High-precision on-line measuring and adjusting device for holographic grating period

A technology of holographic grating and adjustment device, which is applied in the direction of measuring device, optical instrument test, optics, etc., can solve the problems of measurement accuracy discount, affecting the density and direction of moiré fringes, etc., and achieve the effect of improving accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

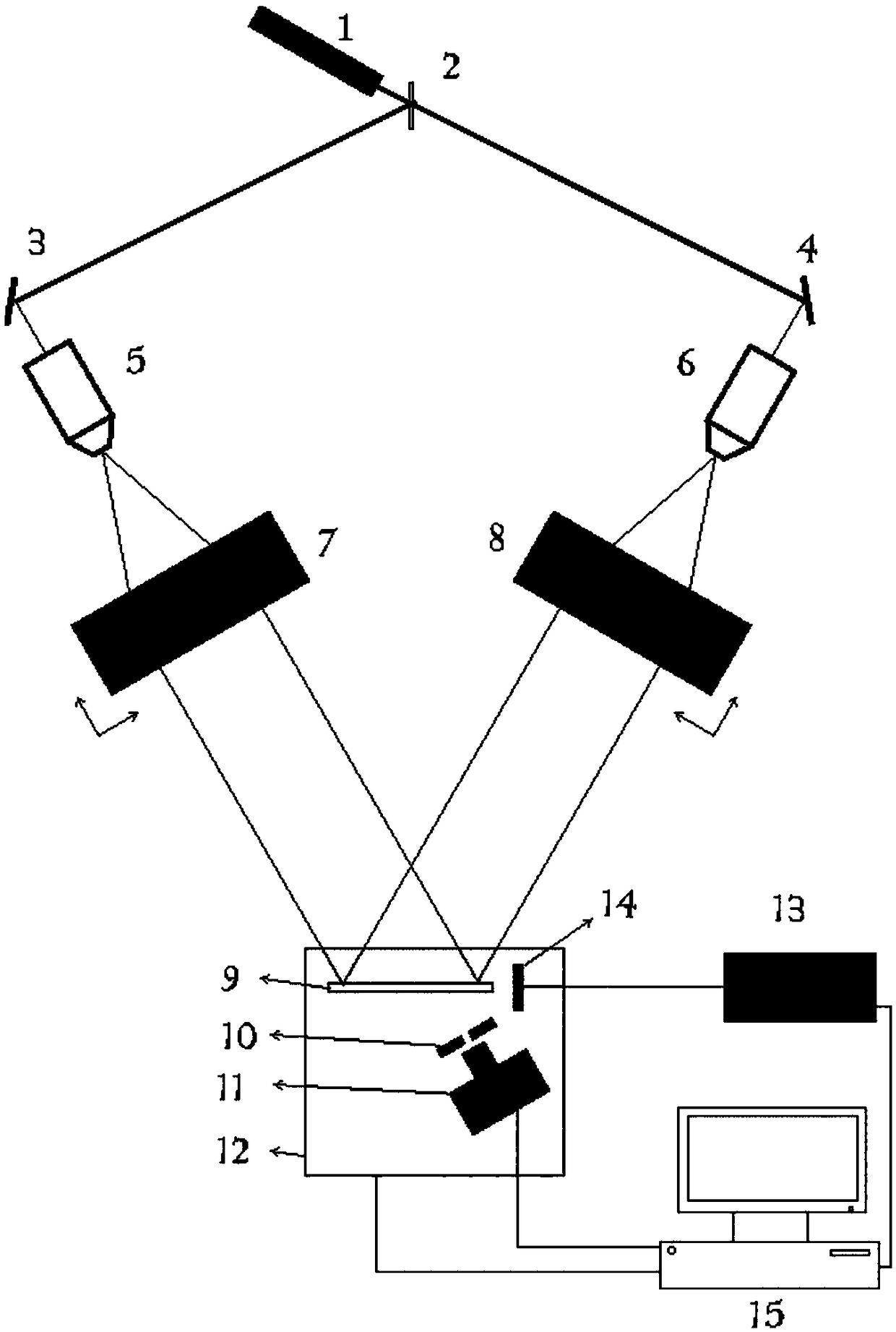

[0036] This embodiment discloses a high-precision online measurement and adjustment device for the period of a holographic grating, which includes: a double-beam holographic interference optical path for generating a high-density grating fringe field and capable of precise period adjustment; a reference grating and a photodetector, The reference grating is used to overlap a certain diffraction order of two beams of light to generate coaxial interference, thereby forming a stable interference field, and the photodetector is used to receive the light intensity information of the interference field; the high-precision one-dimensional mobile platform and laser interferometer System, the high-precision one-dimensional mobile platform is used to realize the movement of the grating and photodetector, and the laser interferometer is used to measure the displacement of the mobile platform with high precision; the synchronous control, data acquisition and processing system controls the ph...

Embodiment 2

[0047] The invention discloses a high-precision on-line measurement and adjustment device for the period of a holographic grating. There are various implementation methods according to the period of the holographic grating and the selection of devices.

