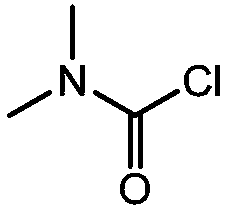

Preparation method of dimethylcarbamoyl chloride

A technology of dimethylcarbamoyl and dimethylamine, which is applied in the field of preparation of dimethylcarbamoyl chloride, can solve the problems of difficult separation of toluene and products, low yield, cumbersome operation, etc., and achieve good application value and application prospect , simple operation, high content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

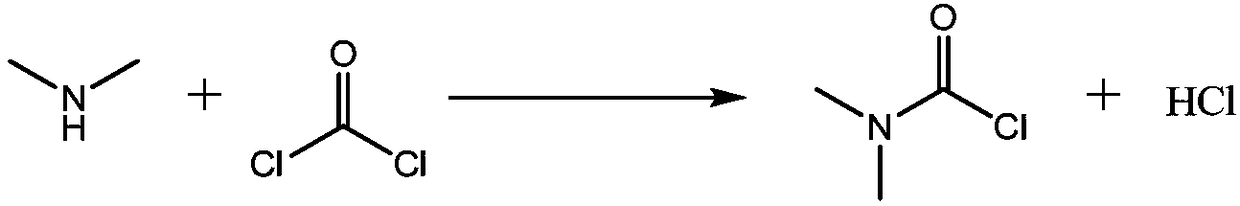

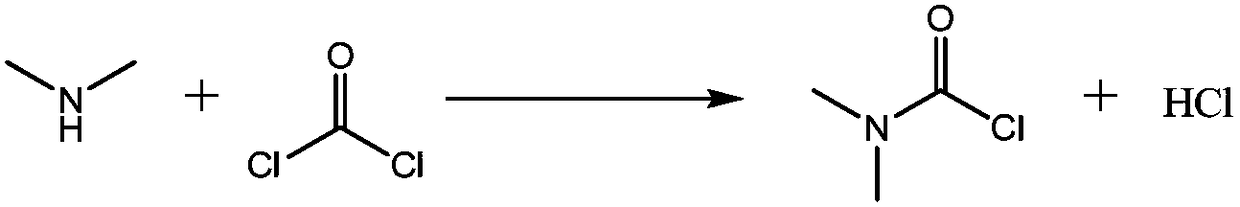

Method used

Image

Examples

Embodiment 1

[0024] The invention relates to a preparation method of dimethylcarbamoyl chloride. A microreactor is used as a reaction device, and dimethylamine and phosgene are simultaneously passed into the microreactor for reaction to obtain dimethylcarbamoyl chloride. Include the following steps:

[0025] A microreactor with 8 reaction templates was used as the reaction device, and the temperature of each reaction module in the microreactor was controlled at 190 °C. By gas mass flow meter, 136.4g dimethylamine (99.0%, 3.0mol) is passed in the microreactor with the speed of 68.2g / min, simultaneously with 371.3g phosgene (80%, 3.0mol) with the speed of 185.7g / min mol) into the microreactor, mixed and reacted; after the reaction was completed, the obtained gas material was cooled to room temperature and condensed with a cooling device, and the cooled liquid material was collected to obtain 325.4g dimethylcarbamoyl chloride crude product; After distillation, 310.1 g of dimethylcarbamoyl ch...

Embodiment 2

[0027] The invention relates to a preparation method of dimethylcarbamoyl chloride. A microreactor is used as a reaction device, and dimethylamine and phosgene are simultaneously passed into the microreactor for reaction to obtain dimethylcarbamoyl chloride. Include the following steps:

[0028] A microreactor with 8 reaction templates was used as the reaction device, and the temperature of each reaction module in the microreactor was controlled at 190 °C. Through the gas mass flow meter, 136.4g dimethylamine (99.0%, 3.0mol) is passed in the microreactor with the speed of 68.2g / min, simultaneously with the speed of 204.2g / min 408.4g phosgene (80%, 3.3 mol) into the microreactor, mixed and reacted; after the reaction was completed, the obtained gas material was cooled to room temperature with a cooling device, condensed, and the cooled liquid material was collected to obtain 324.1g dimethylcarbamoyl chloride crude product; After distillation, 311.8g of dimethylcarbamoyl chlori...

Embodiment 3

[0030] The invention relates to a preparation method of dimethylcarbamoyl chloride. A microreactor is used as a reaction device, and dimethylamine and phosgene are simultaneously passed into the microreactor for reaction to obtain dimethylcarbamoyl chloride. Include the following steps:

[0031] A microreactor with 8 reaction templates was used as the reaction device, and the temperature of each reaction module in the microreactor was controlled at 200 °C. By gas mass flow meter, 136.4g dimethylamine (99.0%, 3.0mol) is passed in the microreactor with the speed of 27.3g / min, simultaneously with 371.3g phosgene (80%, 3.0mol) with the speed of 74.3g / min mol) into the microreactor, mixed and reacted; after the reaction was completed, the obtained gas material was cooled to room temperature and condensed with a cooling device, and the cooled liquid material was collected to obtain 326.7g of dimethylcarbamoyl chloride crude product; After distillation, 313.4g of dimethylcarbamoyl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com