Automatic sling for guide pillar of reactor core in pressurized water reactor(PWR) nuclear power plant

A pressurized water reactor nuclear power plant and guide column technology, applied in the field of automatic spreader for the core guide column of the pressurized water reactor nuclear power plant, can solve problems such as climbing long ladders, and achieve the effects of reliable function, ingenious and simple structural design, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

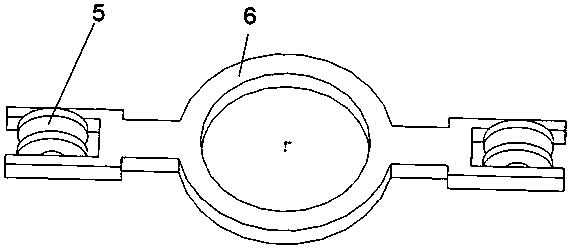

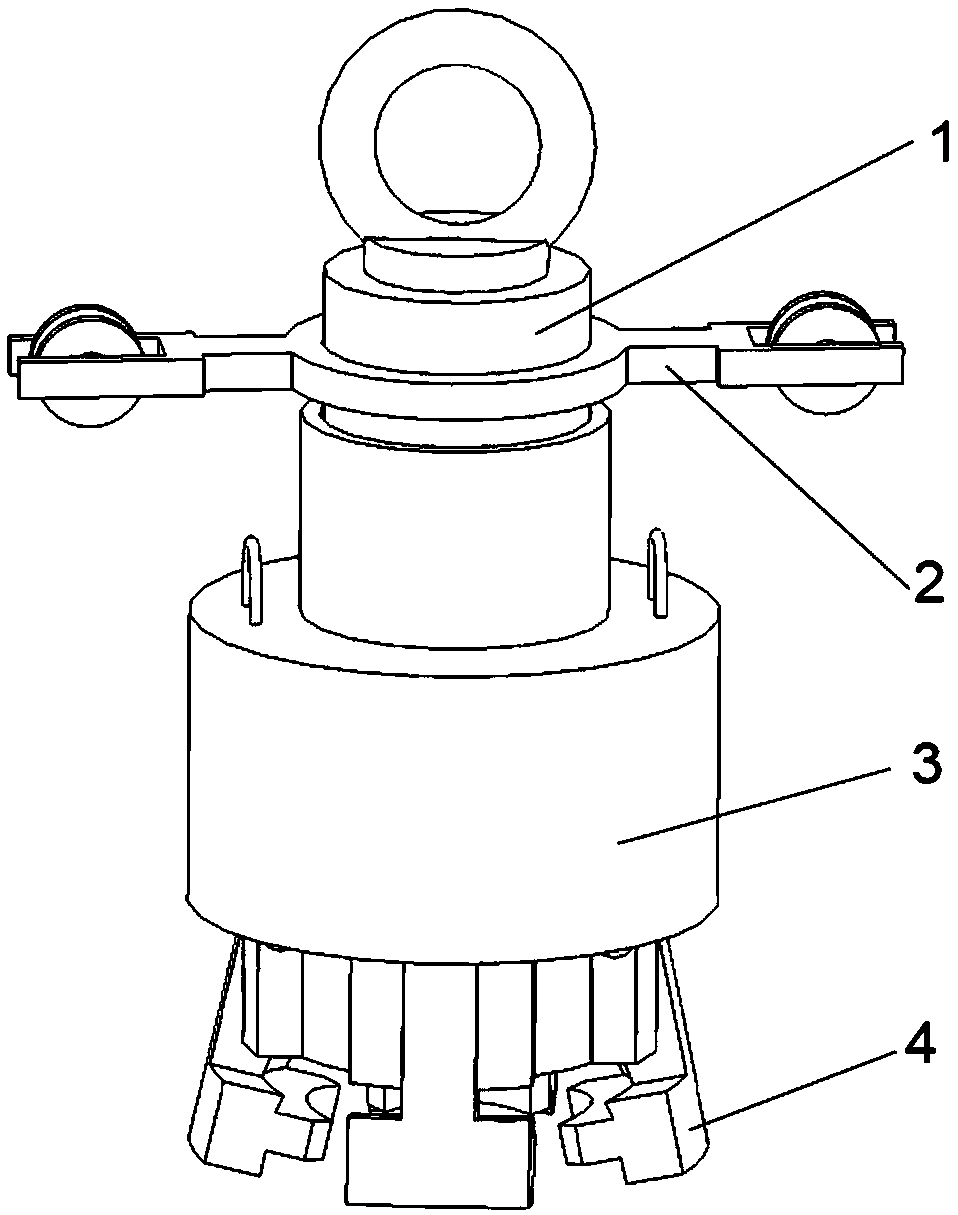

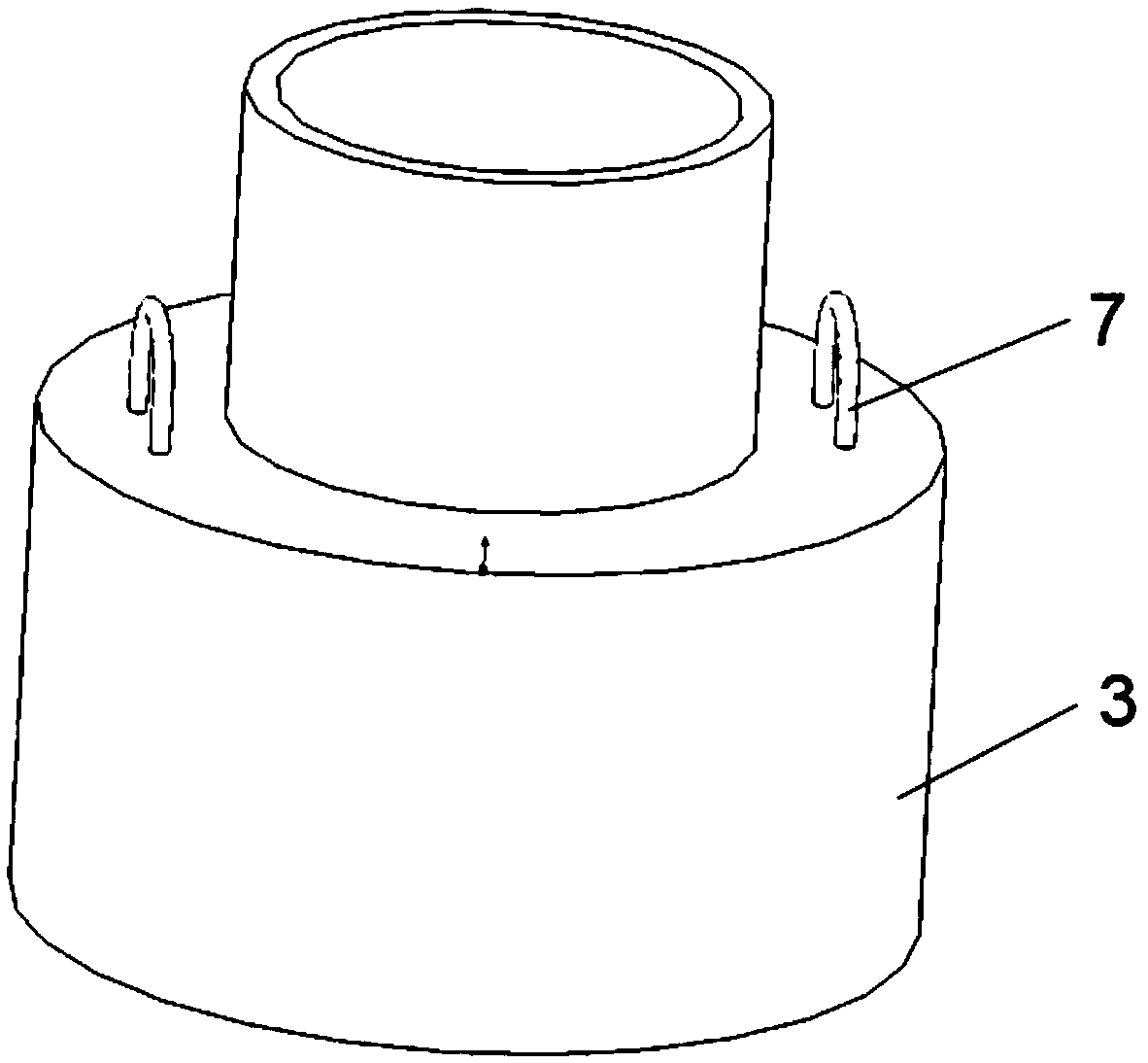

[0023] like Figure 1~5 As shown, an automatic spreader for the core guide column of a pressurized water reactor nuclear power plant, including a spreader center rod 1, a fixed pulley lifting mechanism 2, a drive sleeve 3 and claws 4, wherein the spreader center rod 1 includes a stepped cylinder Structure claw support 8 and the suspension ring 9 fixedly installed on the upper top of the claw support 8, the upper part of the claw support 8 is a cylindrical structure with a slightly smaller diameter, and the side wall of the lower part of the claw support 8 is evenly distributed. A draw-in slot, the width of the draw-in slot is matched with the upper part of the claw 4, and a pin hole is arranged on each draw-in slot, which matches with the pin hole in the upper part of the claw 4, and the claw can be connected by the pin shaft. 4 Installed in the slot of the claw support 8; the drive sleeve 3 is set on the center rod 1 of the spreader, wherein the drive sleeve 3 is a stepped cy...

Embodiment 2

[0026] like Figure 1~5 As shown, an automatic spreader for the core guide column of a pressurized water reactor nuclear power plant, including a spreader center rod 1, a fixed pulley lifting mechanism 2, a drive sleeve 3 and claws 4, wherein the spreader center rod 1 includes a stepped cylinder Structure The claw support 8 and the suspension ring 9 fixedly installed on the upper top of the claw support 8, the upper part of the claw support 8 is a cylindrical structure with a slightly smaller diameter, and the side walls of the lower part of the claw support 8 are evenly distributed with 4 A draw-in slot, the width of the draw-in slot is matched with the upper part of the claw 4, and a pin hole is arranged on each draw-in slot, which matches with the pin hole in the upper part of the claw 4, and the claw can be connected by the pin shaft. 4 Installed in the slot of the claw support 8; the drive sleeve 3 is set on the center rod 1 of the spreader, wherein the drive sleeve 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com