Vibration testing method for ignition device of aviation engine

A technology for aero-engines and ignition devices, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve problems such as high components, damage, and implementation of vibration test methods that are not involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

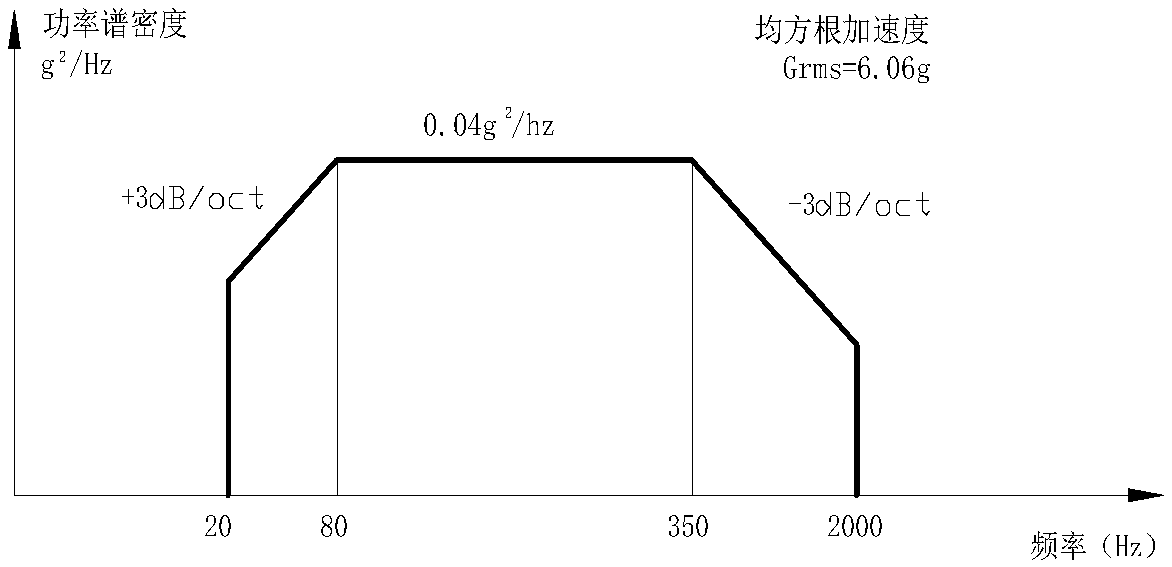

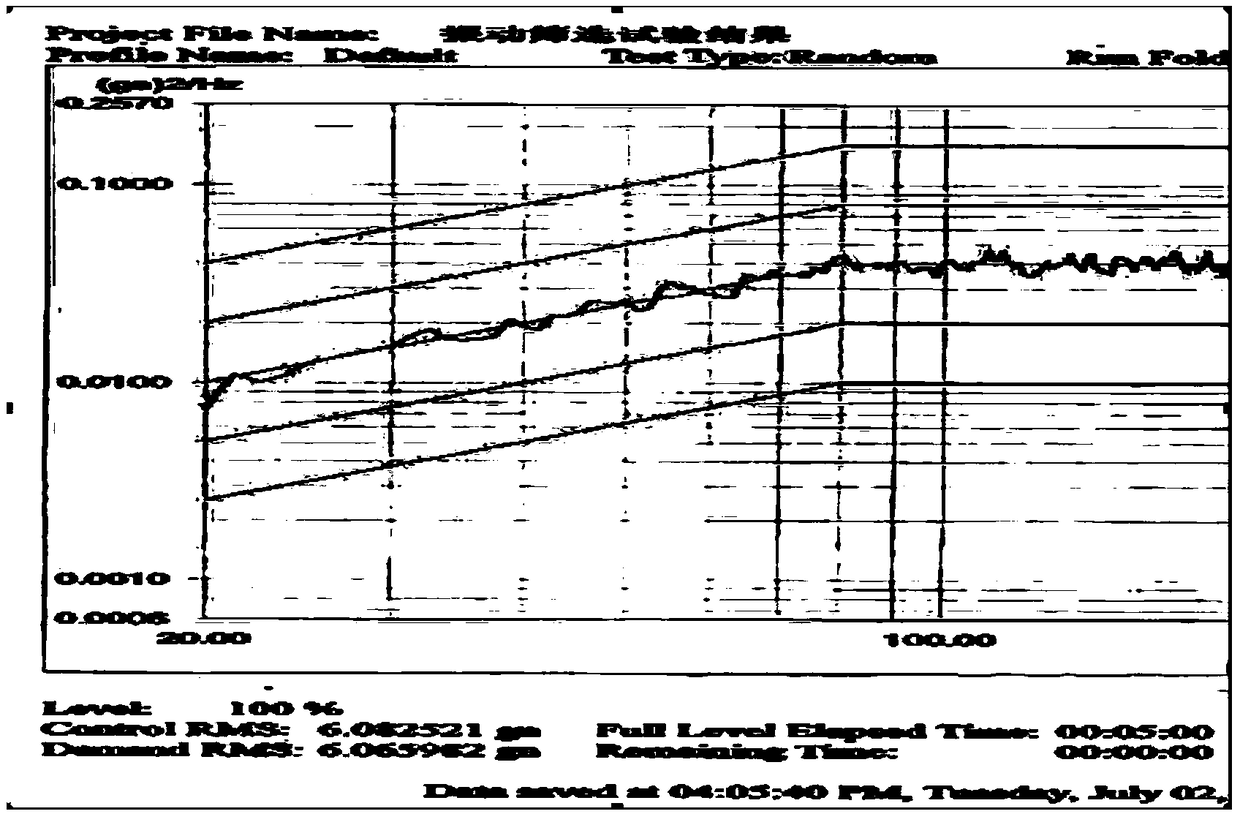

[0021] In this embodiment, the DHZ-29 electric ignition device is used as an example to carry out the horizontal sliding table + X-direction random vibration test. The product requirements are in accordance with Article 5.2 