PE (polyethylene) hot melt glue electric smelting casing

A technology of electric hot melt and hot melt adhesive, which is applied in the field of pipeline facilities, can solve the problems of low work efficiency, poor strength, running, dripping, and leaking at the joint, and achieve the effects of reducing labor intensity, improving connection strength, and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

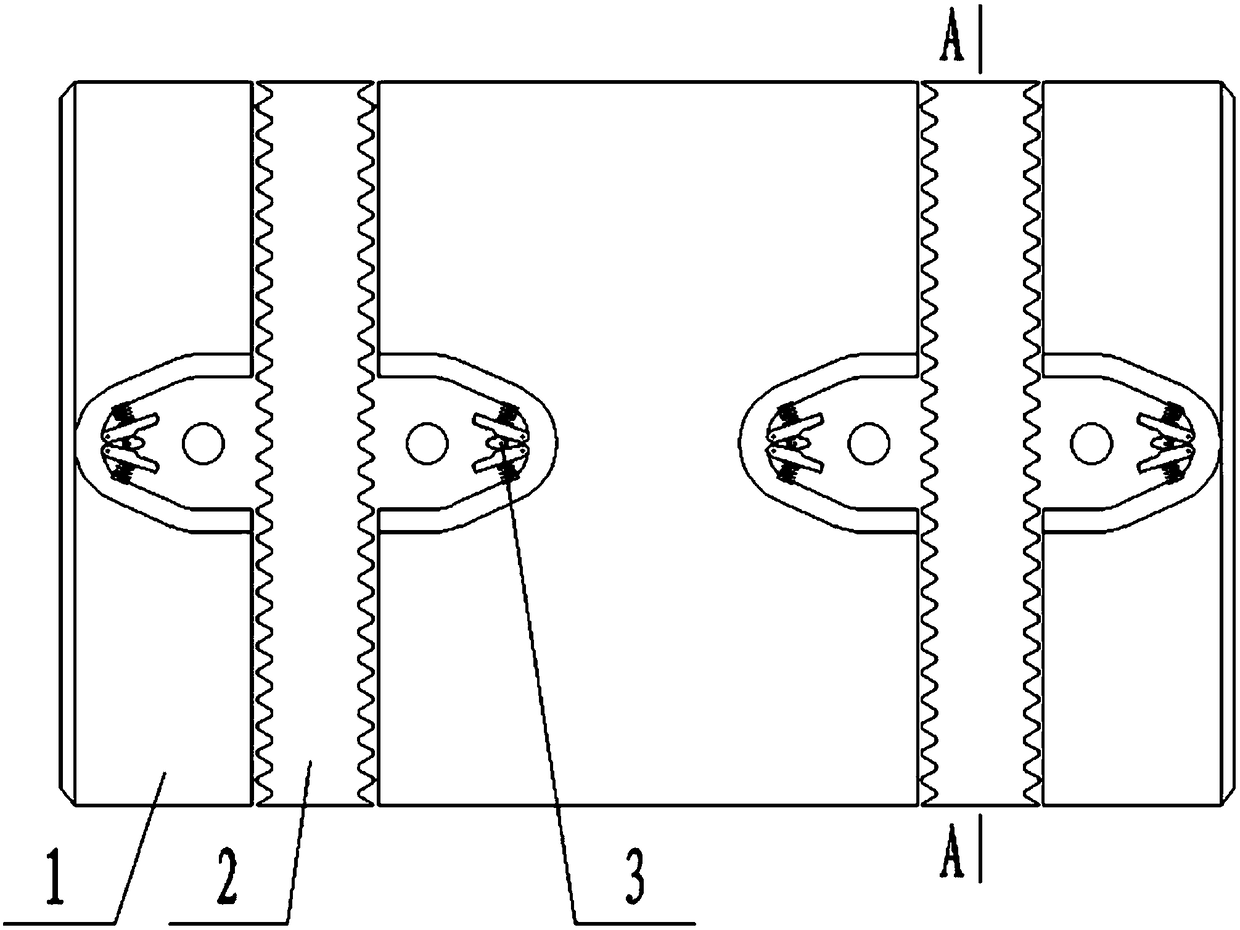

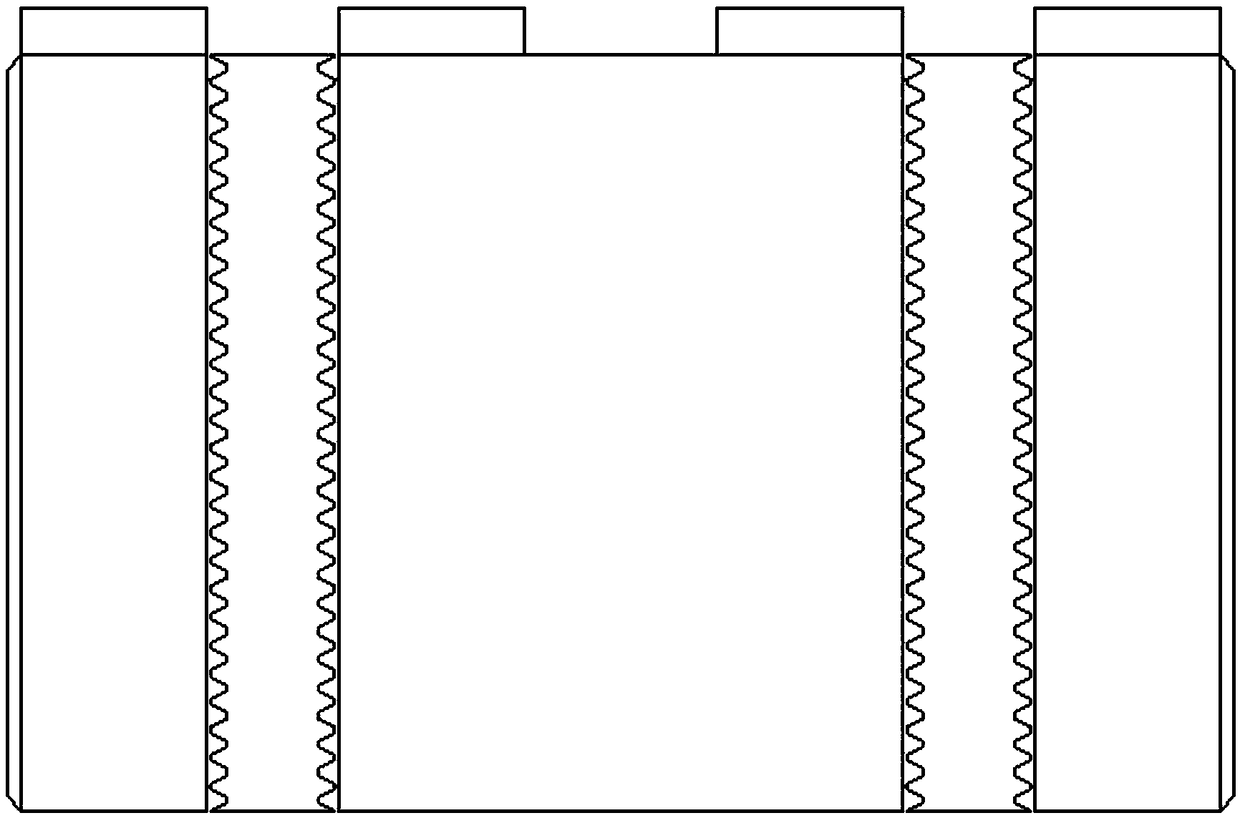

[0021] This embodiment includes a joint body 1 , and a heating wire is arranged on the inner wall of the joint body 1 . The above are common structures in the prior art, and will not be repeated here.

[0022] The main innovations of the present invention are:

[0023] The two ends of the joint body 1 are each provided with a reinforcement and centralization device, through which the joint of the pipeline can be reinforced to improve the connection strength, and at the same time, the PE pipeline inside the joint body 1 is centered and centralized to improve the connection between the pipeline and the joint. The centering of the joint body 1 improves the quality of pipe connection.

