Paper folding mechanism applied to solar back plate repair equipment

A solar backplane and equipment technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve the problems of reducing yield, waste, labor and time delay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

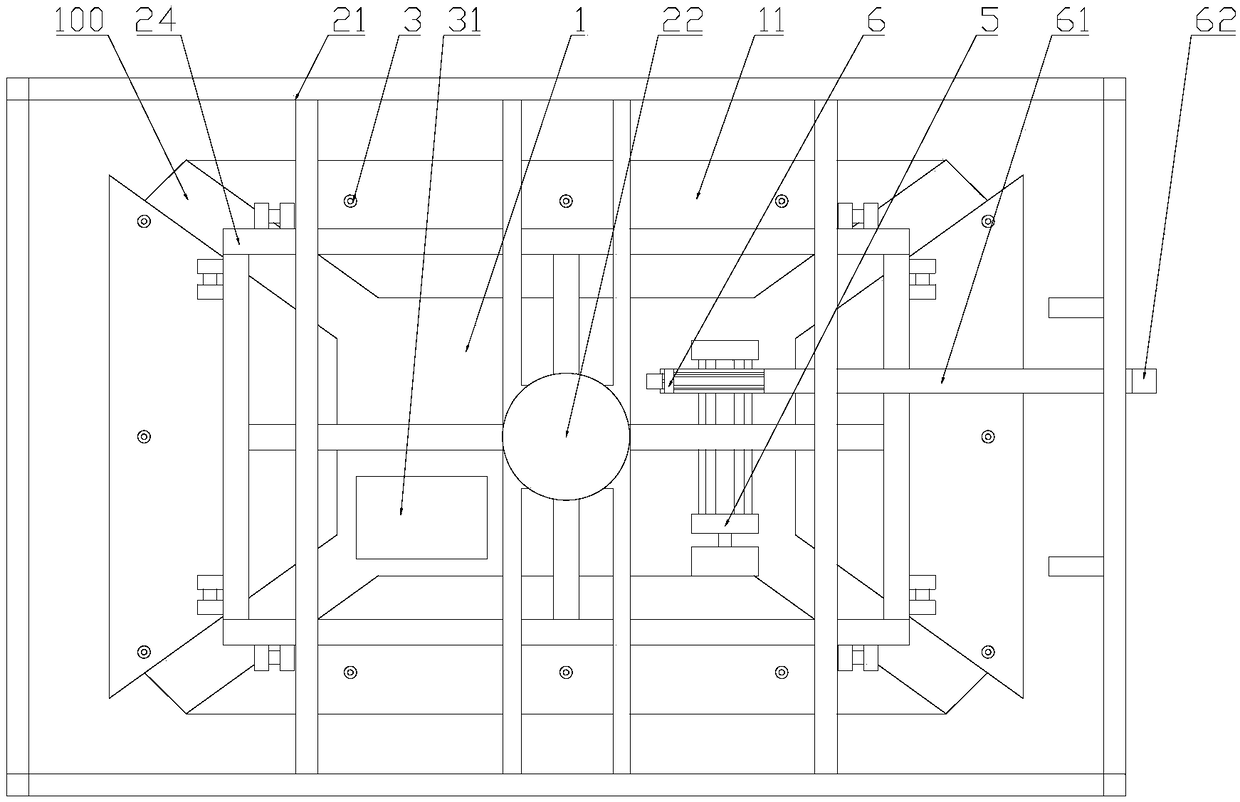

[0030] Such as figure 1 , figure 2 and image 3 As shown, an origami mechanism applied to solar backplane repair equipment includes a base plate 1, a blade 11 is rotated on the four sides of the base plate 1, and a base plate 1 between two adjacent blades 11 is provided with The baffle 100, the base plate 1, the four baffles 100 and the four blades 11 together form a grasping workbench. The shape of the blades 11 is trapezoidal, which ensures that the folding mechanism can absorb the protective paper.

[0031] The top surface of the substrate 1 is fixed with a polished rod 2, and the top of the polished rod 2 is provided with a support frame 21 connected with the transmission mechanism of the solar back panel repairing machine. The support frame 21 can ensure the overall movement of the origami mechanism.

[0032] A servo motor 22 is arranged on the support frame 21 , and a threaded rod 23 axially connected with the working rod of the servo motor 22 is rotatably arranged on...

