Reheating energy-saving tea leaf roller fixation machine

A technology of drum-fixing machine and tea, applied in the direction of tea treatment before extraction, can solve the problems of insufficient utilization of heat, affecting the quality of tea leaves, black spots of tea leaves, etc., to reduce heat loss, discharge water vapor in time, and prevent The effect of black dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

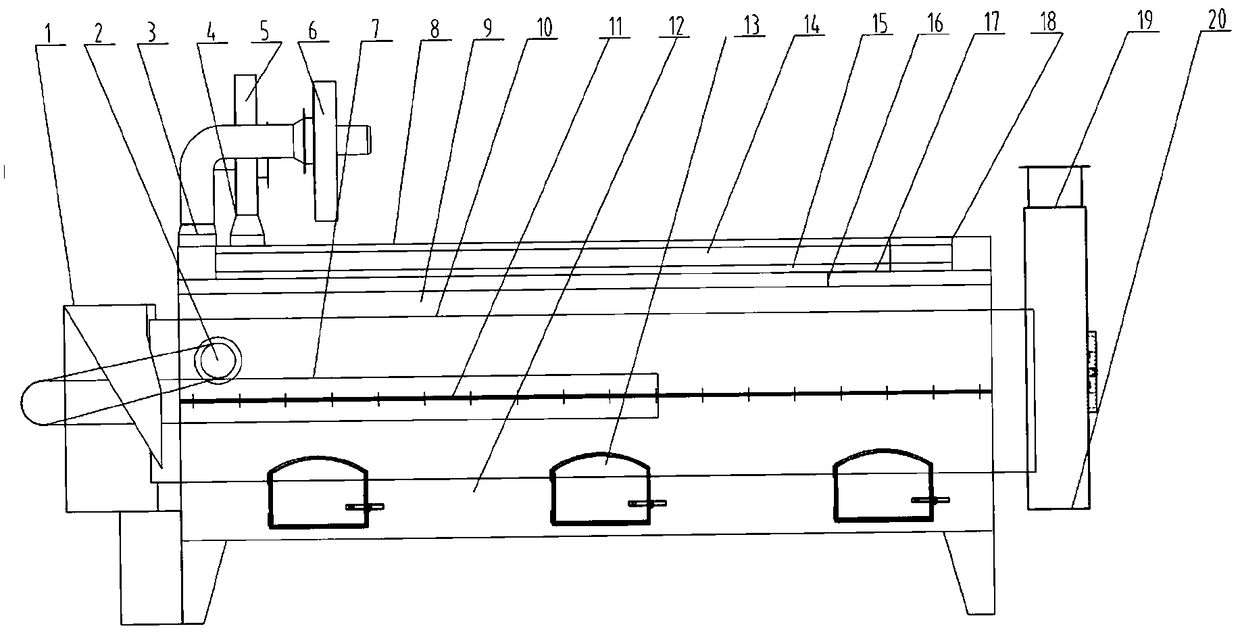

[0021] Such as figure 1 , The embodiment of the present invention provides a reheating energy-saving tea drum curing machine, comprising an upper furnace body 9, a lower furnace body 12, a drum 10 and a shell 8, wherein the upper furnace body 9 and the lower furnace body 12 are connected by a flange 11. A cylindrical furnace is formed. The drum 10 is located inside the cylindrical furnace and is supported by rollers. It can roll in the furnace under the drive of driving force. The outer shell 8 is located on the upper furnace body 9. Play the role of dustproof and prevent operators from being burned.

