Automatic micro-arc oxidation system and method

An oxidation system, micro-arc oxidation technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of large gantry cranes, hidden dangers of production safety, large space, etc., and achieve good processing speed and stability , The effect of reducing the waiting time of workpieces and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

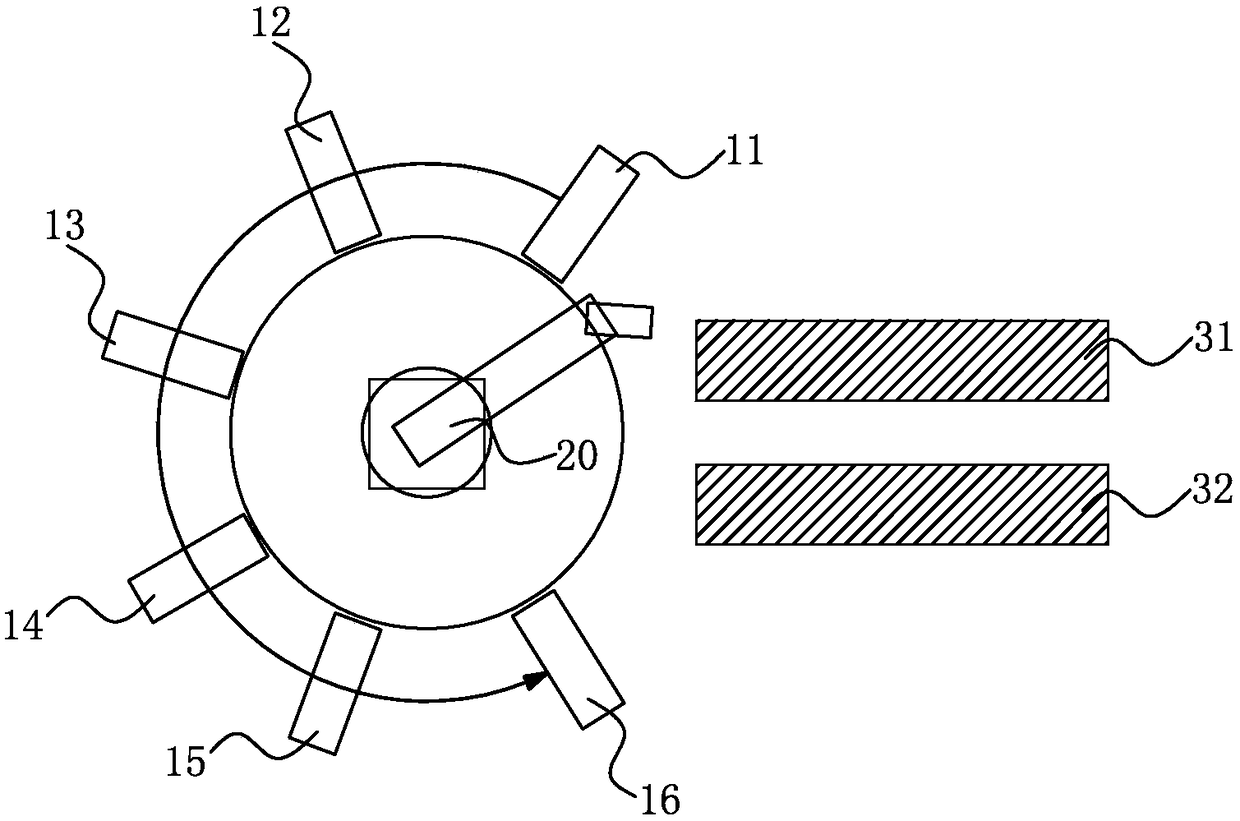

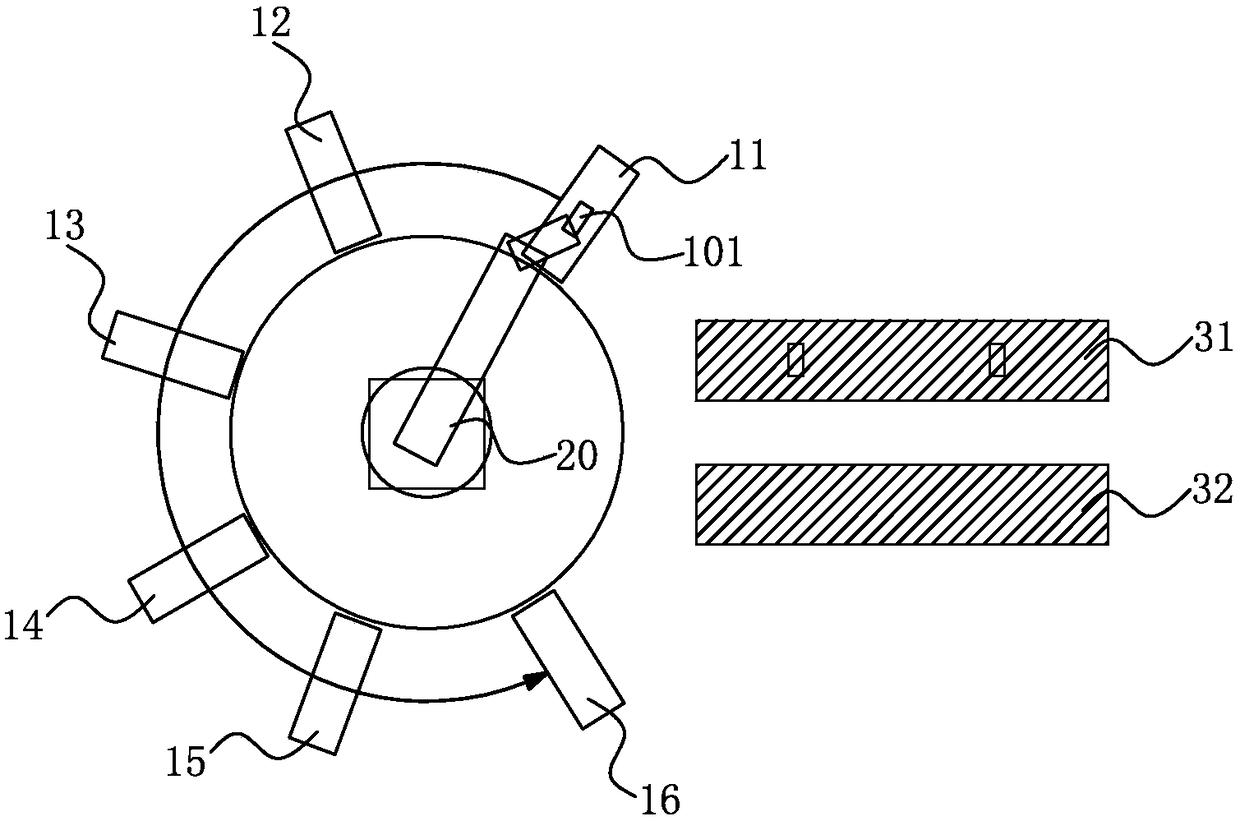

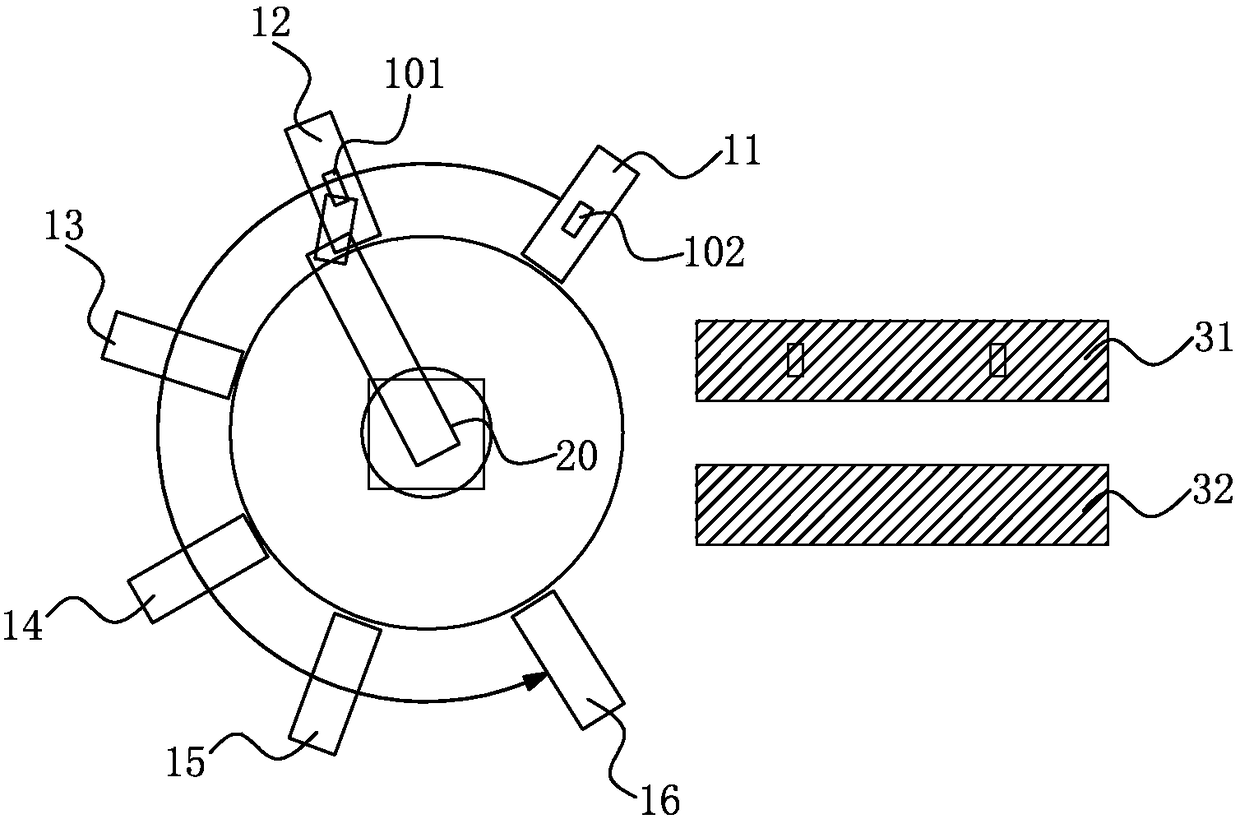

[0024] see figure 1 as shown, figure 1 It is a schematic diagram of the automatic micro-arc oxidation system of the present invention.

[0025] Each step in the required micro-arc oxidation process is set to be carried out in a corresponding separate tank, and the steps of degreasing, first water washing, micro-arc oxidation, second water washing, third water washing, and hole sealing are used The tanks correspond to the first tank 11, the second tank 12, the third tank 13, the fourth tank 14, the fifth tank 15, and the sixth tank 16; , a manipulator 20 is set at the center, and the manipulator 20 can extend into any of the surrounding grooves; beside the manipulator 20, a conveyor belt is also provided. A control computer (not shown in the figure) is connected to the manipulator for signals, and gives action instructions to the manipulator according to a preset program.

[0026] Preferably, the manipulator 20 is a six-axis manipulator, which can flexibly rotate at multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com