Multilayer-multiball magnetic positioning type tooth pitch sample plate and magnetic force design method thereof

A magnetic positioning and tooth pitch technology, applied in the field of standard devices, can solve the problem of not being able to assemble into different forms of tooth pitch templates, and achieve the effects of simplifying the structure, improving the precision, and reducing the processing and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

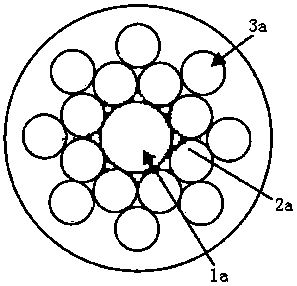

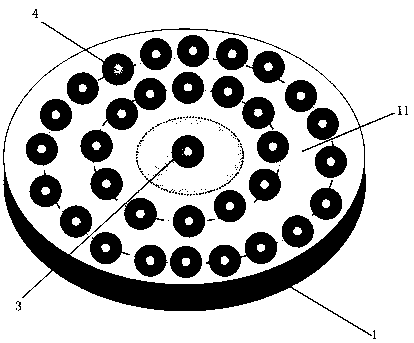

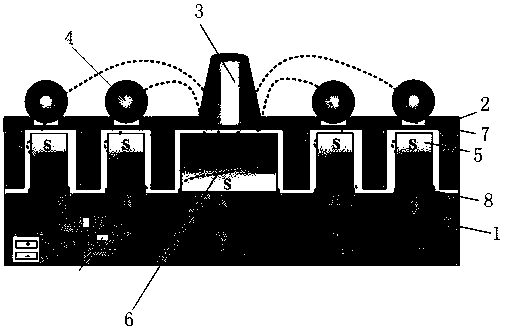

[0049] Such as figure 2 As shown, a multi-layer-multi-sphere magnetically positioned tooth pitch template includes a base 1 whose upper surface is a base plane 11, and a concave hole for placing and positioning a centering cylinder / sphere / cone 3 is opened on the base plane 11. Groove; around the center of the centering cylinder / sphere / cone 3 on the base plane, there are at least two layers of positioning holes arranged in a ring at intervals from the inside to the outside; the center of each positioning hole on each layer of positioning holes is located in the base plane for centering The horizontal projection of the central point of the cylinder / sphere / cone is the center, on a circular curve with the radius of the pitch circle of the virtual gear as the radius; the number of positioning holes in each layer is consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com