A medical device phantom, fixture and processing technology

A technology of medical equipment and processing technology, which is applied in the field of mold bodies, fixtures and processing technology, can solve the problems of poor control of parts manufacturing accuracy, unreliable bonding, and overall deformation, so as to reduce deformation and simplify processing procedures , Improve the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other implementations according to these drawings without creative efforts.

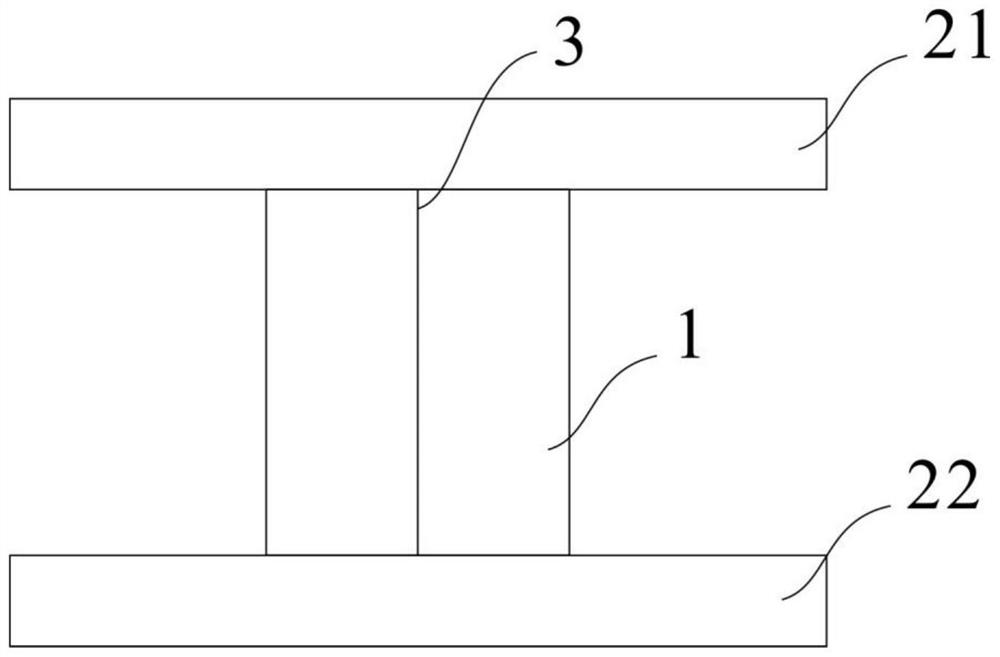

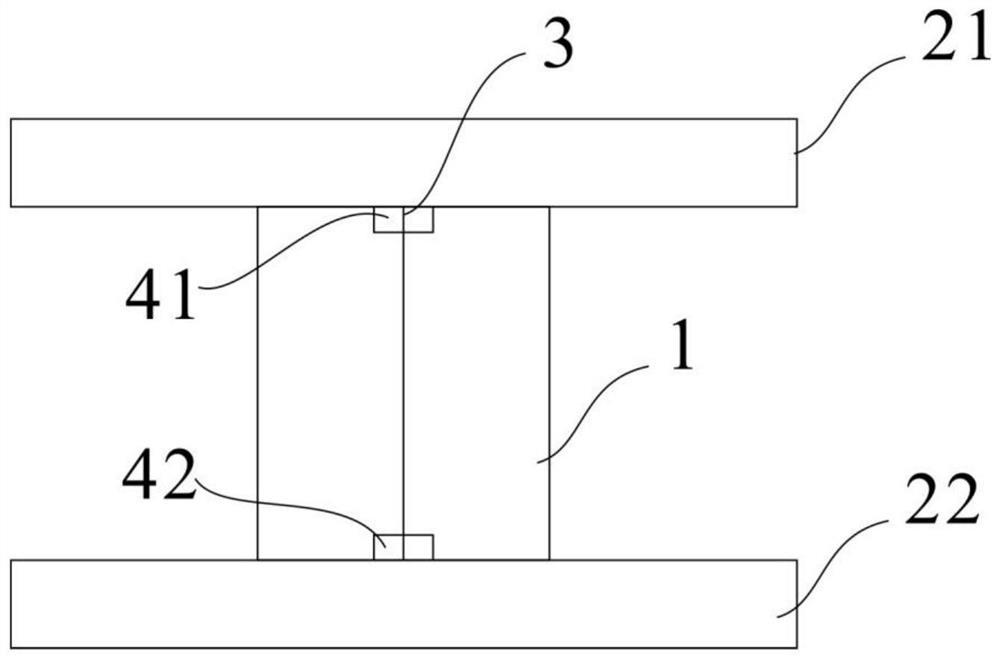

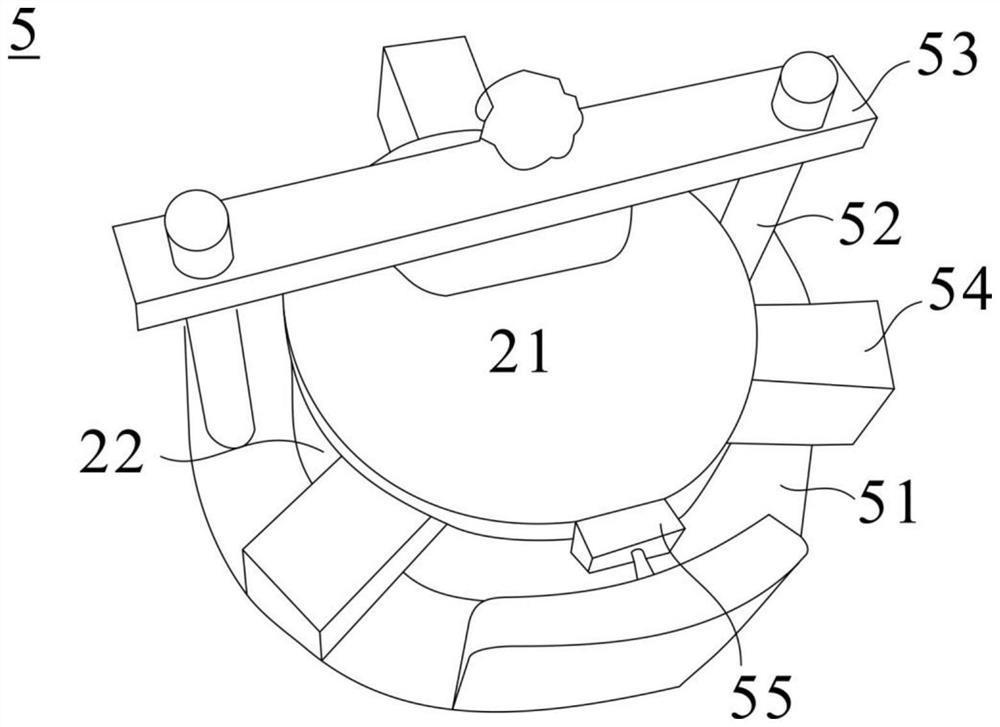

[0067] In the embodiment of the medical device phantom of the present invention, see figure 1 , 2 As shown, a medical device phantom is mainly used for correcting the accuracy of the upper moving axis of a large medical device, and the light equivalent of X-ray or nuclear magnetic resonance. The first part 21 and the second part 22; at the same time, a reference line 3 is provided in the body 1, so that the reference line 3 is perpendicular to the first part 21 and the second part 22 respectively. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com