Embodiment 2

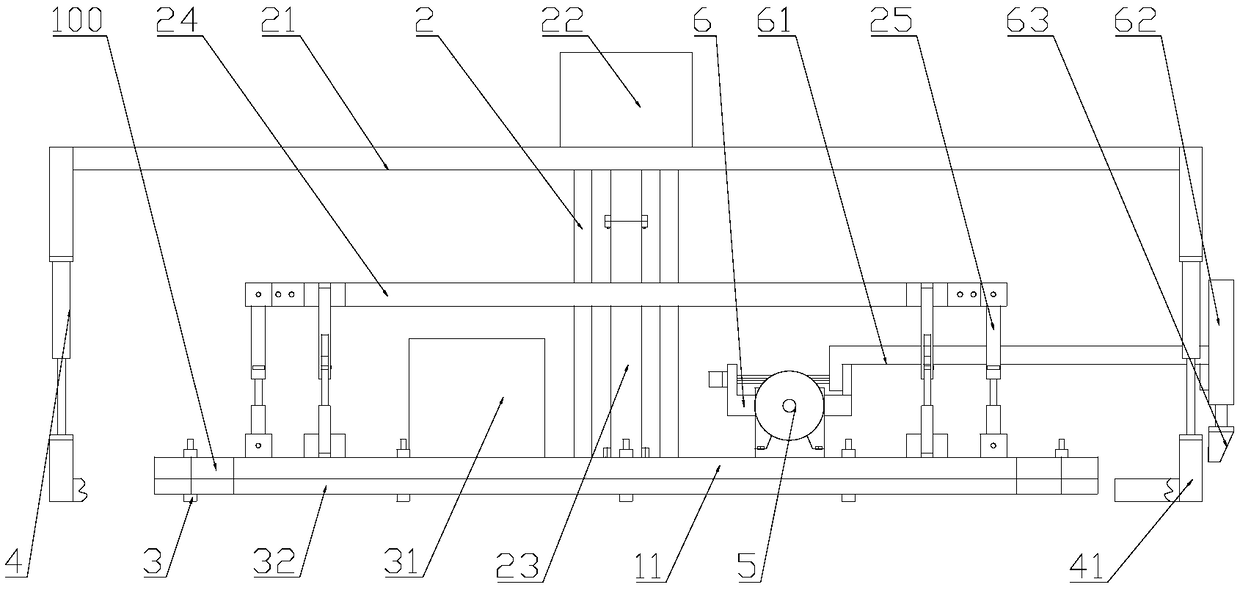

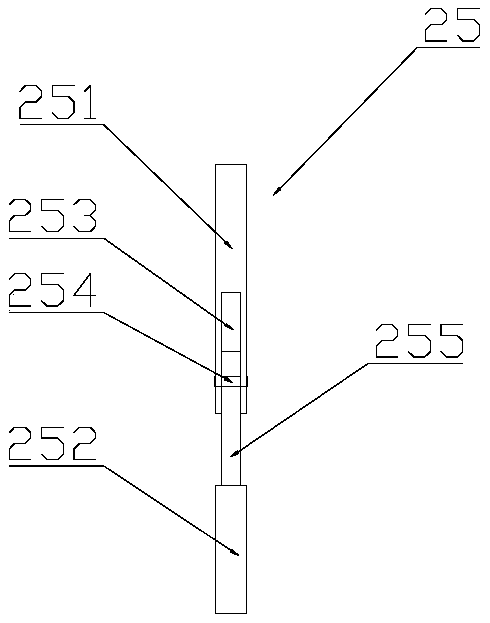

[0044] Such as Figure 4 and Figure 5 As shown, compared with Embodiment 1, the difference is that the number of servo motors 22 is four, and the servo motors 22 are arranged on the support frame 21 on the top of the four sides of the substrate 1, and the substrate 1 is rotated to be provided with four motors and four motors respectively. The working rods of the servo motors 22 are axially connected to the screw rods 23, and two polished rods 2 are arranged between the support frame 21 on both sides of each screw rod 23 and the substrate 1, and the two polished rods 2 on the same side of the substrate 1 The upper slide is provided with a bracket 24 sleeved on the screw rod 23. The bracket 24 is parallel to the base plate 1. A connecting rod 25 is installed on each of the four brackets 24. The ends of the four connecting rods 25 rotate with the four blades 11 respectively. Connected so that each blade 11 can rotate up and down independently; in order not to affect the cut on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com