Power transmission vehicle anti-skid system and subway construction transporting system

A transport vehicle, anti-skid technology, applied in the direction of transportation and packaging, railway braking system, railway car body parts, etc., can solve problems such as rolling cars, achieve the effect of increasing safety, simple and reasonable structure, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

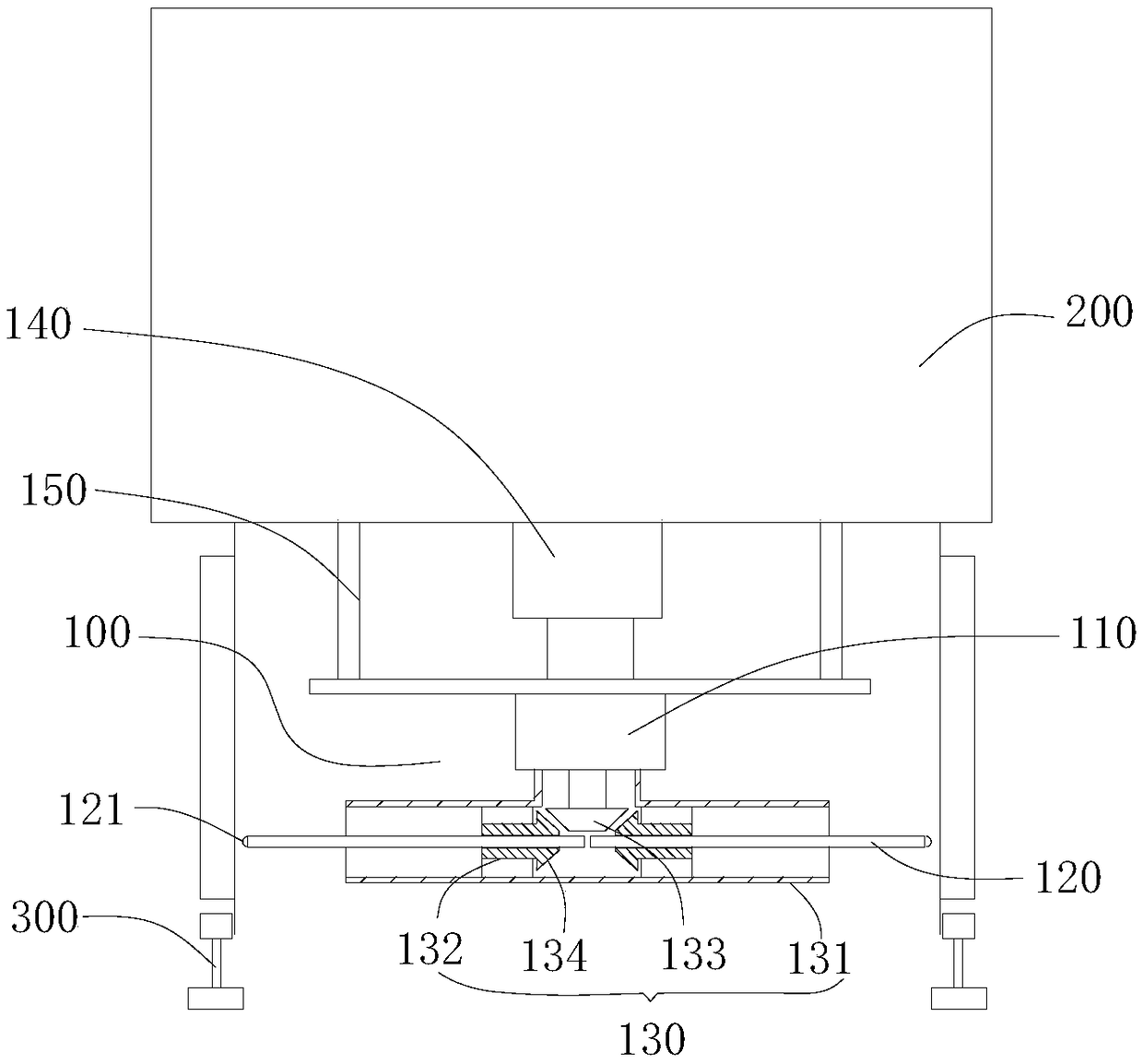

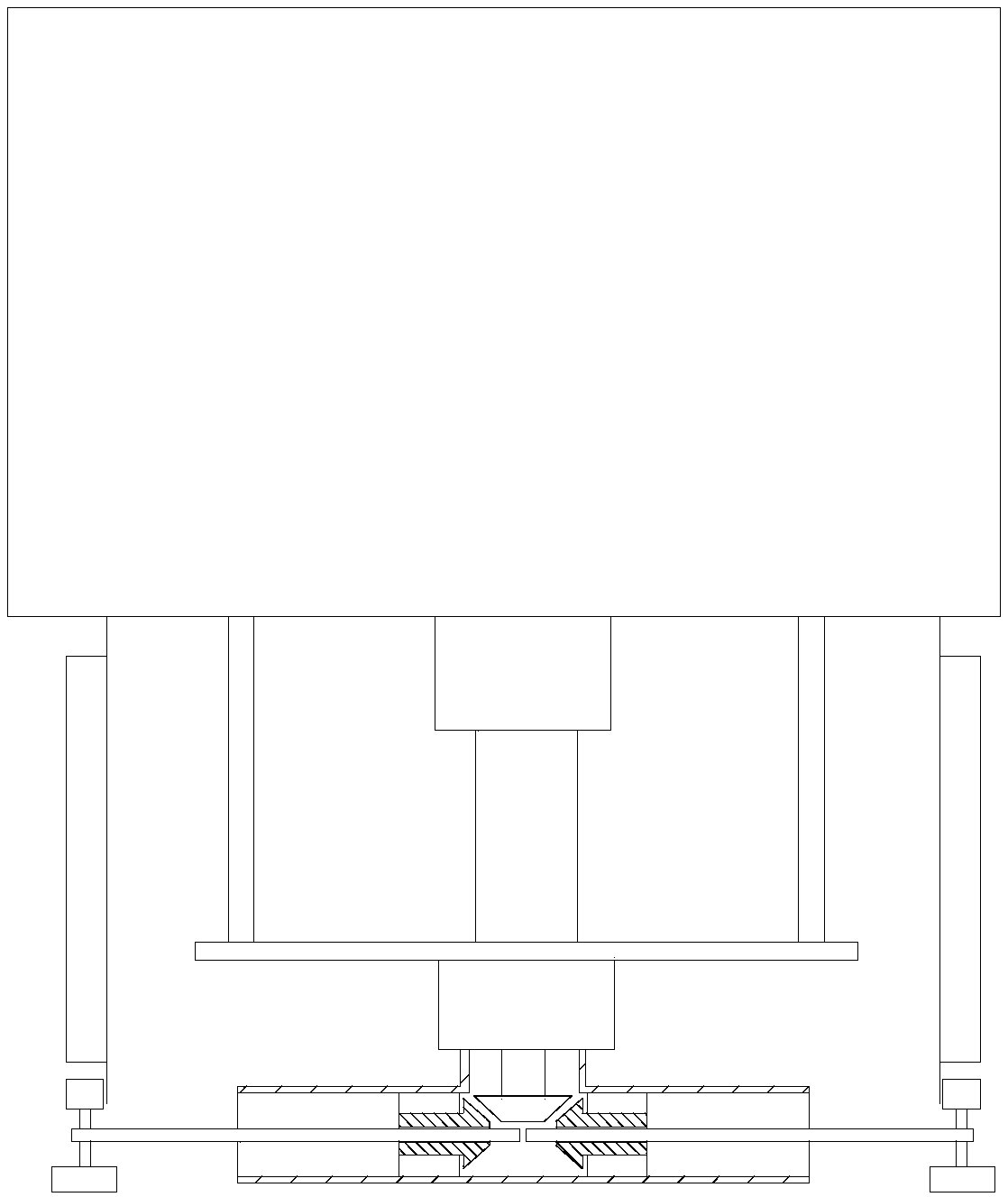

[0037] see figure 1 - Figure 5 , this embodiment provides an anti-skid system for an electric transport vehicle, which is used to install on the transport vehicle body 200 and used in conjunction with the transport rail body 300 to greatly improve the stability of the transport vehicle body 200 and improve the landslide phenomenon.