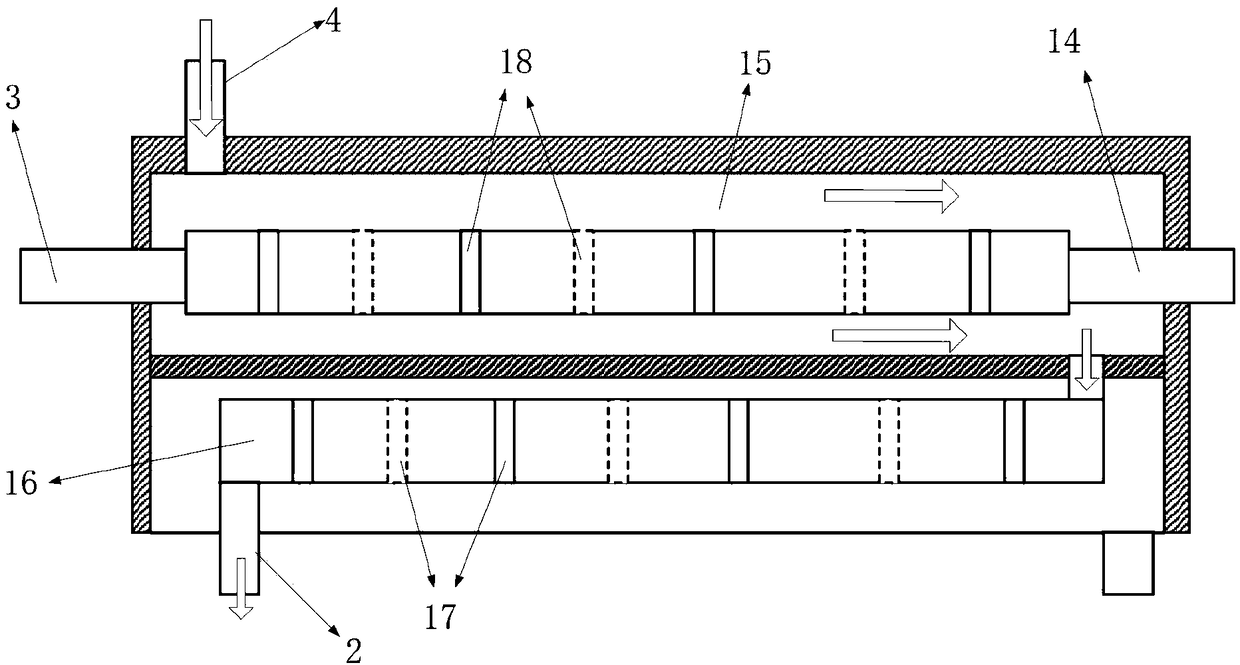

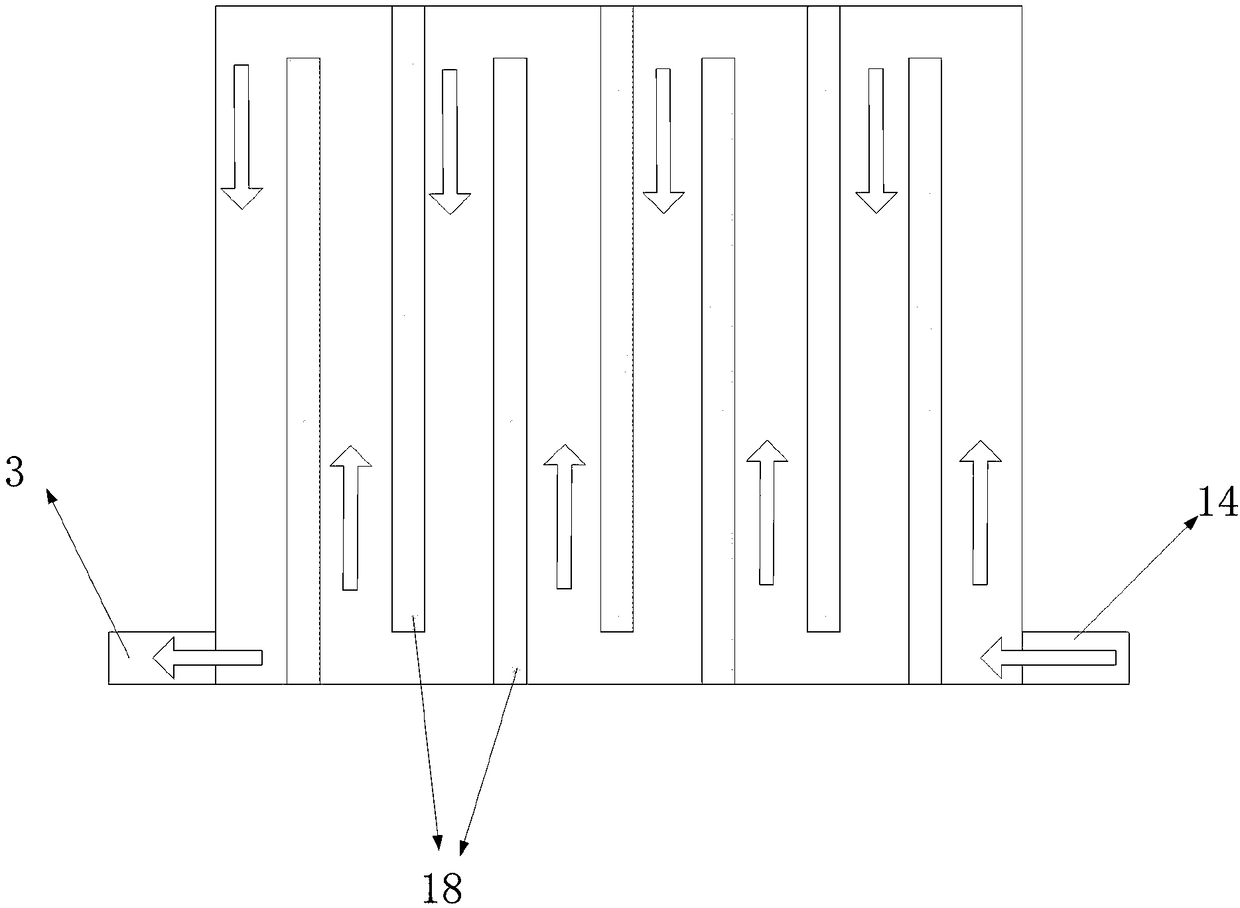

[0022] Such as figure 2 , The upper furnace body 9 includes two upper and lower layers, the upper layer is a smoke pipe interlayer 15, the smoke pipe interlayer 15, and the lower layer is provided with an air duct 16. The flue pipe 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com