Method of producing high-yield pattern-free galvanized sheet with yield strength of being 410MP or above

A 410MP, high-yield technology, applied in the field of high-yield pattern-free galvanized sheet, can solve the problems of large size fluctuation, unstable plate shape and performance, and shortened process flow of hot-dip galvanized sheet, and achieve good strength and plastic toughness Matching, good surface quality, shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for producing high-yield pattern-free galvanized sheets above 410MP. ESP process produces hot-rolled raw material coils. The composition is designed to be C: 0.20%, Si: 0.30%, Mn: 0.62%, P: ≤0.012%, S: ≤ 0.003%, Ti: 0.023%, Al: ≤0.02%, N: ≤0.033%;

[0041] The method comprises the steps of:

[0042] (1) Carry out converter and LF furnace smelting according to the above composition;

[0043] (2) Continuous casting control: superheat at start-up casting is 25°C, superheat at continuous pouring is 20°C, liquidus temperature is 1519°C, standard deviation of crystallizer liquid level fluctuation: ≤1.0mm; cross-sectional temperature difference of continuous casting slab: 35°C ;

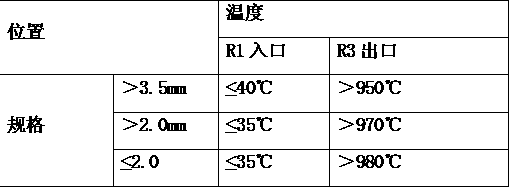

[0044] (3) Rough rolling, R1 inlet temperature 40°C, R3 outlet temperature 955°C;

[0045] (4) Outlet temperature of induction heating furnace: 1130±10°C;

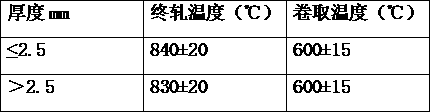

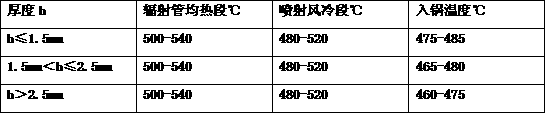

[0046] (5) Final rolling temperature and coiling temperature, final rolling temperature 855°C, coiling temperature 600±15°C;

[00...

Embodiment 2

[0059] A method for producing high-yield pattern-free galvanized sheets above 410MP. ESP process produces hot-rolled raw material coils. The composition is designed to be C: 0.17%, Si: 0.36%, Mn: 0.68%, P: ≤0.012%, S: ≤ 0.003%, Ti: 0.02%, Al: ≤0.02%, N: ≤0.033%;

[0060] The method comprises the steps of:

[0061] (1) Carry out converter and LF furnace smelting according to the above composition;

[0062] (2) Continuous casting control: superheat at start-up casting is 30°C, superheat at continuous pouring is 25°C, liquidus temperature is 1519°C, standard deviation of crystallizer liquid level fluctuation: ≤1.0mm; cross-sectional temperature difference of continuous casting slab: 30°C ;

[0063] (3) Rough rolling, R1 inlet temperature 35°C, R3 outlet temperature 975°C;

[0064] (4) Outlet temperature of induction heating furnace: 1130±10°C;

[0065] (5) Final rolling temperature and coiling temperature, final rolling temperature 840°C, coiling temperature 600±15°C;

[0066]...

Embodiment 3

[0077] A method for producing high-yield pattern-free galvanized sheets above 410MP. ESP process produces hot-rolled raw material coils. The composition is designed to be C: 0.23%, Si: 0.24%, Mn: 0.54%, P: ≤0.012%, S: ≤ 0.003%, Ti: 0.04%, Al: ≤0.02%, N: ≤0.033%;

[0078] The method comprises the steps of:

[0079] (1) Carry out converter and LF furnace smelting according to the above composition;

[0080] (2) Continuous casting control: superheat at start-up casting is 20°C, superheat at continuous casting is 15°C, liquidus temperature is 1519°C, standard deviation of crystallizer liquid level fluctuation: ≤1.0mm; cross-sectional temperature difference of continuous casting slab: 30°C ;

[0081] (3) Rough rolling, R1 inlet temperature 30°C, R3 outlet temperature 985°C;

[0082] (4) Outlet temperature of induction heating furnace: 1130±10°C;

[0083] (5) Final rolling temperature and coiling temperature, final rolling temperature 860°C, coiling temperature 600±15°C;

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com