Nonionic OP-10 compound asphalt emulsifier and application

An asphalt emulsifier, OP-10 technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of poor storage stability and emulsification effect, and achieve high density, high strength and good storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

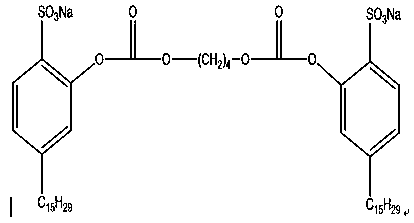

Method used

Image

Examples

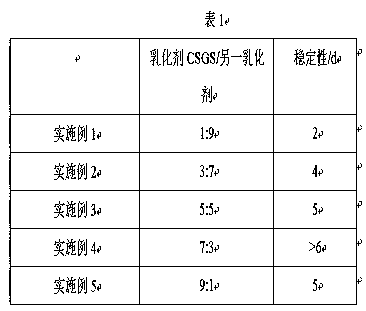

Embodiment 1

[0027] Add 39 parts of warm water at 68°C into the beaker, and then add 1 part of the compound emulsifier of CSGS and OP-10 to the warm water, where CSGS and OP-10 (molar ratio) are 9:1, and stir to make 40 parts evenly. Parts of the emulsifier aqueous solution. The emulsifier solution is mixed with 60 parts of 140°C petroleum pitch, and then a colloid mill is added for rubber grinding to prepare an emulsified pitch. The CSGS is dodecyl dimethyl ammonium bromide which is a Gemini cationic surfactant, and the dodecyl dimethyl ammonium bromide is produced by the reaction of dodecyl dimethyl ammonium bromide in sulfuric acid solution Dodecane bromide, in which the molar ratio of dodecyl alcohol and sulfuric acid to hydrogen bromide is 1:2:0.1, dodecane bromide reacts with N,N'-dimethylbenzylamine to make dodecane The molar ratio of dodecyl dimethyl ammonium bromide, dodecyl bromide and N,N'-dimethylbenzylamine is 1:1. The dodecyl dimethyl ammonium bromide is in the Henan Dao Pure...

Embodiment 2

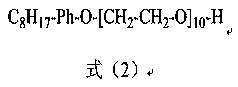

[0029] Add 39 parts of warm water at 68°C to the beaker, and then add 1 part of the compound emulsifier of CSGS and OP-10 to the warm water, where CSGS and OP-10 (molar ratio) are 7:3, and the mixture is evenly mixed to make 40 Parts of the emulsifier aqueous solution. The emulsifier solution is mixed with 60 parts of 140°C petroleum pitch, and then a colloid mill is added for rubber grinding to prepare an emulsified pitch. The CSGS is dodecyl dimethyl ammonium bromide, which is a Gemini cationic surfactant, which is purchased from Henan Daochun Chemical Co., Ltd.; in the compound emulsifier, OP-10 is nonylphenol polyoxyethylene Ether, purchased from Haian Petrochemical Co., Ltd.

Embodiment 3

[0031] Add 39 parts of warm water at 68°C to the beaker, and then add 1 part of the compound emulsifier of CSGS and octylphenol polyoxyethylene ether to the warm water, where the CSGS and octylphenol polyoxyethylene ether (molar ratio) is 5: 5. After stirring, make 40 parts of emulsifier aqueous solution evenly. The emulsifier solution is mixed with 60 parts of 140°C petroleum pitch, and then a colloid mill is added for rubber grinding to prepare an emulsified pitch. The CSGS is dodecyl dimethyl ammonium bromide, which is a Gemini cationic surfactant, purchased from Henan Daochun Chemical Co., Ltd.; in the compound emulsifier, OP-10 is nonylphenol polyoxyethylene Ether, purchased from Haian Petrochemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com