A new type of pod for air cargo

A technology for carrying objects and pods, which is applied in transportation, packaging, and aircraft parts, etc. It can solve the problems of long transition period, out-of-synchronization of pilot transition time and unfavorable flight training, etc., and achieve good overall and local stiffness , enhance the overall structural strength and safety performance, and reduce the effect of assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

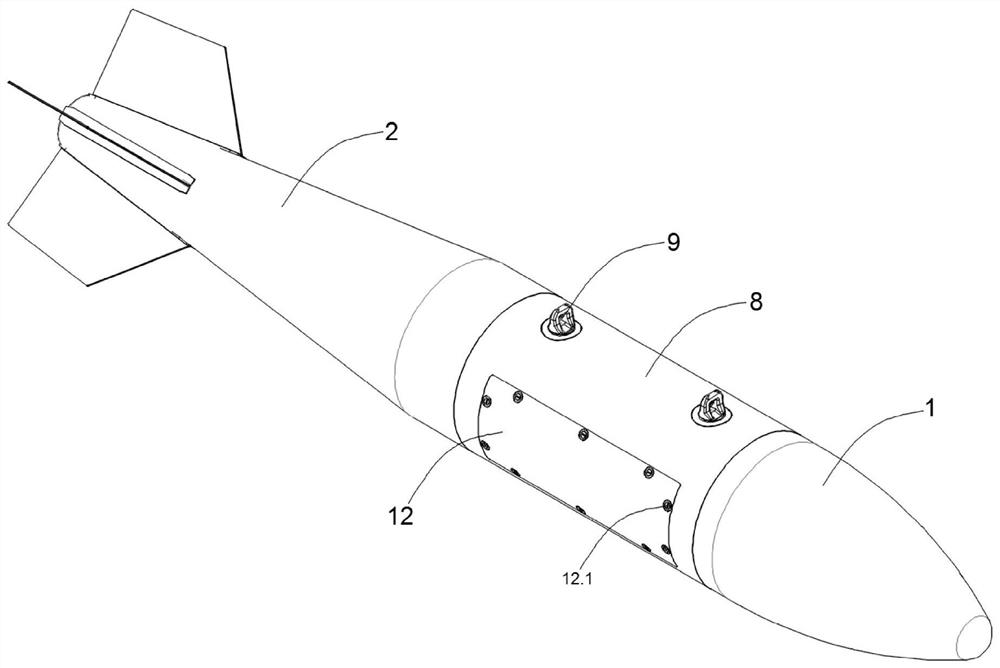

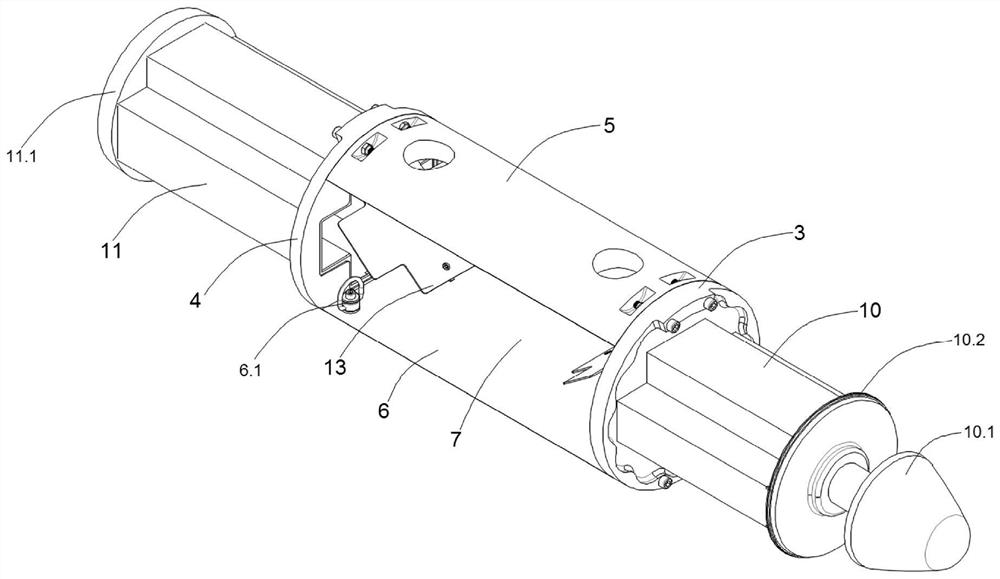

[0026] Such as figure 1 As shown, a new type of pod for air cargo, including a skeleton assembly, a fairing and a number of doors, the fairing is composed of a front fairing 1 and a rear fairing 2, and the skeleton assembly includes a disc-shaped The front flange 3 and the rear flange 4 are fixed with the lower bearing beam 6 and the upper bearing beam 5 as the main bearing part of the whole pod between the front flange 3 and the rear flange 4, and the upper bearing A cargo compartment 7 for storing accompanying luggage is formed between the force beam 5 and the lower force beam 6, and a skin panel 8 is arranged on the outside. The skin panel 8 is in the shape of a column shell and its two ends are respectively welded to the front flange 3 and on one side of the rear flange 4, the upper bearing beam 5 is provided with two lifting lugs 9 passing through the skin panel 8 and connected with the aircraft, and the other side of the front flange 3 is fixed with a file compartment 10...