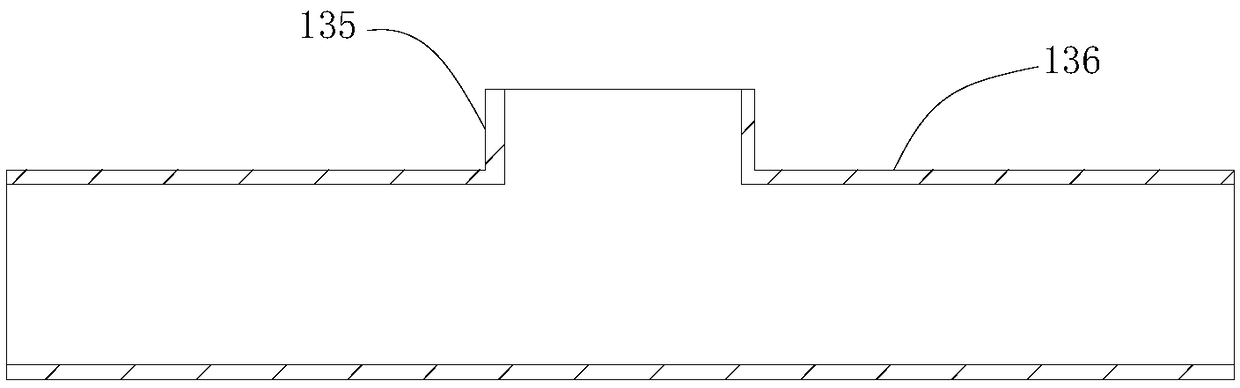

[0038] The anti-skid system of the electric transport vehicle provided in this embodiment includes a clamping mechanism 100, which is used to be installed on the transport vehicle body 200; A first clamping part 121 is provided on the top, and a second clamping part 310 is provided on the inner side of at least one section of the transportation track body. The first driving member 110 drives the connecting clamping part 120 to drive the clamping part 120 relative to the transportation rail body. 300 reciprocates, so that the first engaging portion 121 is engaged with the second engaging portion 310 or the first engaging portion 121 is separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com