Controllable nanometer graphene cutting method

A graphene and nanotechnology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of poor edge roughness and chirality control, inability to effectively control the shape of graphene, and lack of good chirality in carbon nanotubes. Control and other issues to achieve the effect of precise edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

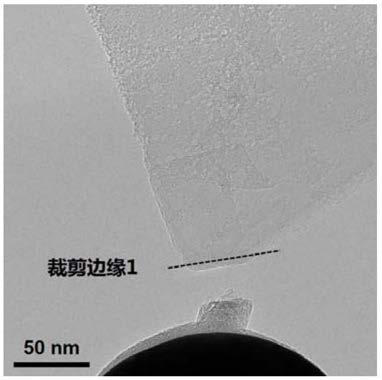

[0028] The present invention will be further described below by two embodiments and accompanying drawing, will utilize nano-knife to carry out detailed implementation method introduction to two smooth cuttings that graphene is carried out, in addition to cutting a piece of graphene of irregular shape into parallelogram The embodiment of the present invention is briefly introduced and illustrated with accompanying drawings.

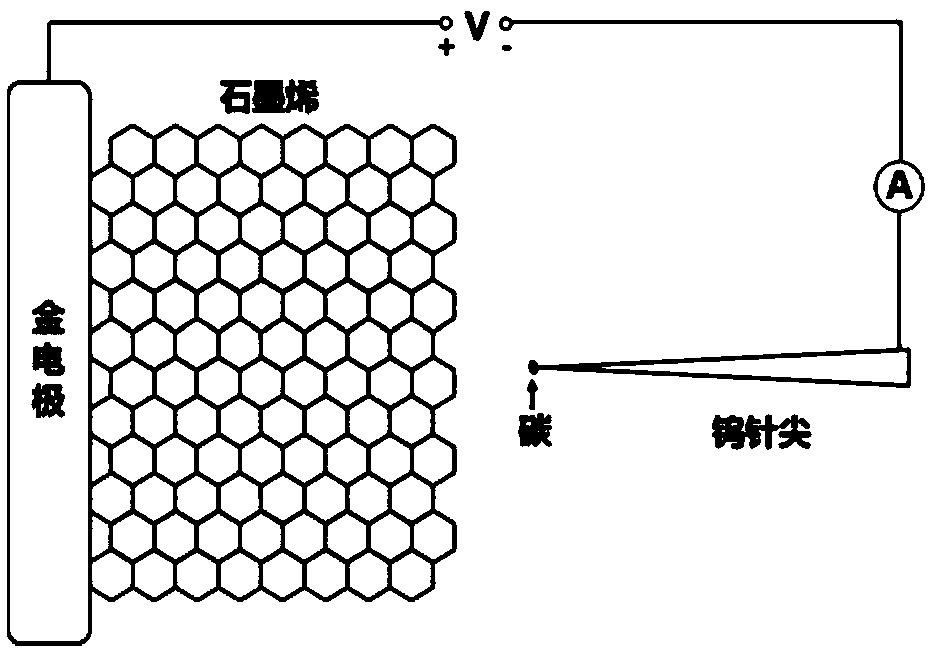

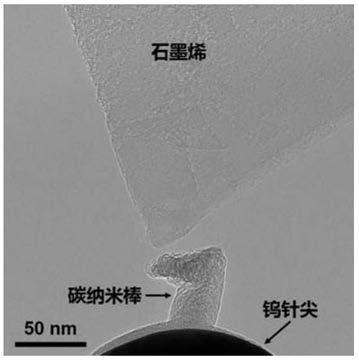

[0029] 1. Depositing carbon on the tip of the tungsten tip to make a nanoknife

[0030] A controllable nano-cut graphene method provided by the present invention is implemented in a transmission electron microscope, figure 1 It is a schematic diagram of the cutting process. The gold electrode is fixed, and the graphene is adhered to the edge of the gold wire electrode. The nanoknife made of tungsten needle tip and carbon structure can move in three dimensions, and the minimum step size can reach the nanometer scale. On the electrodes at both ends A bias v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com