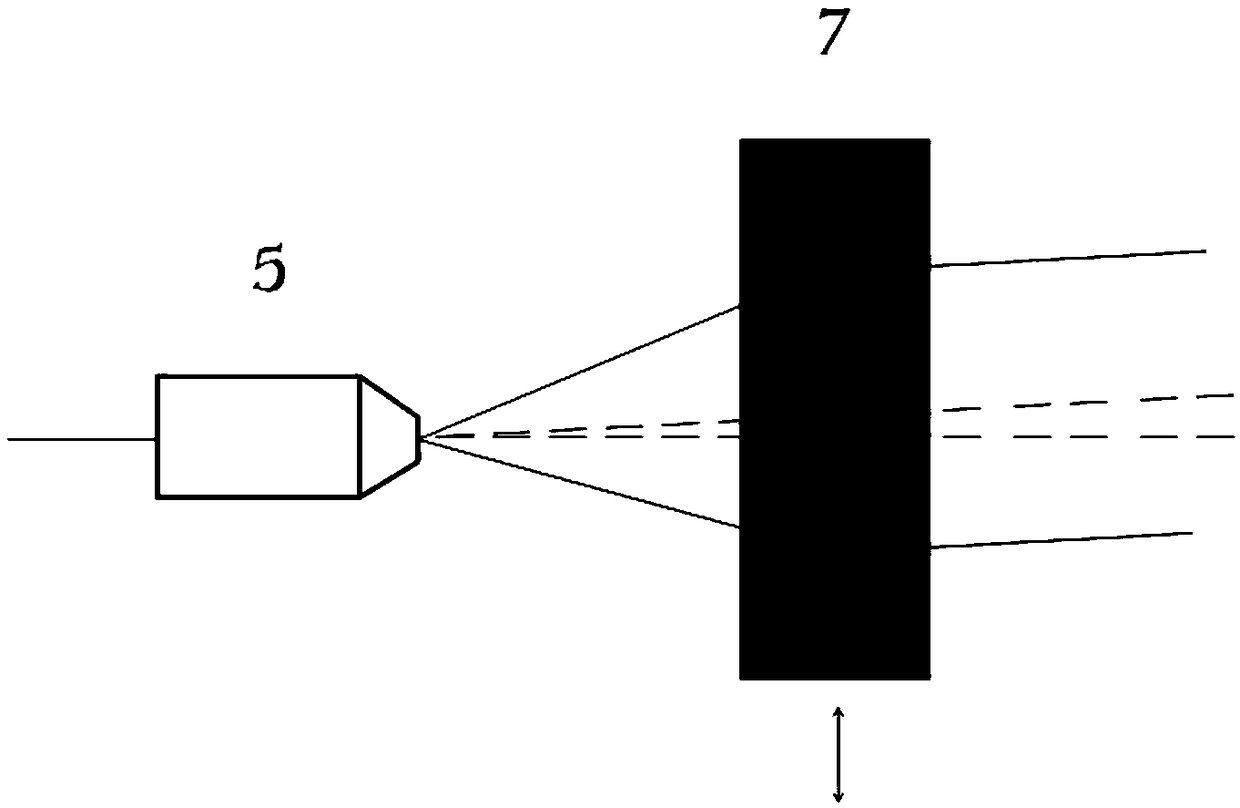

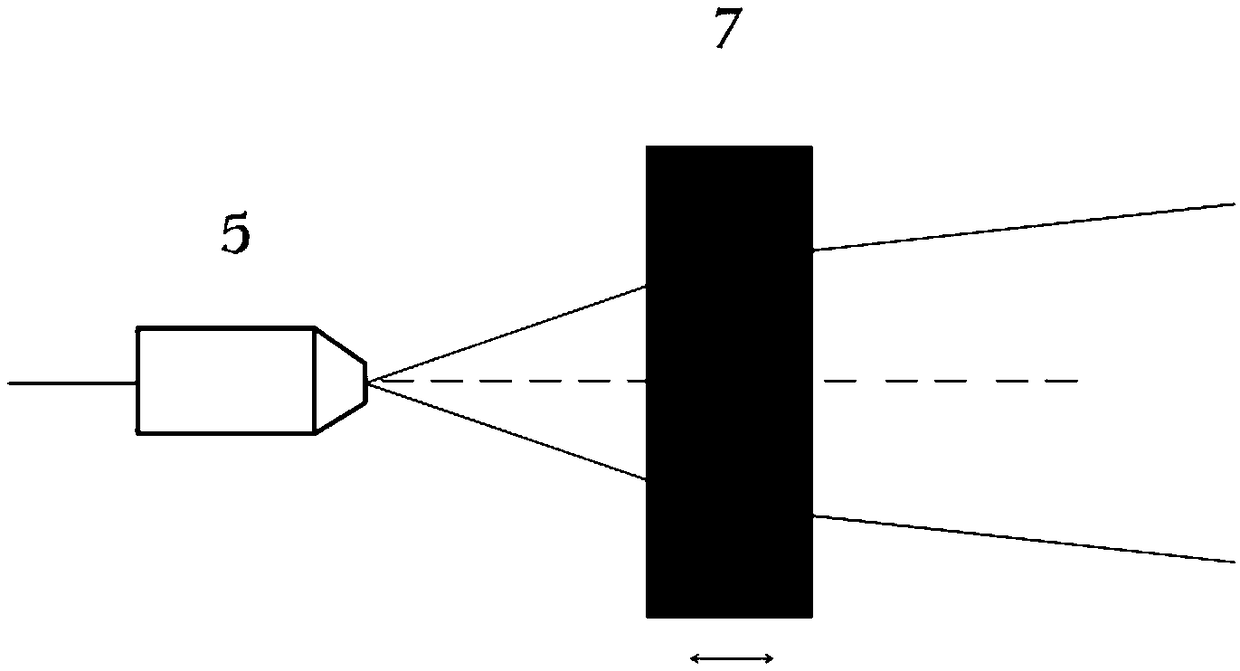

[0048] In this embodiment, the period of the holographic grating to be measured and adjusted is 833.333 nm (1200 lines / mm), and the included angle of the holographic beam is 30.6864 degrees. The holographic light source used is a helium-cadmium laser (Kimmon, model IK4171I-G) with a wavelength of 441 nm and a laser output power of 180 mW. The incident light is divided into two beams with an energy ratio of 1:1 by the half-mirror, and then irradiated on two silver-coated mirrors, and the angle of the mirrors is adjusted to make the beams intersect symmetrically, and the included angle is close to 30.7 degrees. The filtering objective lens and the collimating lens device are symmetrically placed in the two beams, and the outgoin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap