A method for intelligently classify and managing that quality of tubular yarn and a device for realize the same

A technology of classification management and bobbins, applied in the direction of collaborative operation devices, image analysis, image data processing, etc., can solve the problems of low efficiency, waste of manpower and material resources, and high error rate, to improve processing speed, achieve continuity, improve Processing accuracy is the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

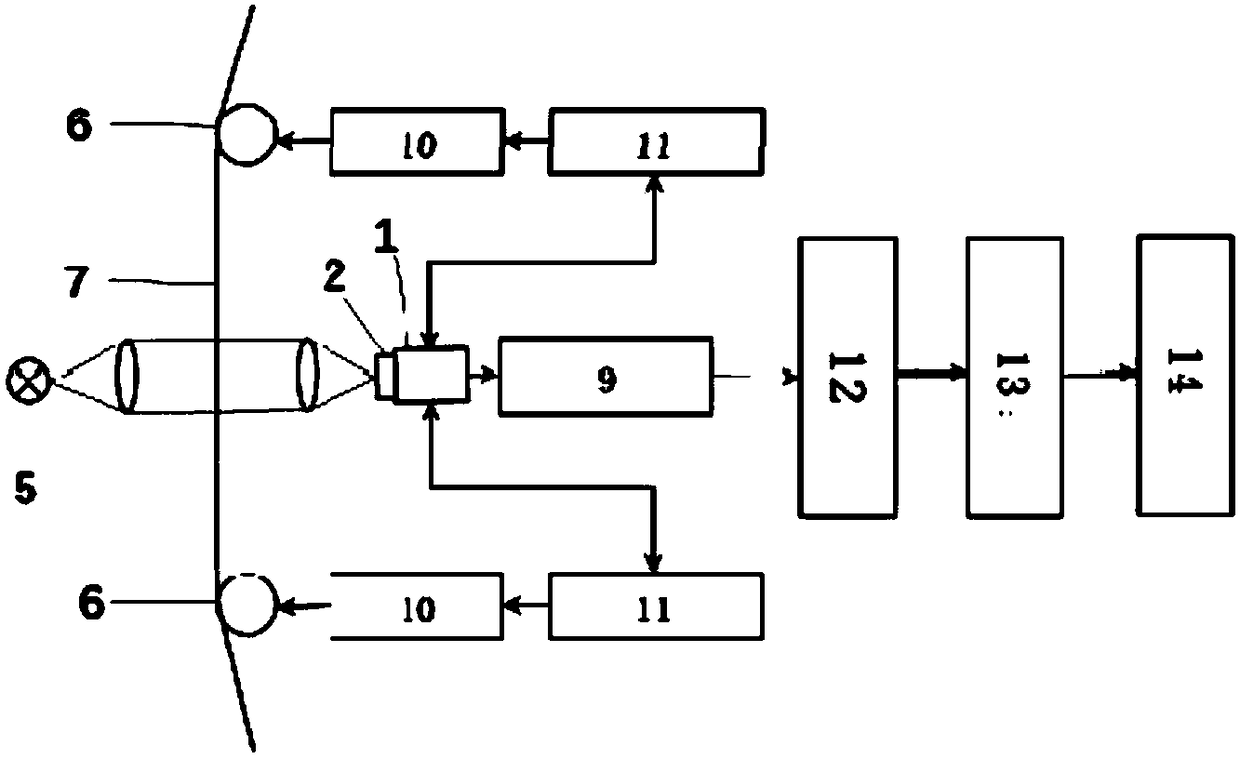

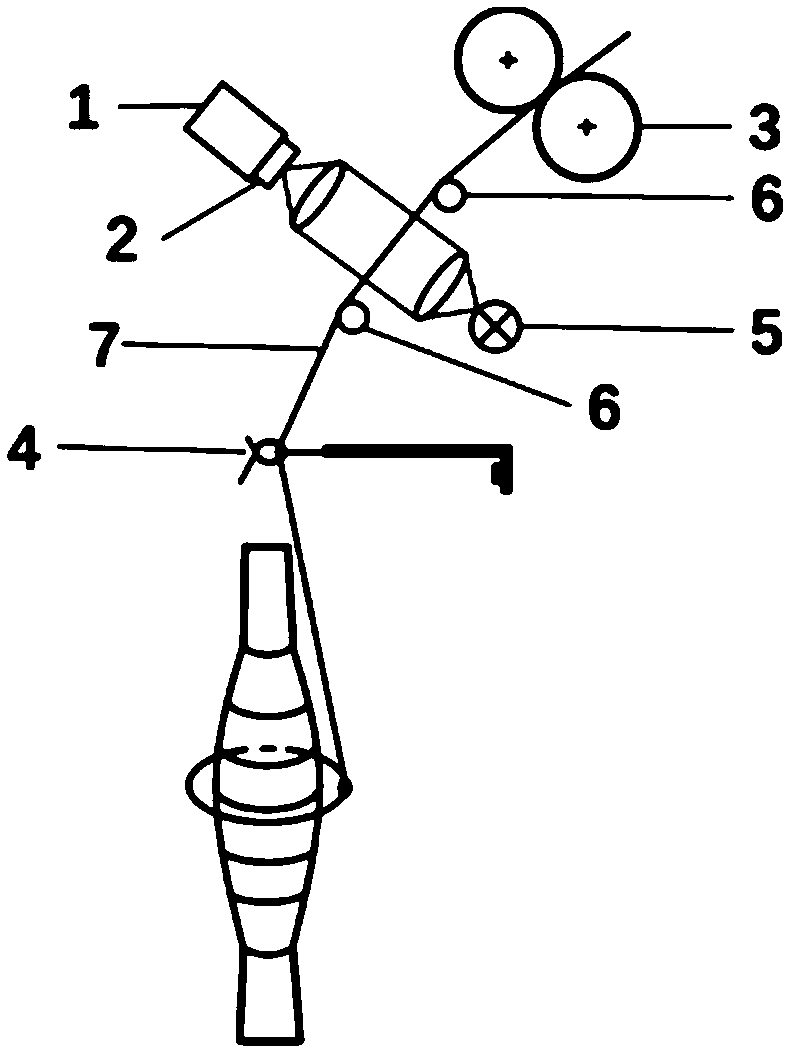

[0063] A device for intelligent classification management of bobbin quality, such as figure 1 As shown, it includes a signal acquisition device, an RFID system 13 for determining the grade information of the bobbin and storing it in an electronic tag on the bobbin, and a track sorter 14 .

[0064] The signal acquisition device is mainly composed of an image collector, a light source 5, a signal processor 11, a driving device 10, a yarn instantaneous stabilization device, an analog / digital converter 9 and an image processor, and the image collector, a signal processor 11, and a driving device 10 It is sequentially connected with the yarn instantaneous stabilizing device, the image collector, the analog / digital converter 9 and the image processor are sequentially connected, and the image processor is connected with the RFID system 13 .

[0065] The image collector is used to collect images of the yarn 6 and send signals to the signal processor 11, the light source 5 is used to i...

Embodiment 2

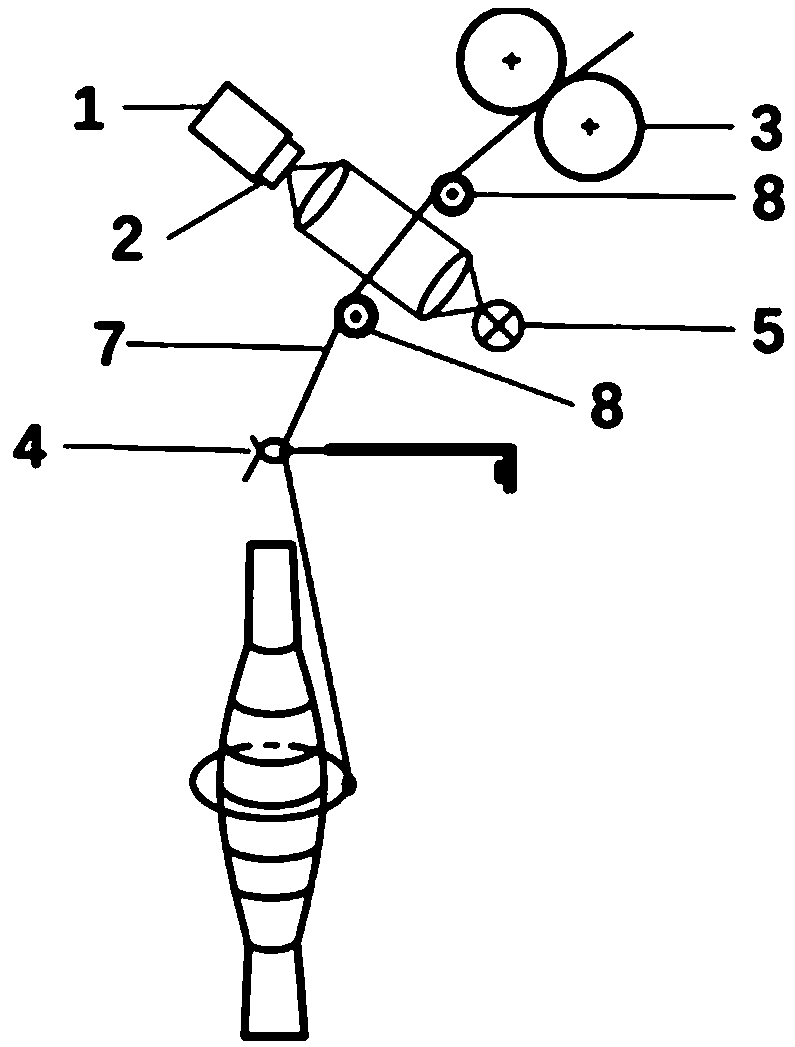

[0084] A device for intelligent classification and management of bobbin quality, the specific structure is basically the same as that of Embodiment 1, the difference is that the instant yarn stabilization device is two round wheels 8 located on the same plane, such as image 3 As shown, the circumferential surface of the round wheel 8 is provided with a right-angle groove, and the inner surface of the groove is smooth.

[0085] Using the above-mentioned device to carry out the method for intelligent classification management of bobbin quality, the specific steps are basically the same as in Example 1, the difference is that in step (1), the instantaneous stable state is formed by simultaneous contact between the yarn and two curved surfaces, and the yarn after contact The movement path changes from a straight line to a broken line. The maximum distance between the broken line running path of the yarn and the straight line running path is 1mm; The minimum distance between the n...

Embodiment 3

[0087] A device for intelligent classification and management of bobbin quality, the specific structure is basically the same as that of Embodiment 1, the difference is that the instantaneous yarn stabilization device is a long rod, such as Figure 4 As shown, the long rod is a cylindrical rod or a rotating body whose generatrix is a V-shaped broken line or a U-shaped curve. When the long rod is a cylinder, the friction coefficient of the long rod surface along the axial direction is greater than that along the tangential direction. In the present invention The shape of the long rod is not limited to this, it can be a geometry I whose cross-sectional area remains constant, it can also be a geometry II whose cross-sectional area gradually decreases from both ends to the middle, or it can be one of geometry I and geometry II. A combination of the above components, the cross-section of the geometric body I is a circle, ellipse or a shape surrounded by irregular closed curves, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com