Energy consumption optimization method for double-variable hydraulic system under changing work conditions

A technology of hydraulic system and optimization method, which is applied in the directions of fluid pressure actuating system components, fluid pressure actuating devices, servo motors, etc. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

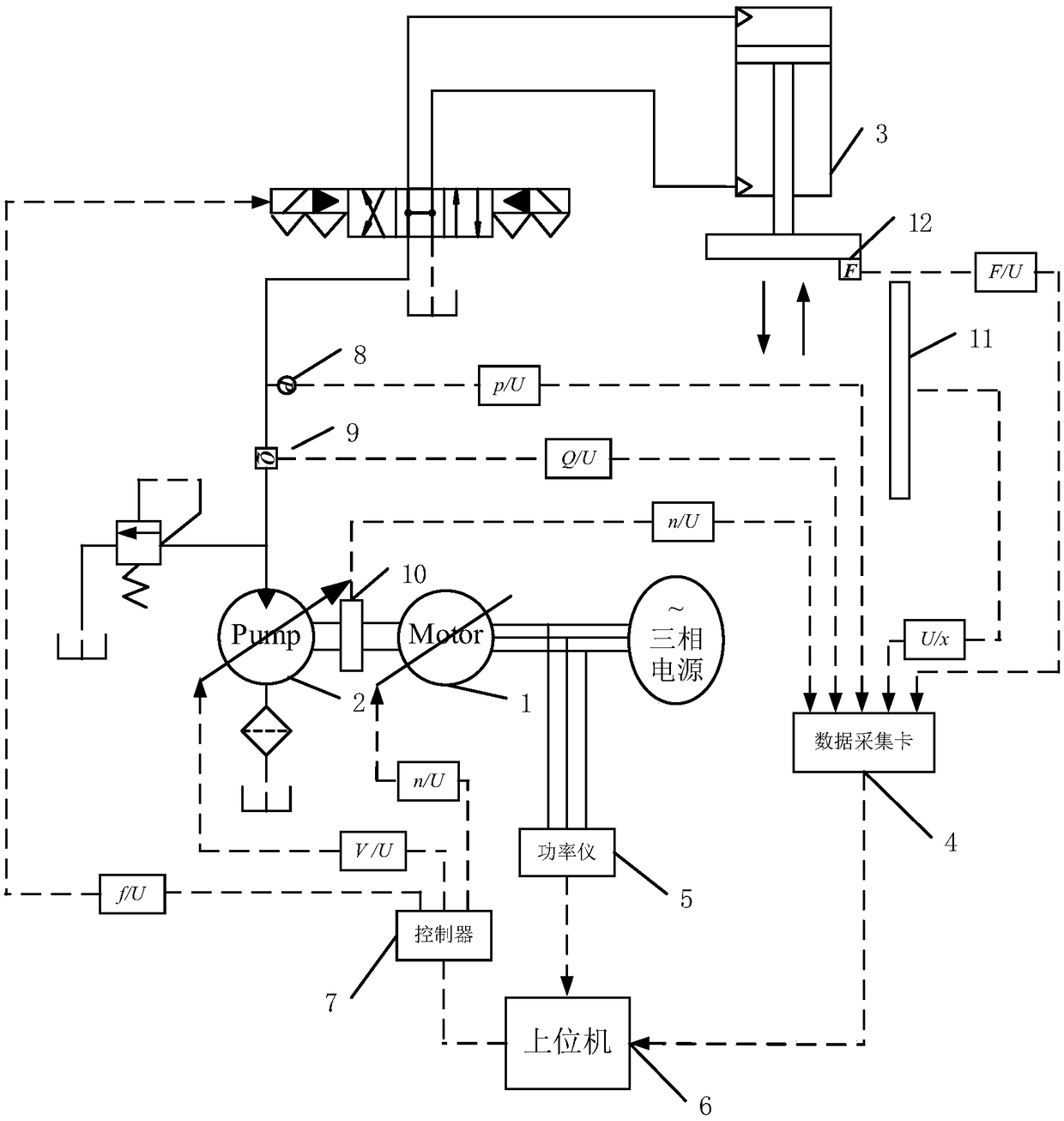

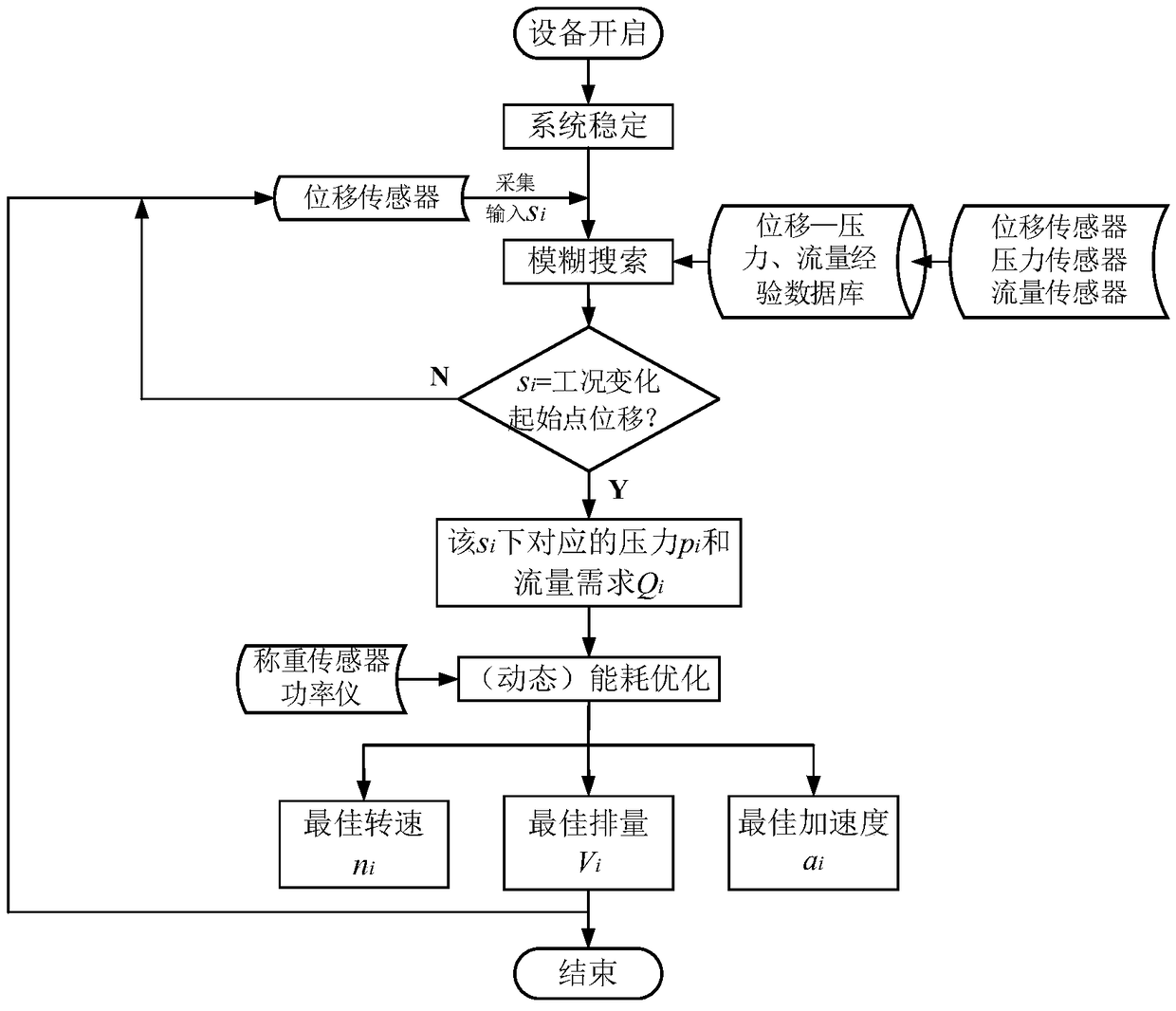

[0048] See figure 1 , The dual-variable hydraulic system in this embodiment includes: a hydraulic drive unit composed of a variable speed motor 1 and a variable pump 2, a hydraulic cylinder 3 driven by the hydraulic drive unit, and a control unit for controlling the speed of the variable speed motor 1 and the variable pump 2. Displacement controller 7; various sensors are provided, including: pressure sensor 8 for detecting hydraulic circuit pressure, flow sensor 9 for detecting hydraulic circuit flow, speed sensor 10 for detecting the speed of variable speed motor 1, and A power meter 5 for detecting the input power of the variable speed motor 1, a displacement sensor 11 for detecting the displacement of the hydraulic cylinder 3, and a force sensor 12 for detecting the load force received by the hydraulic cylinder 3, and a data acquisition card 4 for collecting For the detection signal of each sensor, the host computer 6 is set for signal processing for the collected signal, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com