A pressure testing system and method in concrete target under ultra-high-speed penetration conditions

A technology for pressure testing and concrete, applied in force/torque/work measuring instruments, measuring devices, measuring blasting force, etc. It can solve the problem of affecting the test accuracy, the inability to accurately measure the pressure distribution of the shock wave propagation law of the kinetic energy rod, and the sensor displacement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and examples.

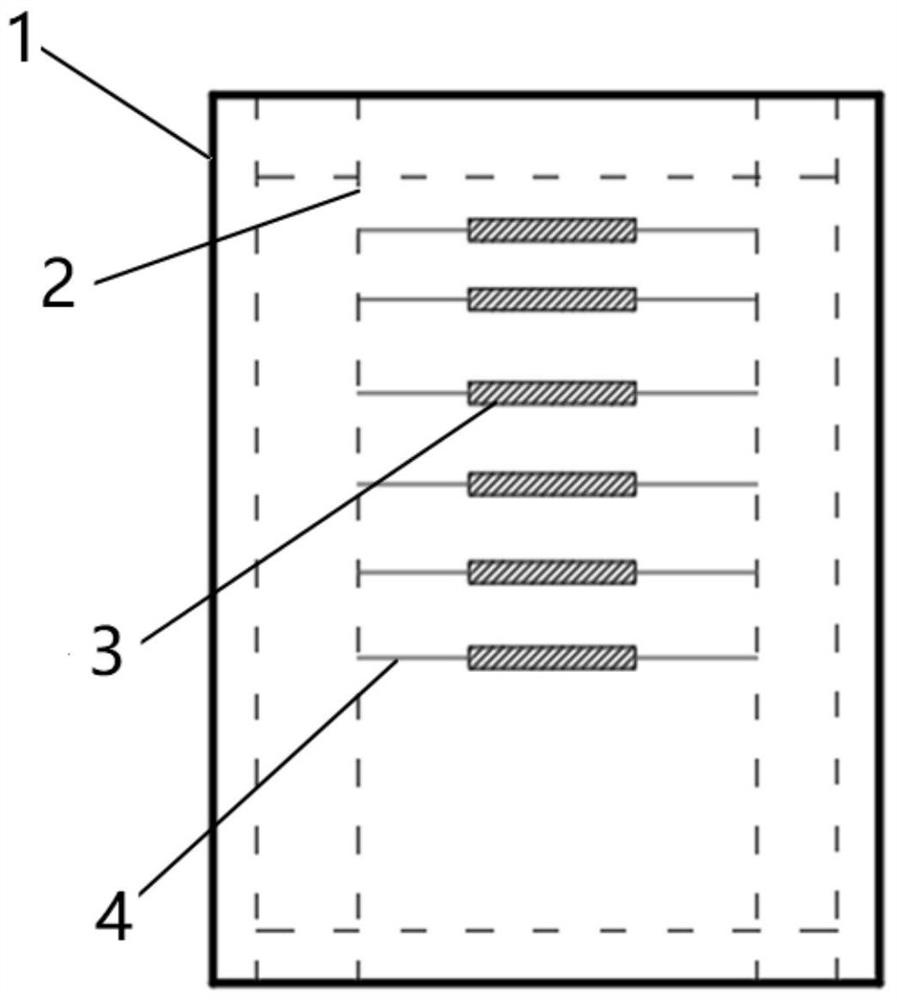

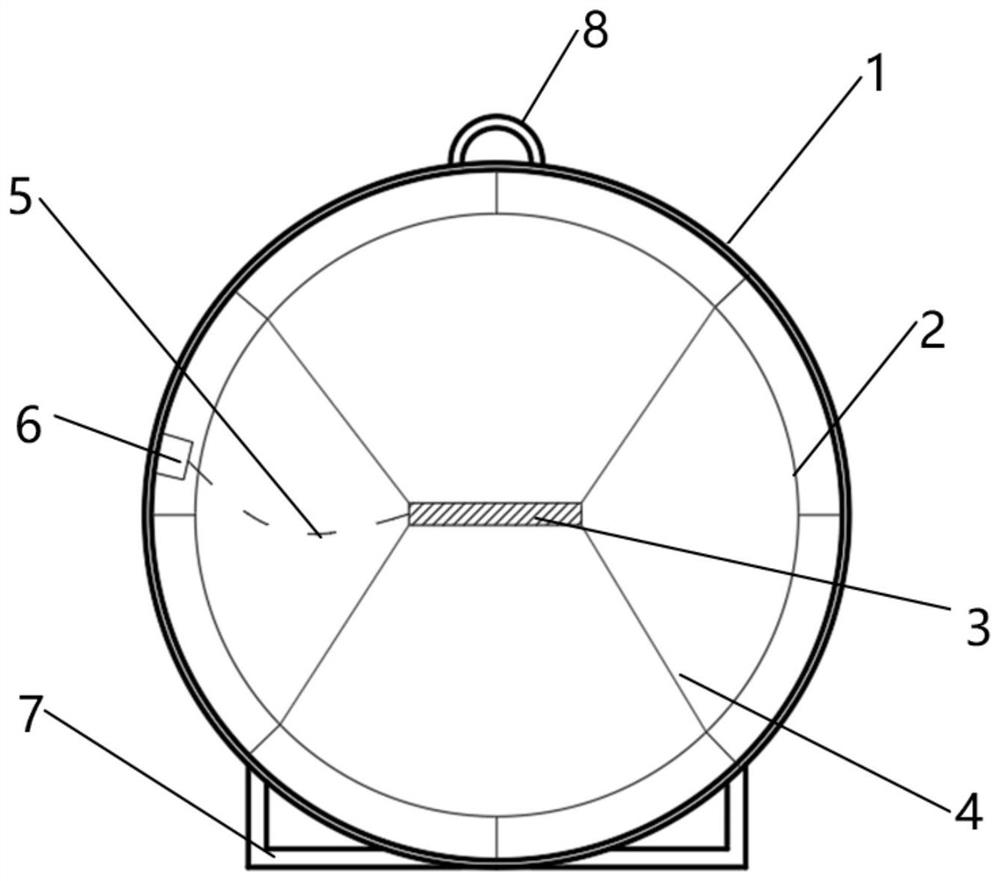

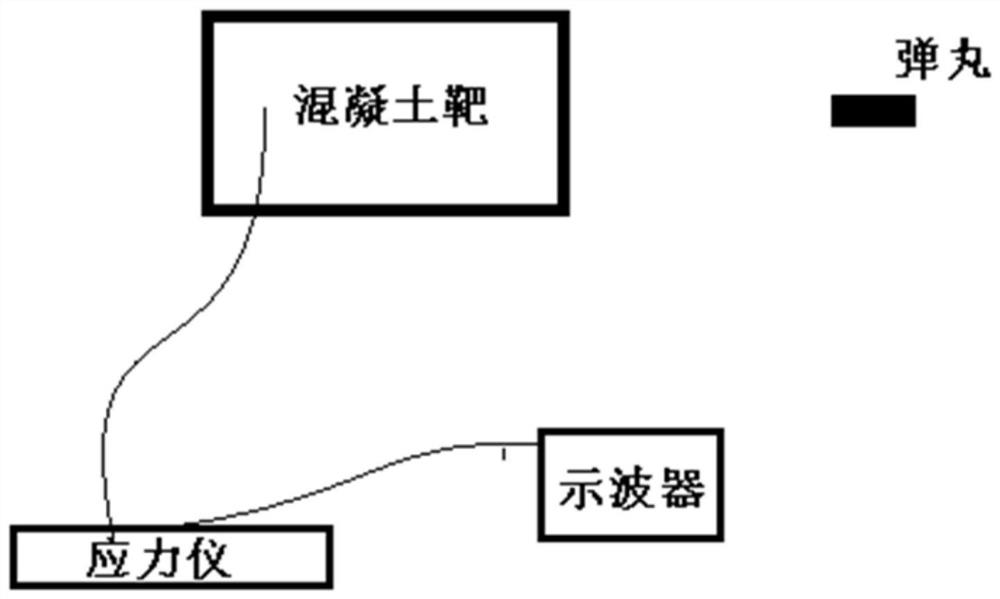

[0040] The present invention provides a concrete target pressure test system under ultra-high-speed penetration conditions, including a target hoop 1, a steel frame 2, a packaged sensor assembly 3, a rubber rope 4, concrete, a stress meter and an oscilloscope, such as figure 1 shown.

[0041] Encapsulation sensor assembly 3 comprises manganin piezoresistive sensor 11, encapsulation bottom plate 9, encapsulation cover plate 10 and coaxial cable 13, as Figure 4 , Figure 5 As shown, the sensitive element 12 of the manganin piezoresistive sensor 11 is located at the center of the package base plate 9, and the package cover plate 10 seals other parts of the manganin piezoresistive sensor 11 except the solder joint 14; the solder joint 14 of the manganese copper piezoresistive sensor 11 The coaxial cable 13 is welded, and the welding spot 14 is potted with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com