of "Electronic Product Environmental Stress Screening Method" (No.: GJB1032-90), and the test values are as follows: figure 2 The test time is 5 minutes.

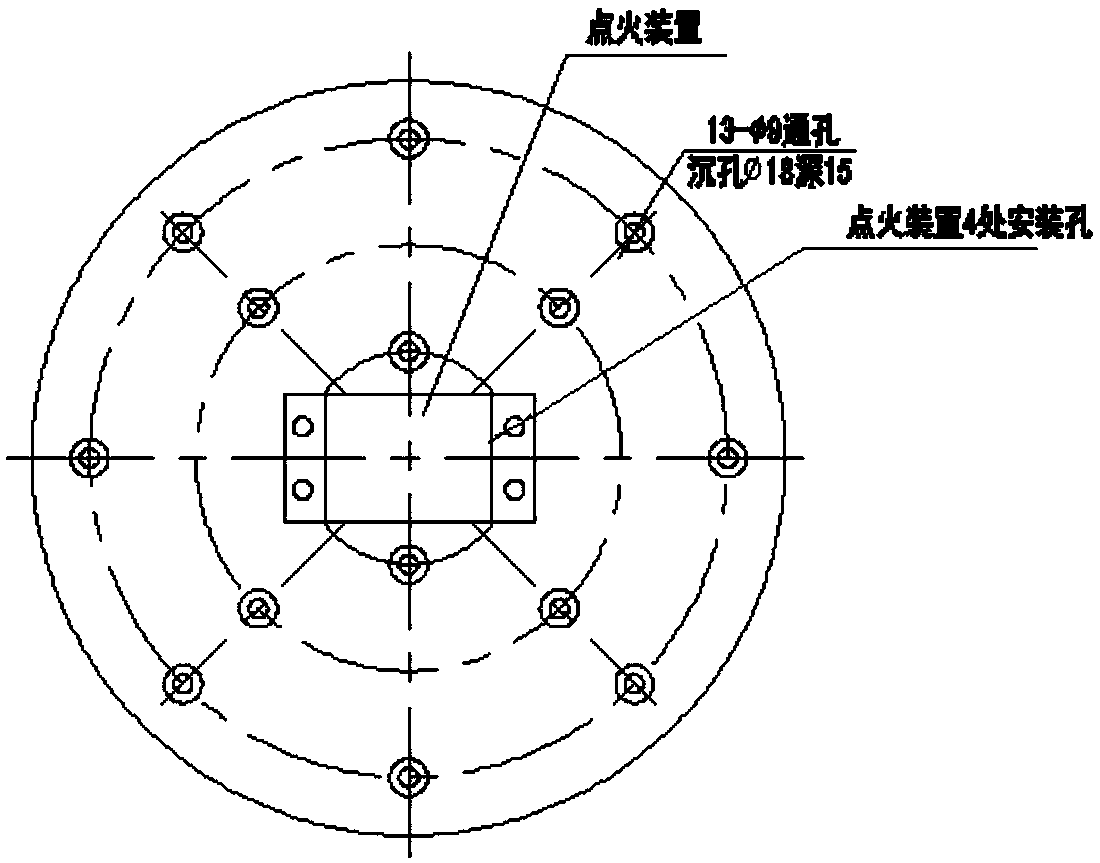

[0022] 1. Vibration fixture design

[0023] 1.1 Vibration fixture material: choose aluminum alloy and magnesium alloy with high rigidity and light weight. The DHZ-29 vibration fixture is made of aluminum alloy, the material grade is 5A06, the material standard is YS / T213-1994, and the plate thickness is (30±2)mm. Because the fixture made of aluminum alloy and magnesium alloy has hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com