Mobile phone coating film prepared from high-entropy liquid metal alloy target

A liquid alloy, mobile phone technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of poor weather resistance, scratch resistance, and greatly increased manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

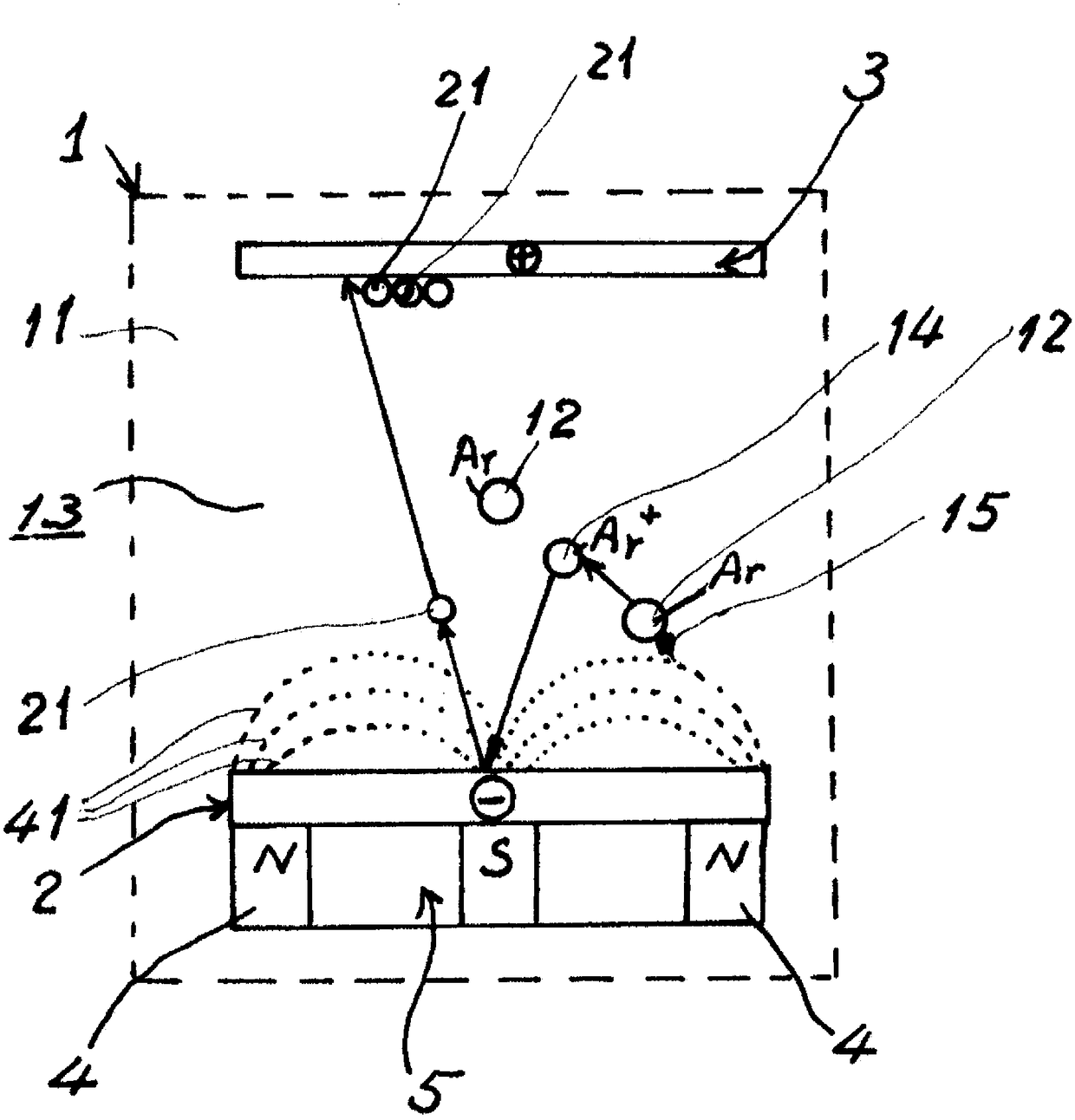

Image

Examples

Embodiment 1

[0027] Example 1. Cr c Fe e Mo g Ni h C r B q Si t

[0028] Among them, the atomic % (atomic%) of c, e, g, h, r, q, and t are:

[0029] c=15~50%; e=20~50%; g=10~30%; h=0~50%; r=5~20%; q=4~20%;

[0030] t=1~10%.

Embodiment 2

[0031] Example 2.Co b Cr c Fe e Mo g Ni h Ti i W j C r B q Si t

[0032] Among them, the atomic % (atomic%) of b, c, e, g, h, i, j, r, q, and t are:

[0033] b=5~30%; c=10~35%; e=10~35%; g=0~30%; h=10~35%; i=5~35%;

[0034] j=0~30%; r=0~20%; q=0~20%; t=1~10%.

Embodiment 3

[0035] Example 3. Cr c Fe e Mo g Ni h C r P s B q

[0036] Among them, the atomic % (atomic%) of c, e, g, h, r, s, and q are:

[0037] c=5~30%; e=10~30%; g=5~20%; h=10~50%; r=3~15%; s=5~20%;

[0038] q=3~10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com