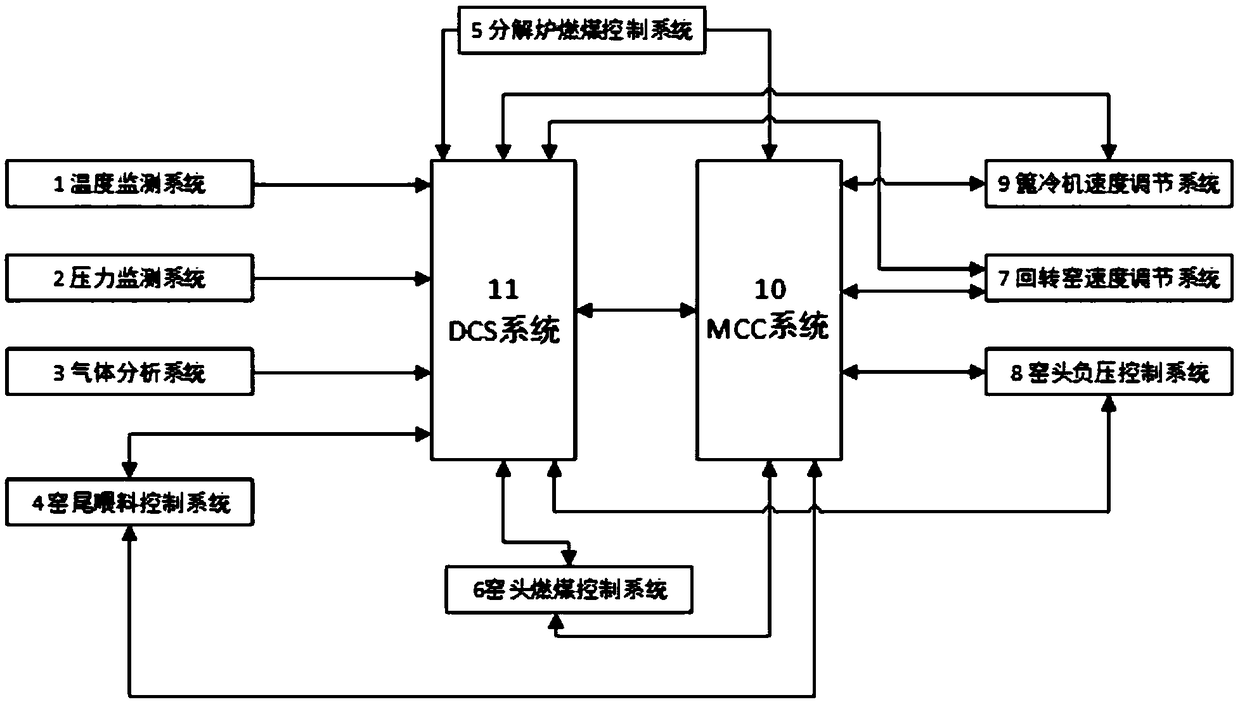

[0045] A new intelligent cement clinker firing control system, see figure 1 , including temperature monitoring system 1, pressure monitoring system 2, gas analysis system 3, kiln tail feeding control system 4, calciner coal combustion control system 5, kiln head coal combustion control system 6, rotary kiln speed adjustment system 7, kiln head Negative pressure control system 8, grate cooler speed adjustment system 9, MCC system 10 and DCS system 11;

[0046]Wherein, the MCC system 10 is connected to the DCS system 11; the temperature monitoring system 1, the pressure monitoring system 2 and the gas analysis system 3 are connected to the DCS system 11; the kiln tail feeding control system 4, the calciner coal burning control system 5. Kiln head coal combustion control system 6, rotary kiln speed adjustment system 7, kiln head negative pressure control system 8 and grate cooler speed adjustment system 9 are connected to MCC system 10 and DCS system 11 respectively.

[0047] Sp...

Embodiment 2

[0051] Embodiment 2 On the basis of Embodiment 1, the functions of temperature, pressure and gas detection are added.

[0052] temperature check. The temperature monitoring system includes a temperature detection element and a temperature transmitter; the temperature detection unit is connected to a temperature transmitter; the temperature transmitter is connected to the DCS system;

[0053] The temperature transmitter is used to transmit the temperature monitored by the temperature detection element to the DCS system; the DCS system displays the received temperature and gives an alarm when the temperature reaches a preset temperature alarm threshold.

[0054] Specifically, the temperature transmitter is used to convert the temperature signal detected by the temperature detection element into a transmissible standardized output signal. The temperature monitoring system can monitor the temperature of each link in the cement clinker burning system and upload it to the DCS syste...

Embodiment 3

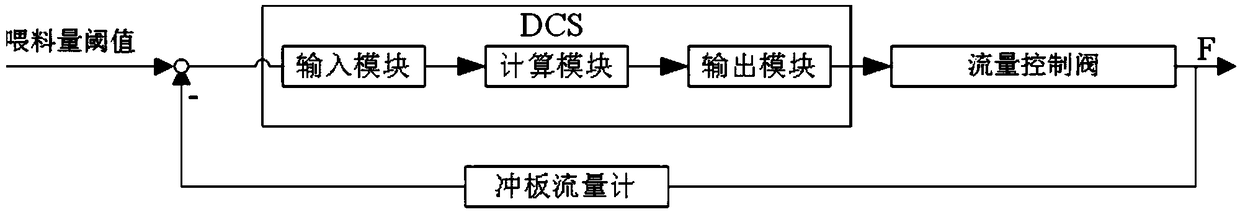

[0063] Embodiment 3 On the basis of the above embodiments, feeding control at the kiln tail is added.

[0064] see figure 2 , the kiln tail feeding control system includes a weighing feeding bin, a load sensor, a discharge flow control valve and a feeding controller; the bottom of the weighing feeding bin is provided with a discharge chute; the load sensor Installed on the weighing feeding bin, the discharge flow control valve is installed on the discharge chute of the weighing feeding bin; the load sensor and the discharging flow control valve are connected to the feeding controller; the The feeding controller is connected to the DCS system;

[0065] Specifically, the weighing feeding bin and the discharge chute are mature equipment in the existing cement clinker burning system. The material in the weighing feeding bin is discharged from the discharge chute. The unloading flow control valve is used to control the unloading speed of the weighing feeding bin. The larger th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com