Indium phosphide wafer sheet and substrate polishing die for epitaxy wafer sheet

A technology of wafers and indium phosphide, applied in the direction of working carriers, etc., can solve the problems of increasing research and development costs, complex structure of polishing equipment, and reducing processing efficiency, so as to improve production and research and development efficiency, high flatness, and small contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

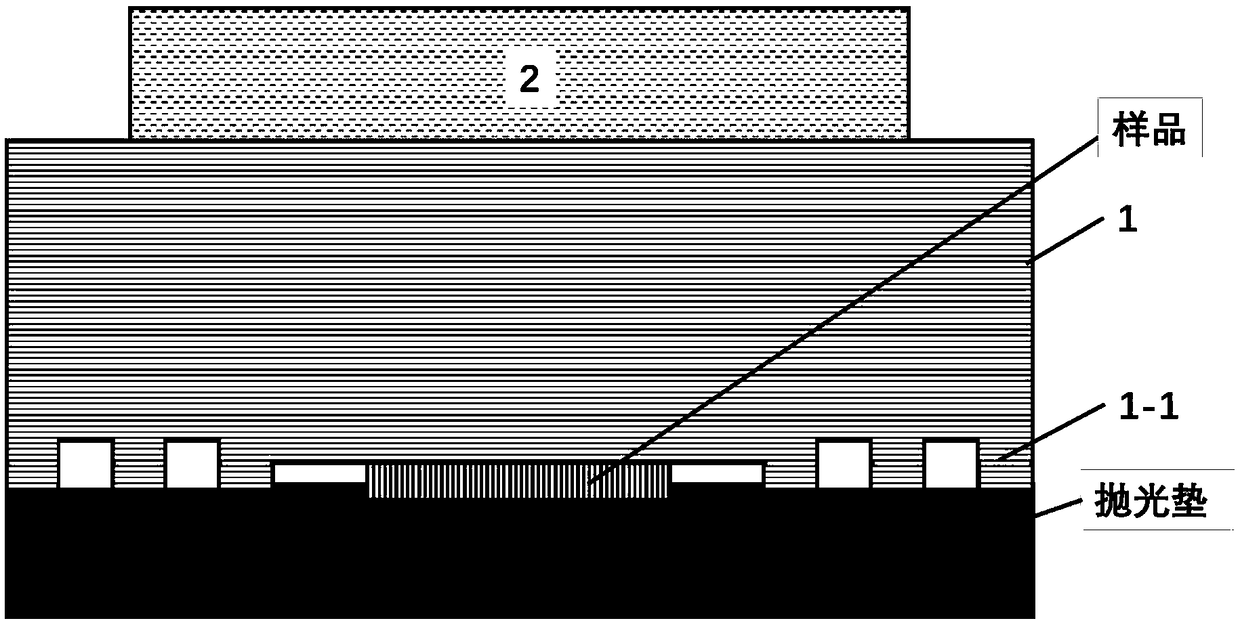

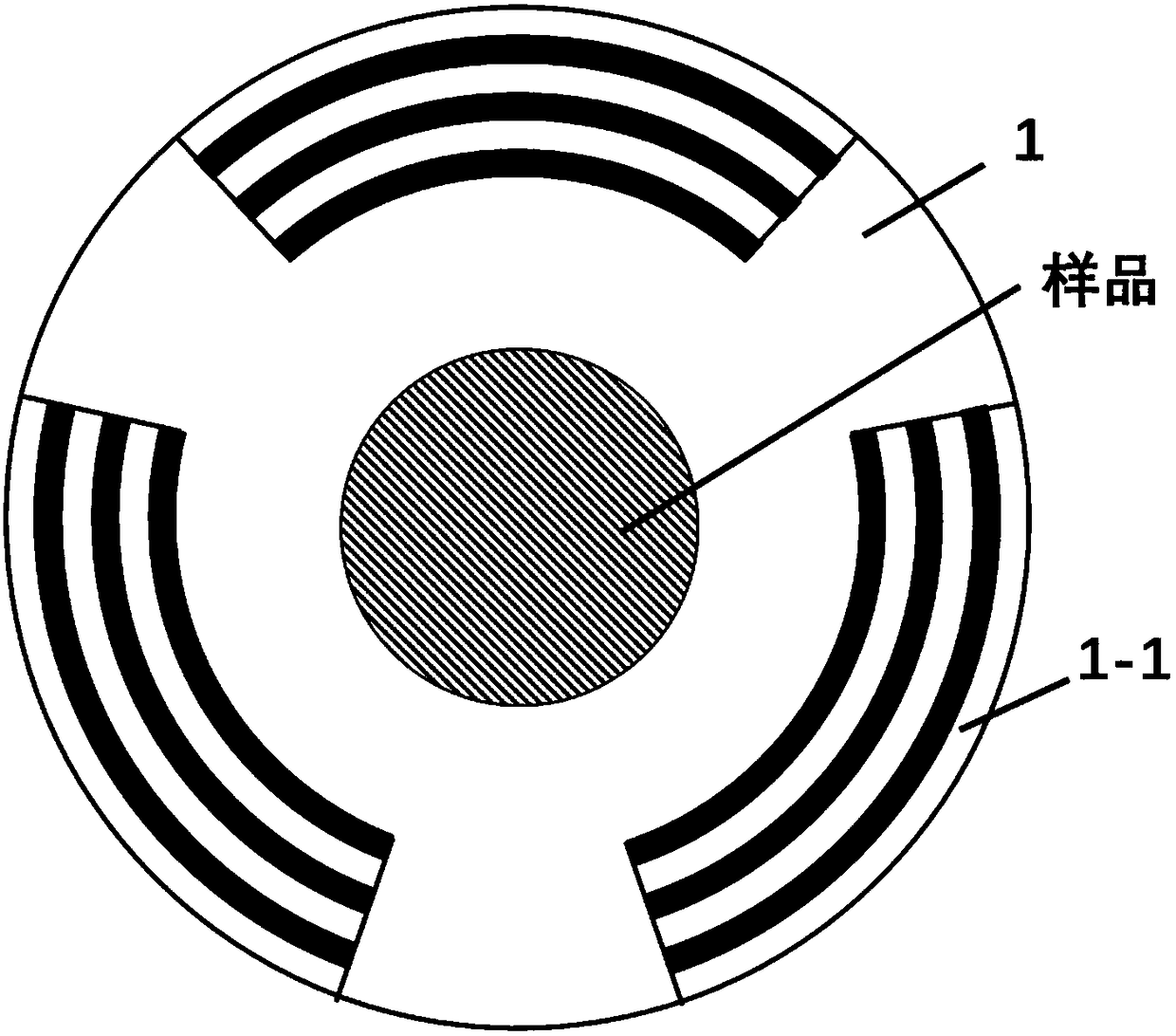

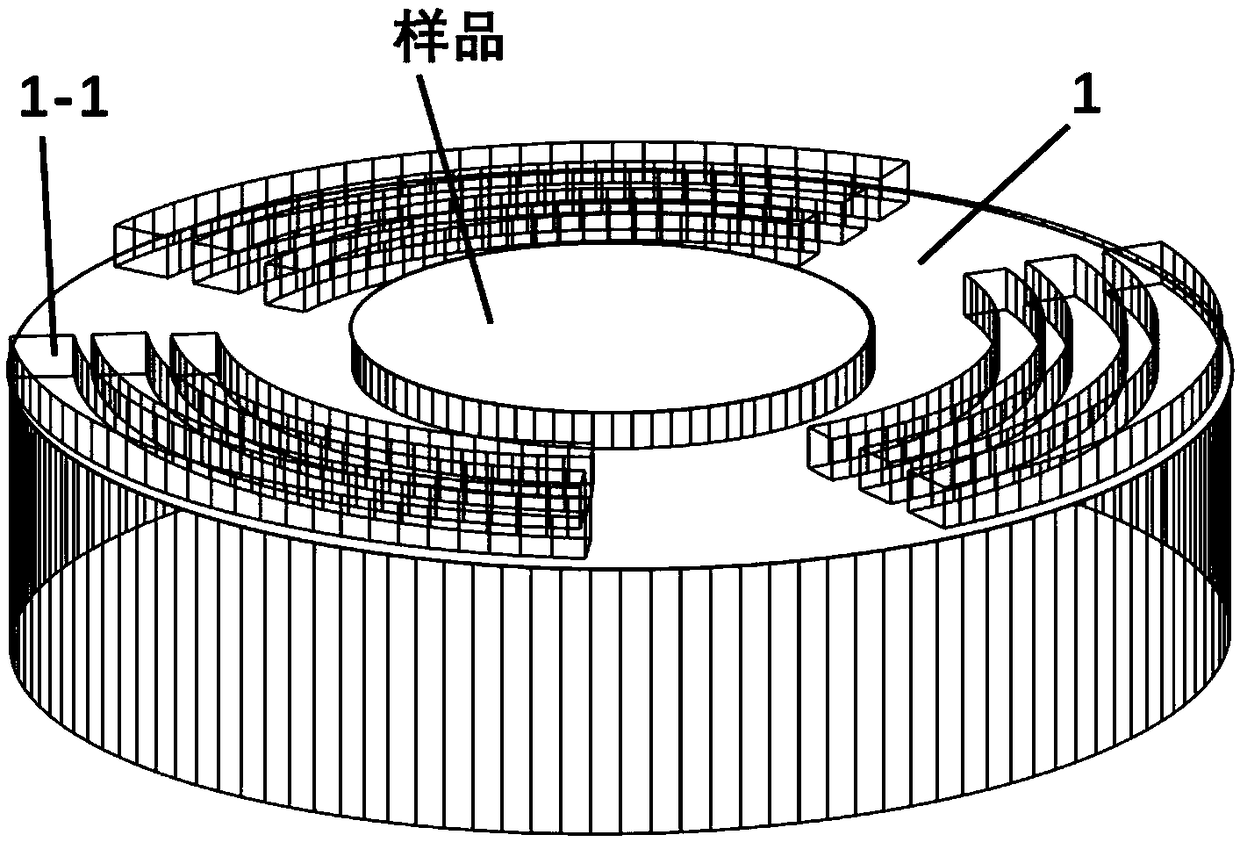

[0024] 1 The height of the ceramic channel is 300 microns, and the groove depth is 0.3 cm.

[0025] 2. Attach a 2-inch InP wafer with a thickness of 350 microns to a ceramic substrate.

[0026] 3. Fix the counterweight so that the sample bears a force of 250g / cm 2 , The speed range of the polishing disc is 80rpm. .

Embodiment 2

[0028] 1 The height of the ceramic channel is 100 microns, and the groove depth is 0.1 cm.

[0029] 2. A 150-micron thick 3-inch epitaxial indium aluminum arsenic indium phosphide wafer is attached to a ceramic substrate.

[0030] 3 Increase the counterweight to make the sample bear a force of 50g / cm 2 , The speed range of the polishing disc is 30rpm. .

Embodiment 3

[0032] 1 The height of the ceramic channel is 1000 microns, and the groove depth is 0.5 cm.

[0033] 2. Attach a 4-inch epitaxial InGaAs indium phosphide wafer with a thickness of 800 microns to a ceramic substrate.

[0034] 3 Increase the counterweight to make the sample bear a force of 500g / cm 2 , The speed range of the polishing disc is 120rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com