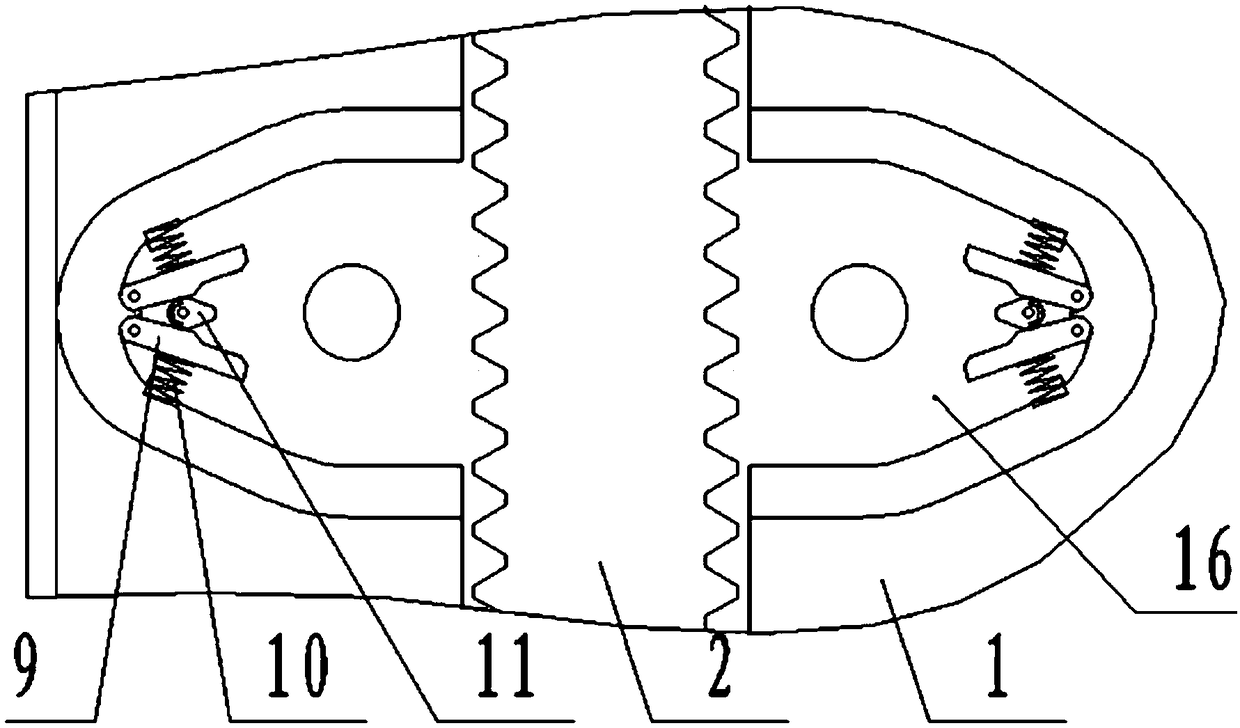

[0024] The structure of the reinforcing and centralizing device includes a ring gear 2, a locking pin 6 and a backstop mechanism 3. The ring gear 2 is installed in an annular groove outside the joint body 1, and the ring gear 2 can rotate around the annular groove. There are at least three lockin...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is that: as an alternative, the axis of the locking nail 6 is perpendicular to the guide slope 8 . Compared with Embodiment 1, when adopting the above-mentioned technical scheme, the head of the locking nail 6 only bears the frictional force applied by the guiding slope 8, and does not bear the overturning moment applied by the guiding slope 8. Therefore, this locking nail 6 The arrangement can not only make the locking nail 6 move more smoothly, but also effectively prevent the locking nail 6 from falling over.

[0037] The present invention is provided with a locking nail 6 structure, and the locking nail 6 can be pressed into the joint body 1 by rotating the ring gear 2. This structural form solves two problems: on the one hand, after the construction is completed, the upper end of the locking nail 6 is inserted On the joint body 1, the lower end of the locking nail 6 is inserted into the connected PE pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com