Differential probe and non-contact voltage measuring device

A voltage measurement, non-contact technology, applied in the direction of measuring devices, only measuring voltage, measuring electrical variables, etc., can solve the problems of inability to obtain voltage values, high cost of differential probes, and large equipment volume, which is conducive to mass production. Application, good practicability, effect of small device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

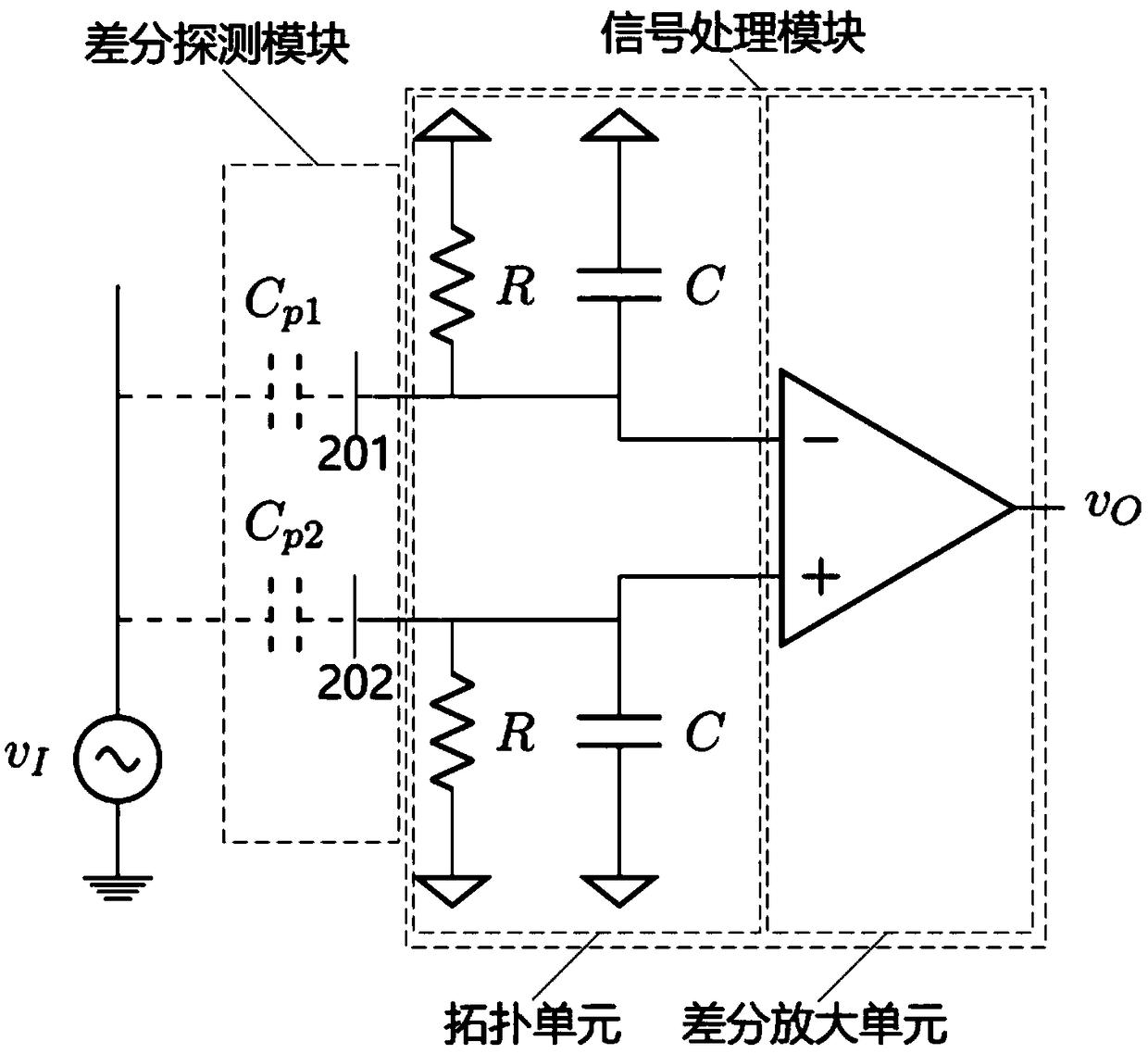

[0043] figure 1 A structural diagram of a non-contact voltage measurement system according to an embodiment of the present invention is shown. The non-contact voltage measurement system in the embodiment of the present invention includes a differential detection module, a signal processing module and a data processing module, and the differential detection module, the signal processing module and the data processing module are connected in sequence.

[0044] Among them, the differential detection module of the embodiment of the present invention is used to form two unequal first parasitic capacitances C with the line to be tested P1 and a second parasitic capacitance C P2 , and based on the first parasitic capacitance C P1 and a second parasitic capacitance C P2 Obtain the input voltage V of the line under test i (s).

[0045] Generally, a capacitance can always be formed between any two insulating metal objects, especially when the insulation distance is small, the capac...

