Plug-in unit, plug-in connection, plug-in type steel pipe bundle and prefabrication and construction method of the plug-in type steel pipe bundle

A technology of steel pipe bundles and connecting units, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of long lap length, thick and dense steel bars, and the inability to use the strength of the web, etc., to achieve the effect of saving steel and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

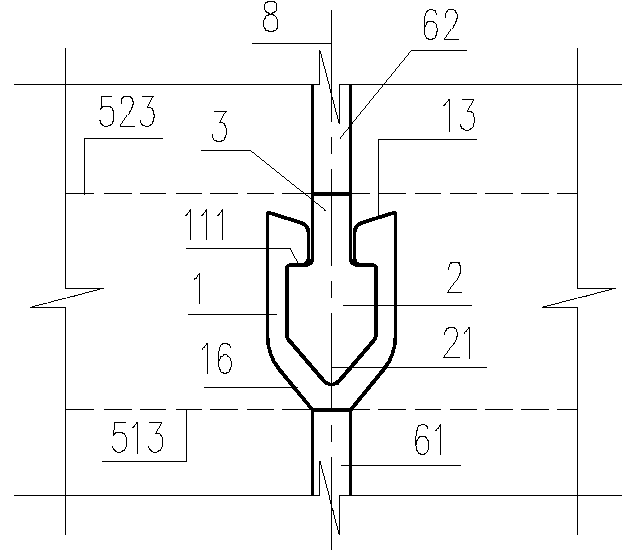

[0033] Such as figure 1 , 5 The plug-in units shown, including the buckle 1 and the plug 2, are all long linear shapes with a length greater than the cross section. In these two examples, a straight line is used; the middle of the buckle 1 has an accommodation space 11; there is an opening 12 along the length direction of the accommodation space 11, Its width is smaller than that of the accommodation space 11 , so that the plug 2 can be clamped in the accommodation space 11 and matched therewith.

[0034] In these two examples, the opening 12 is arranged on the top surface of the buckle 1, the first connected part 61 is connected to the bottom surface of the buckle 1, and the second connected part 62 is connected to the plug 2 through the opening 12, or connected to the handle 3 described below, The first and second connected parts 61 and 62 are tightly connected together through the plug 2 clamped in the accommodation space 11 to form a vertical 180° direct connection, which...

Embodiment 2

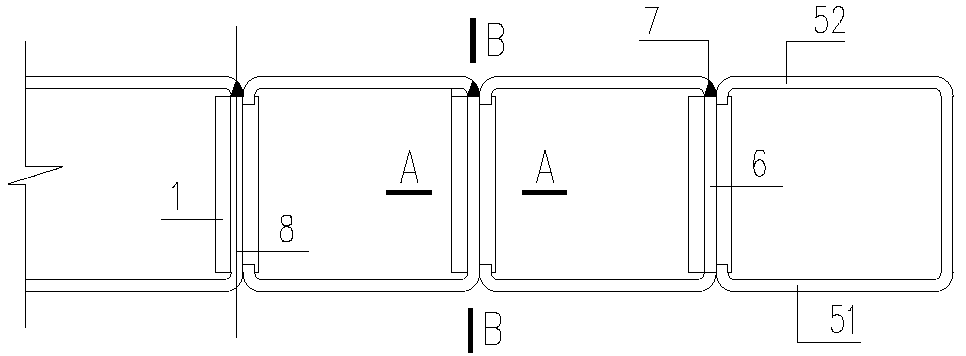

[0042] Such as Figure 2~4 , to adopt figure 1 The plug-in unit connects the steel pipe bundle assembly of the upper and lower steel pipe bundle webs. In this example, U-shaped steel units are arranged and connected in sequence to form steel pipes with cavities, which include a first flange 51, a second flange 52, and a web 6. The web 6 is a partition plate for adjacent steel pipes. . Connect the lower (steel tube bundle) web 61 and the upper (steel tube bundle) web 62 like the vertical 180° connection in Embodiment 1 to become a plug-in type steel tube bundle assembly, so that the web 6 can directly transmit the vertical Tension and compression can use the strength of the web.

[0043] Then connect the upper and lower first flanges 512, 511, connecting line 513; connect the upper and lower second flanges 522, 521, connecting line 523; then, pour concrete in the cavity of the steel pipe bundle, and other fillers can also be used. Such as grouting material, the filler squee...

Embodiment 3

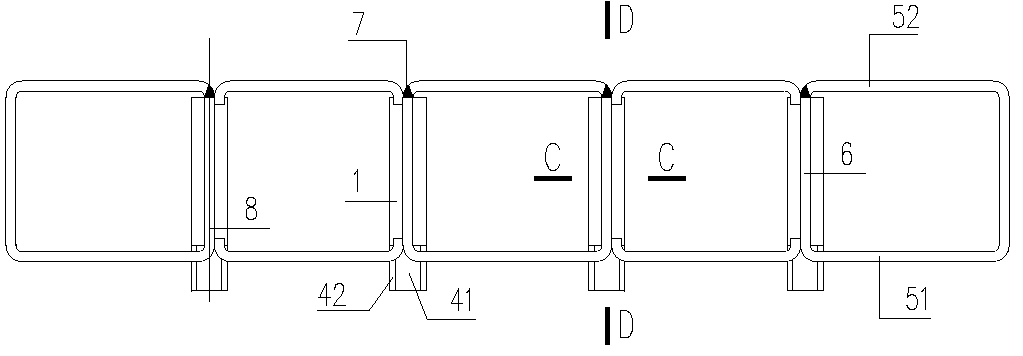

[0048] Such as Figure 6~8 for adoption Figure 5 The plug-in unit connects the steel pipe bundle assembly of the upper and lower steel pipe bundle webs. In this example, rectangular and plate steel units are arranged in turn to form a steel pipe bundle. The bottom surface of the mounting plate 4 is connected with the lower first flange 511, and the plug connection is according to the first embodiment Figure 4 It is explained that, after plugging, the mounting plate 4 is cut off from the outer surface of the flush first flange 51 , and the middle and upper surfaces 41 and 42 on both sides are connected to the upper first flange 512 . The positions of the connecting wires 513 and 523 are the same as that of the embodiment 2, which can be withdrawn and dismantled. The setting of the plug 2 and the buckle 1, the slit 7, the left and right symmetry axes of the section, and the application of structural glue are the same as the embodiment 2.

[0049] Because it is horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com