Self-regenerative rectification system and recovery method for dimethylformamide

A technology of dimethylformamide and rectification system, which is applied in the field of dimethylformamide self-regenerating rectification system and recovery, can solve problems such as increased equipment investment, save operating costs, shorten process flow, save steam and The effect of the use of circulating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

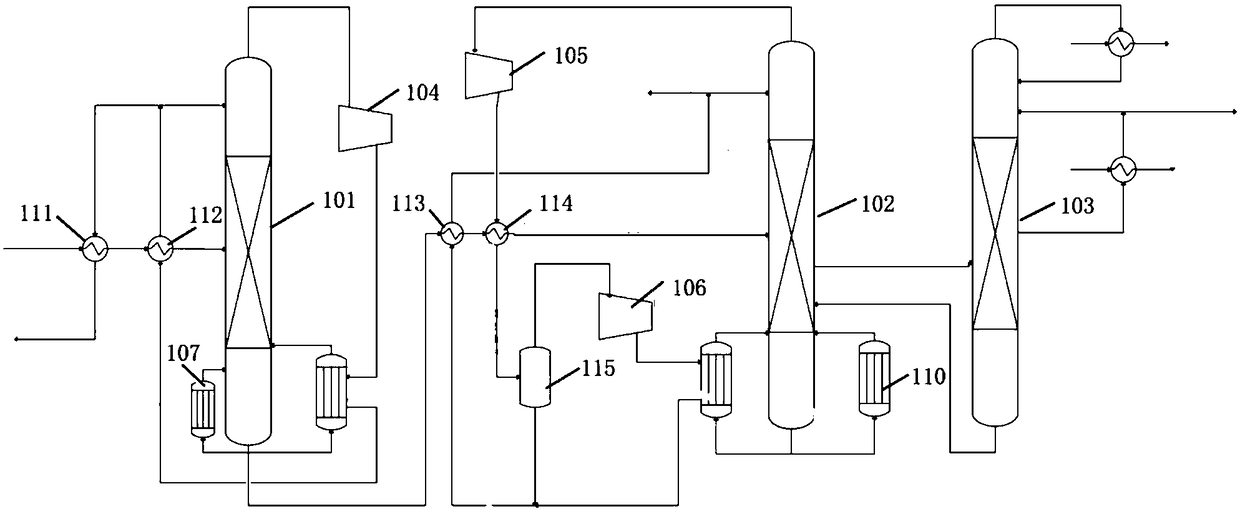

[0027] A self-regenerating rectification system for dimethylformamide, comprising: a dehydration tower 101, a refining tower 102 and a deacidification tower 103, a first steam outlet between the top steam outlet of the dehydration tower 101 and the heat source inlet of the reboiler of the tower kettle A compressor 104 is provided with a secondary preheater between the inlet of the tower top reflux tank (not shown) of the dehydration tower and the heat source outlet of the tower still reboiler of the tower, for dehydration tower feed and from The tower top steam flowing out of the reboiler of the tower is used for heat exchange, and a first-stage preheater is arranged before the second-stage preheater, which is used for heat exchange between the feed of the dehydration tower and the material extracted from the tower top reflux tank of the tower. A tertiary preheater 113 is arranged between the discharge port of the dehydration tower bottom and the feed port of the refining tower...

Embodiment 2

[0035]A self-regenerating rectification system for dimethylformamide, comprising: a dehydration tower 101, a refining tower 102 and a deacidification tower 103, a first Compressor 104 is provided with a secondary preheater 112 between the inlet of the tower top reflux tank of the dehydration tower and the heat source outlet of the tower kettle reboiler of the tower, which is used for dehydration tower feed and reboiler from the tower The outgoing steam at the top of the tower is used for heat exchange, and a first-stage preheater 111 is provided before the second-stage preheater, which is used for heat exchange between the feed of the dehydration tower and the material extracted from the tower top reflux tank of the tower. A tertiary preheater 113 is arranged between the discharge port of the dehydration tower bottom and the feed port of the refining tower, and is used for preheating the feed of the refining tower with the top steam flowing out from the reboiler of the refining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com