Injector

A technology for syringes and syringes, applied in the field of syringes, which can solve the problems of cumbersome use of syringes and easy contamination of needles, and achieve the effects of rapid loading of liquid medicine, prevention of leakage and pollution, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

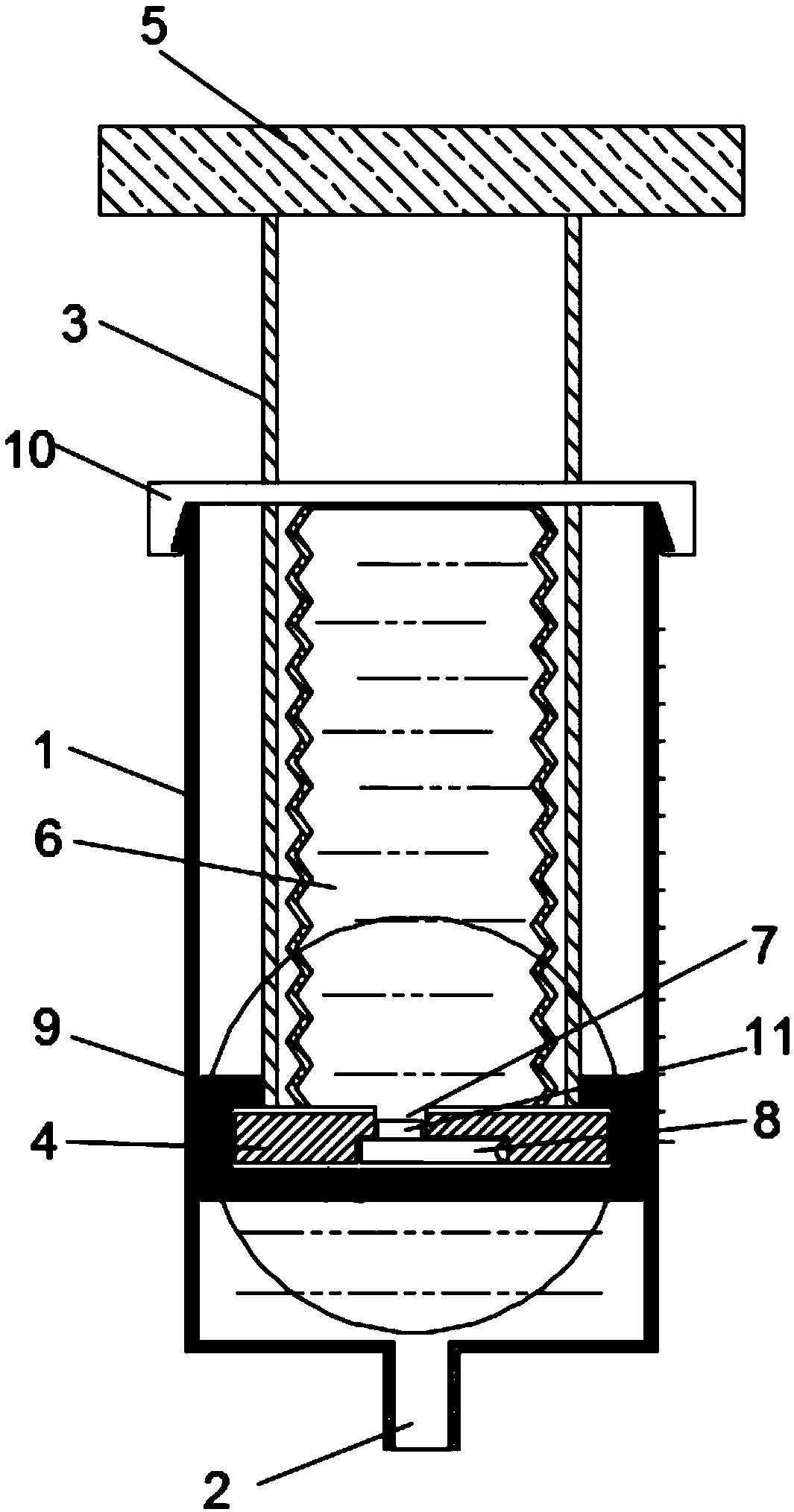

[0026] like figure 1 As shown, the present embodiment provides a syringe, which includes a syringe 1 and a needle connecting portion 2 arranged at the end of the syringe 1. A piston assembly is arranged inside the syringe 1, and the piston assembly includes a hollow push rod 3, which is pushed The end of the rod 3 close to the needle connection part 2 is provided with a piston plate 4, the end of the push rod 3 away from the needle connection part 2 is provided with a push handle 5, the push handle 5 is located outside the syringe 1, and the inside of the push rod 3 is provided with a liquid storage The cylinder 6, the opening end of the liquid storage cylinder 6 is fixedly connected with the piston plate 4, the piston plate 4 is provided with a through hole 7, and the end of the through hole 7 near the needle connection part 2 is provided with a one-way valve 8, and the piston plate 4 is covered outside A rubber sleeve 9 is provided, the rubber sleeve 9 below the one-way valv...

