Method facilitating conveying of partition wall with light ceramsites and formula of partition wall

A light-weight ceramsite and partition wall technology is applied in the field of light-weight ceramsite partition walls that are easy to transport and their formulations, and can solve the problems of explosive pipes, inability to implement, and easy to melt away.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

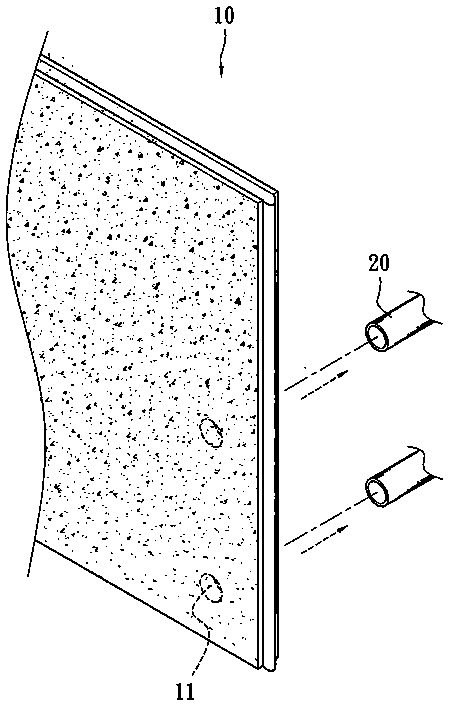

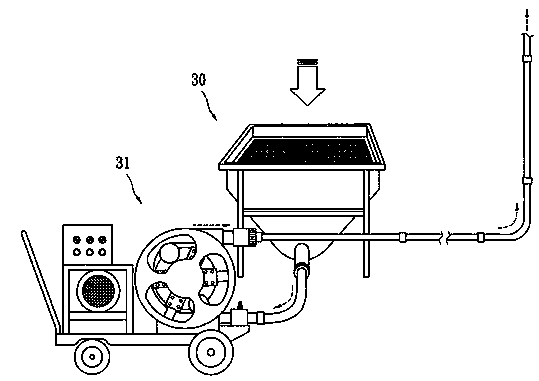

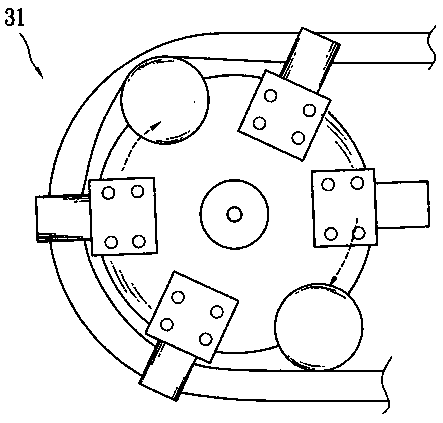

[0008] Embodiment: For the sake of having a more detailed and clear understanding of the purpose, effect and structural features of the present invention, the preferred embodiments of the present invention are cited and described in conjunction with the drawings as follows: please refer to the 6th figure, which is a comparative embodiment of the present invention As shown in the schematic diagram of transportation, the method shown in this embodiment is convenient for transportation with lightweight ceramsite partition walls, in which the foaming agent 61 used is 1%~3%, and the lightweight ceramsite 60 partition wall material is 97% ~99%, it is a kind of lightweight ceramsite 60 with a light specific gravity for the use of specific proportions. After being fully stirred by adding foaming agent 61, foams will be formed to facilitate the transportation of concrete pumps.

[0009] The present invention is a formula with lightweight ceramsite partition walls for easy transportation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com