Embodiment 2

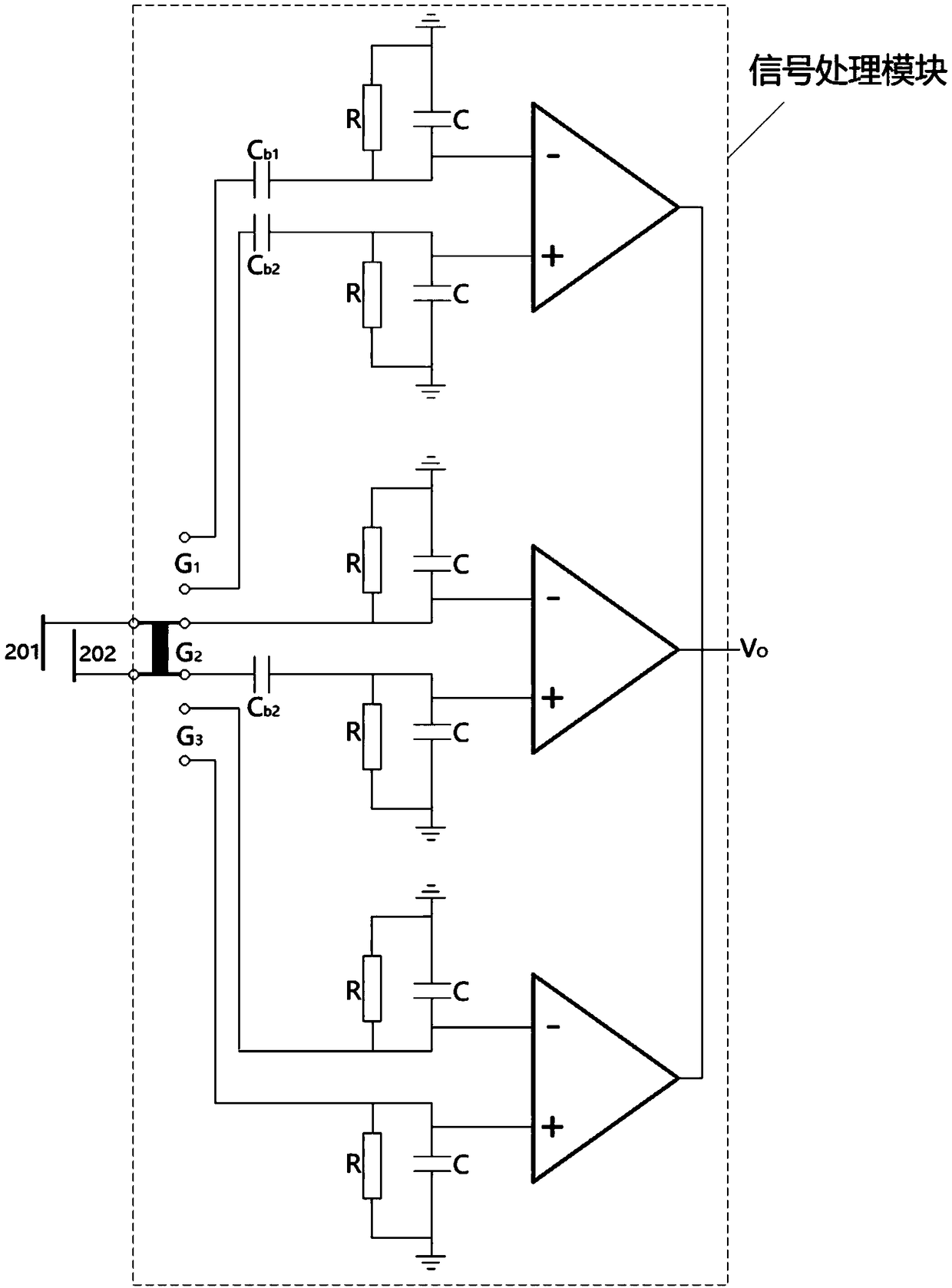

[0066] image 3 A structural diagram of a signal processing module according to an embodiment of the present invention is shown. Generally, a signal processing module includes a plurality of topology units and a topology switching unit.

[0067] The topology switching unit is respectively connected to the differential detection module and the plurality of topology units, and is used to switch the connection state between the plurality of topology units and the differential detection module;

[0068] The plurality of topological units have different transfer functions respectively, and are used to process the input voltage V of the line to be tested. i (s), generating the corresponding output value.

[0069] An embodiment of the present invention provides an implementation of a signal processing module. The signal processing module in the embodiment of the present invention includes a topology switching unit and three topology units. switch), the three topological units are G...

Embodiment 3

[0083] On the basis of the second embodiment, in order to simplify the module structure, it can be known from the signal processing mode of the signal processing module that only one differential amplification unit is working at the same time. Therefore, G 1 , G 2 , G 3 A differential amplifier unit can be shared to save cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com