Embodiment 2

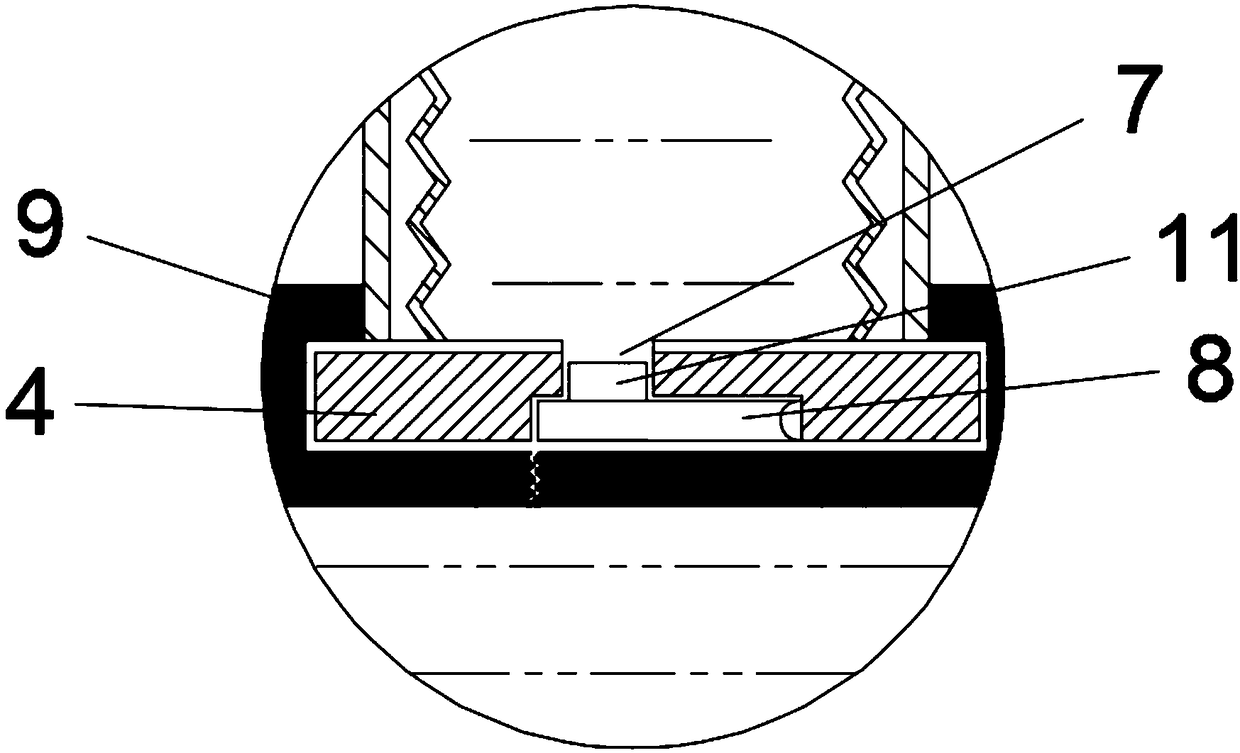

[0030] like figure 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the one-way valve 8 includes a valve plate, which is hinged to the bottom of the piston plate 4. When the valve plate rotates upward, it is blocked by the bottom of the piston plate 4, so It can only be rotated downwards to play the role of guiding check valve 8.

[0031] As a preferred manner, a blocking block 11 extending into the through hole 7 is provided on the top of the valve plate, and the blocking block 11 is provided to further prevent the liquid inside the liquid storage cylinder 6 from leaking.

[0032] As a preferred method, the slit is U-shaped. Specifically, the U-shaped bend corresponds to the hinged end of the valve plate, and the U-shaped opening corresponds to the movable end of the valve plate. The U-shaped slit is set so that the rubber The bottom of the sleeve 9 can form a hinged rubber part that rotates around the U-shaped bend to adapt to th...

Embodiment 3

[0035] like figure 1 and figure 2 As shown, this embodiment is further optimized on the basis of Embodiment 2. Specifically, there are two strip-shaped through grooves symmetrical to the central axis of the push rod 3 on the side wall of the push rod 3, and the baffle plate 10 runs through the two The strip-shaped through groove is clamped with the end of the injection barrel 1. The strip-shaped through groove can guide the up and down movement of the push rod 3, so that the push rod 3 can move up and down freely, and the clamped baffle 10 is set to make the baffle 10 The liquid storage bottle can be squeezed, and at the same time, the push rod 3, the baffle plate 10 and the syringe 1 can be disassembled conveniently.

[0036] In the syringe of the present invention, when it is in the initial state, that is, when it is not in use after the manufacture is completed, the rubber sleeve 9 should be in contact with the bottom of the injection cylinder 1, so that the one-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com