Embodiment 2

[0029] Such as figure 1 As shown, this embodiment is further optimized on the basis of embodiment 1, specifically:

[0030] The front fairing 1 and the rear fairing 2 are streamlined to meet the requirements of the aerodynamic load and are respectively welded on the front flange 3 and the rear flange 4. The front fairing 1 and the rear fairing 2 are respectively connected to the skin panel 8 connected at both ends.

[0031] File cabin 10 ends are fixed with pod head 10.1 wrapped by front fairing 1, between pod head 10.1 and file cabin 10, are fixed with the front connecting plate 10.2 that supports front fairing 1, tool cabin 11 1。 The end is fixed with a rear connection plate 11.1 supporting the rear fairing 2.

[0032] The fairing is designed to be streamlined to reduce resistance and better meet aerodynamic requirements, and the fairing is welded to reduce the number of rivets, thereby reducing the workload of assembly; the fairing is connected to the middle skin panel 8 ...

Embodiment 3

[0034] in such as Figure 1 to Figure 2 As shown, this embodiment is further optimized on the basis of embodiment 2, specifically:

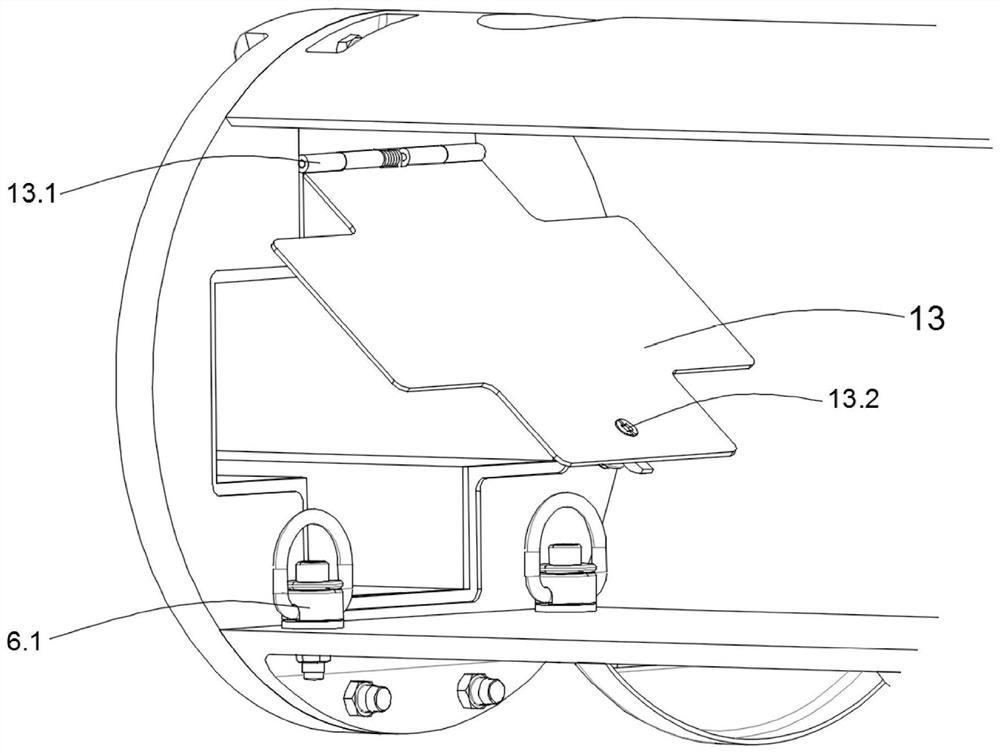

[0035] The auxiliary hatch 13 on the front flange 3 and the rear flange 4 is the same as the cross-sectional size and shape of the document cabin 10 and the tool cabin 11 respectively, and the top of the auxiliary hatch 13 is fixed on the flange by the hatch hinge 13.1 2。 On the plate, the bottom of the auxiliary hatch 13 is fixed with a cover lock 13.2 for opening and closing the hatch.

[0036] The size and shape of the auxiliary hatch door 13 are the same as the cross-sectional size and shape of the corresponding cabin, which is convenient for loading and unloading materials, and improves the efficiency of material loading and unloading. The auxiliary hatch door 13 is provided with hatch hinges 13.1 and flap locks 13.2, and the structure is simple , Easy to open and close.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com