Sealing means for heating non-combustion product

A heat-not-burn and sealing technology, applied in the manufacture of paper cigarettes, cigars, tobacco, etc., can solve the problems of restricting heat-not-burn cigarettes, easy loss of aroma, and difficulty in quality preservation, so as to improve smoking effect, increase ventilation efficiency, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

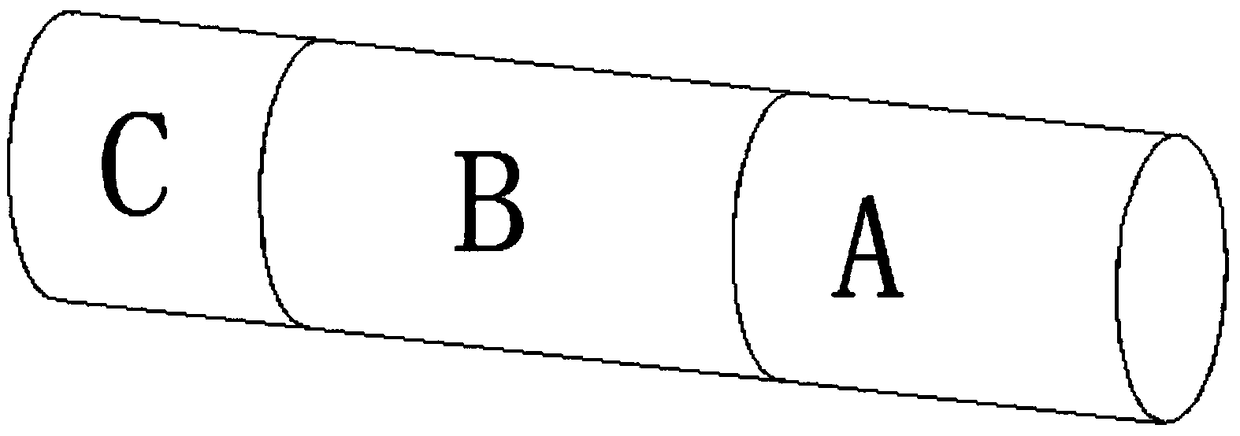

[0020] Embodiment 1, with reference to Figure 1-6 , a sealing method for heat-not-burn products, comprising the following steps: selecting a sealing material, selecting a suitable sealing material according to the shape of a heating module of a heat-not-burn smoking appliance, and performing sealing; using the sealing material will require heat-not-burn The far lip of the smoke unit is sealed or both ends are sealed to form a smoke unit. The seal is processed by sizing or calendering technology. When selecting the sealing material, special paper is preferred. Special paper includes colored paper, high temperature resistant paper, and high air permeability paper. , the air permeability of the paper is 4000-8000CU, and then use sizing and calendering or outsourcing packaging technology to seal the far lip of the smoking product, and at the same time completely cut off the excess paper on the outer edge of the smoking product. This sealing technology can achieve ventilation and a...

Embodiment 2

[0021] Embodiment 2, with reference to Figure 1-6 , a sealing method for heat-not-burn products, comprising the following steps: selecting a sealing material, selecting a suitable sealing material according to the shape of a heating module of a heat-not-burn smoking appliance, and performing sealing; using the sealing material will require heat-not-burn The far lip of the smoke unit is sealed or both ends are sealed to form a smoke unit. The seal is processed by sizing or calendering technology. When selecting the sealing material, special laser, electrostatic or mechanically perforated paper and mechanically perforated aluminum foil are preferred as raw materials. , the air permeability of the special paper is 4000-8000CU, and then use the sizing and calendering packaging technology to seal the far lip of the smoking product, and seal the two ends of the smoking section to form a single smoking unit. This sealing technology can achieve ventilation and avoid Efficacy of smoki...

Embodiment 3

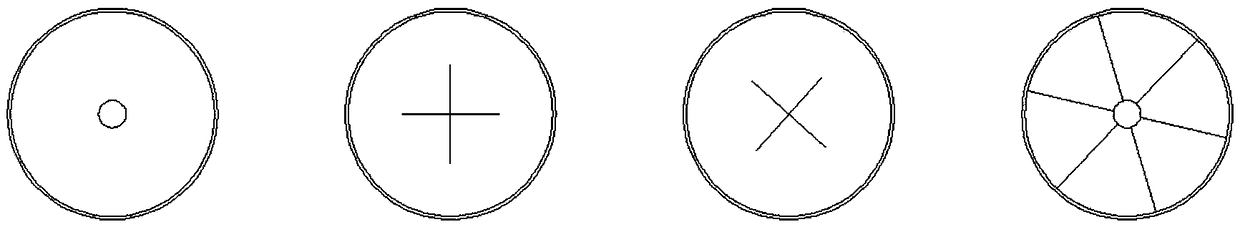

[0022] Embodiment 3, with reference to Figure 1-6 , a sealing method for heat-not-burn products, comprising the following steps: selecting a sealing material, selecting a suitable sealing material according to the shape of a heating module of a heat-not-burn smoking appliance, and performing sealing; using the sealing material will require heat-not-burn The far lip of the smoke unit is sealed or both ends are sealed to form a smoke unit. The seal is processed by sizing or calendering technology. When selecting the sealing material, silica gel and ceramic hard materials are preferred as raw materials, and the above-mentioned The material is opened, and the shape of the opening is round hole, line hole, one-shaped, cross-shaped, X-shaped, etc. The end surface structure is as follows: image 3 As shown in Fig. 1, a cap with an inner buckle slightly smaller than the inner diameter of the smoking product is added to the far lip end. This sealing technology can achieve the effects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com