Deodorizing detergent and preparation method thereof

A cleanser and emulsifier technology, which is applied in the field of preparation of the deodorant cleanser, can solve problems such as unsatisfactory sterilization and deodorization effects, poor deodorization effect, harmful environment, etc., and achieve good acid and alkali resistance and deodorization effect Good, good anti-hard water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

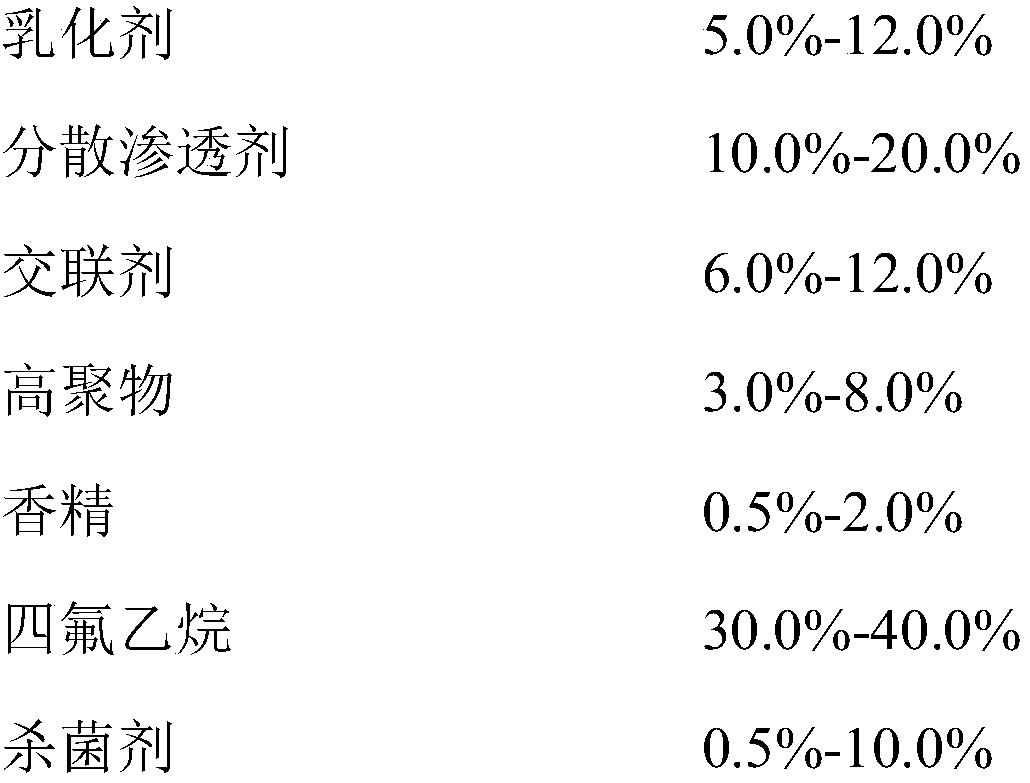

[0038] A deodorant cleanser, which consists of the following components in mass fraction:

[0039]

[0040]

[0041] The preparation method of above-mentioned deodorant cleaning agent, comprises the following steps:

[0042] Add dispersing penetrant, emulsifier and essence to the stainless steel reaction kettle, emulsify at room temperature for 1.5 hours, then add water and cross-linking agent; slowly raise the temperature to 45°C for 40 minutes, then add polymers for 30 minutes, cool down to Add fungicide and tetrafluoroethane at 35°C, react for 60 minutes; let stand overnight.

Embodiment 2

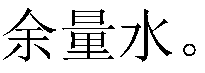

[0044] A deodorant cleanser, which consists of the following components in mass fraction:

[0045]

[0046] The preparation method of above-mentioned deodorant cleaning agent, comprises the following steps:

[0047] Add dispersing penetrant, emulsifier and flavor to the stainless steel reaction kettle, emulsify and react at room temperature for 1 hour, then add water and crosslinking agent; slowly raise the temperature to 50°C for 30 minutes, then add polymers for 40 minutes, cool down to Add fungicide and tetrafluoroethane at 40°C, react for 50 minutes; let stand overnight.

Embodiment 3

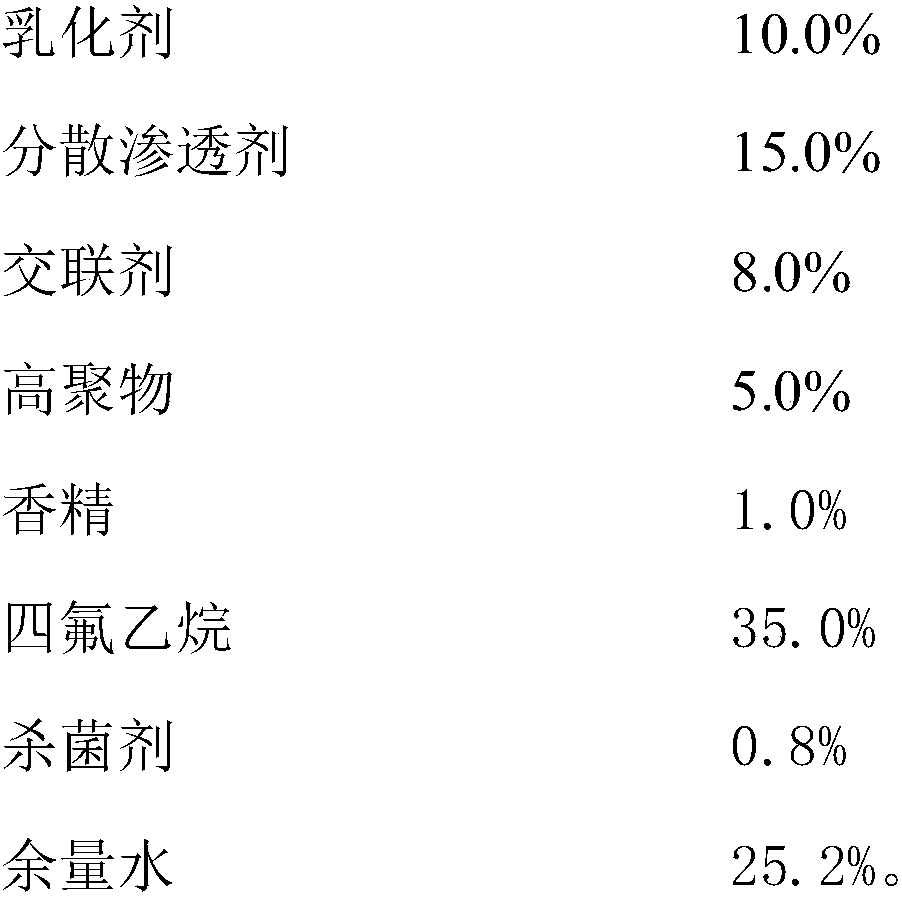

[0049] A deodorant cleanser, which consists of the following components in mass fraction:

[0050]

[0051] The preparation method of above-mentioned deodorant cleaning agent, comprises the following steps:

[0052] Add dispersing penetrant, emulsifier and flavor to the stainless steel reaction kettle, emulsify at room temperature for 1.2 hours, then add water and cross-linking agent; slowly raise the temperature to 47°C for 35 minutes, then add polymers for 35 minutes, cool down to Add fungicide and tetrafluoroethane at 37°C, react for 55 minutes; let stand overnight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com