Suitcase structure

A technology for bags and panels, applied in superstructure sub-assemblies, connections between superstructure sub-assemblies, building components, etc., can solve high labor input and material costs, luggage suffered from impact, low support strength, etc. problems, achieve the effect of maintaining structural integrity, improving strength and stability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

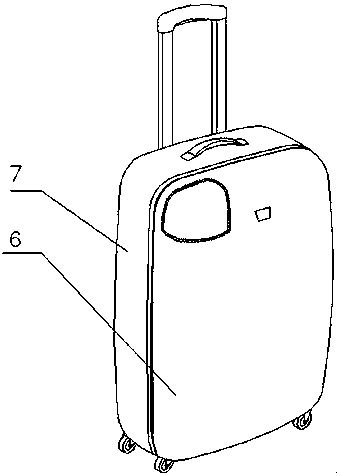

[0051] Such as Figure 1~Figure 5 Shown: a luggage case, comprising a first shell 6 and a second shell 7, wherein the first shell 6 can be separated along a separation line and connected to the second shell 7 to define a storage space; A housing 6 is made of a curved metal plate. The metal plate is pivotally connected to the second housing 7 .

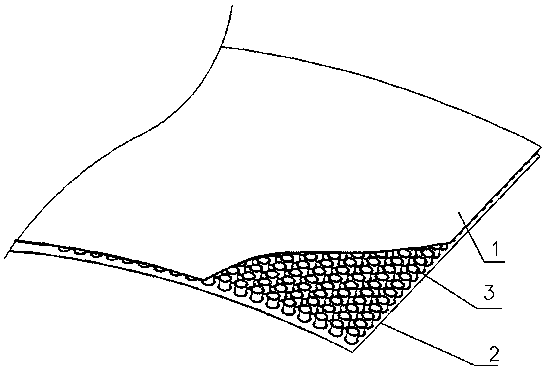

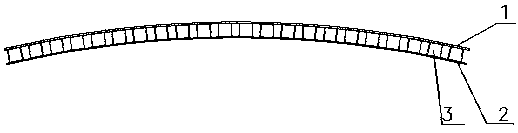

[0052] Specifically, the metal plate includes a first panel 1, a second panel 2, a plurality of hollow tubes 3 in the middle, and a brazing layer between the hollow tubes 3 and the first panel 1 and the second panel 2. The upper and lower sides of the hollow tubes 3 Each end is provided with a flanging 31, which turns out a circular structure. The flange 31 of the hollow tube 3 is connected to the first panel 1 and the second panel 2 by soldering 4 .

[0053] Both the first panel 1 and the second panel 2 are curved panels. The two ends of the hollow tube 3 are vertically connected with the contact surface of the panel. The line ty...

Embodiment 2

[0062] Such as Figure 6 Shown: The difference from Embodiment 1 is that both the first casing and the second casing are made of metal plates. Wherein, the first shell is made of a metal plate with a curved surface, and the structure of the metal plate is the same as that of the first embodiment. The second housing 7 is welded as a whole by four curved metal plates 71 . Because the second housing 7 has four corners, each corner part is a metal plate 71 with a curved surface; the metal plate 71 has a large arc, that is, a large central angle.

[0063] Frames 8 are provided on both sides between the panels, and the frame 8 is made of stainless steel, and the frame 8 is connected with the first panel 1 and the second panel 2 as a whole by brazing. The frame 8 is a semi-closed structure.

[0064] Others are with embodiment 1.

Embodiment 3

[0066] Such as Figure 7 Shown: a tool box, including a third housing 9 and a fourth housing 10, wherein the third housing 9 can be separated along a separation line and connected to the fourth housing 10 to define a storage space. Wherein the third housing 9 is made of a metal plate. The metal plate is pivotally connected to the fourth housing 10 .

[0067] The difference between this embodiment and Embodiment 1 is that the first panel and the second panel are both planar panels.

[0068] Other structures of the metal plate are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com