Photochromic Composite Fiber

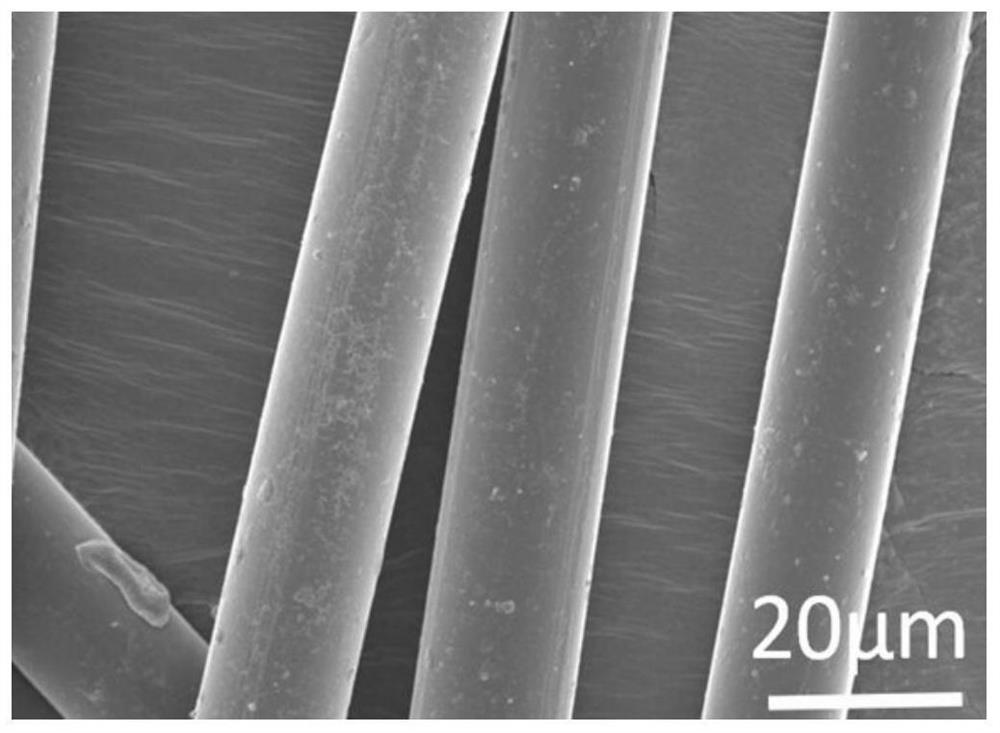

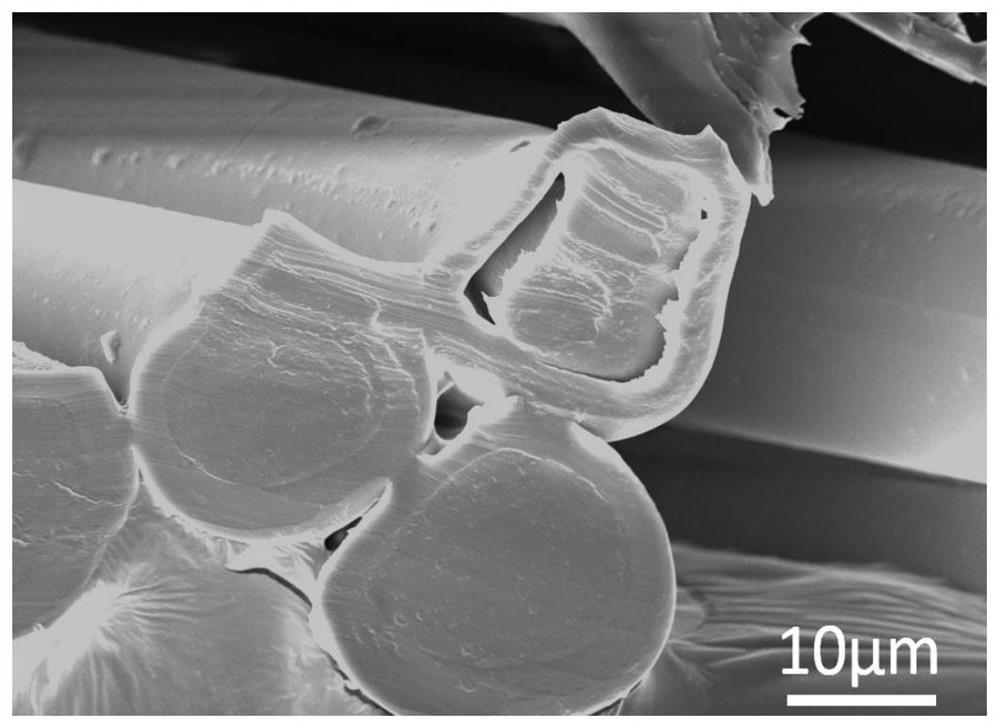

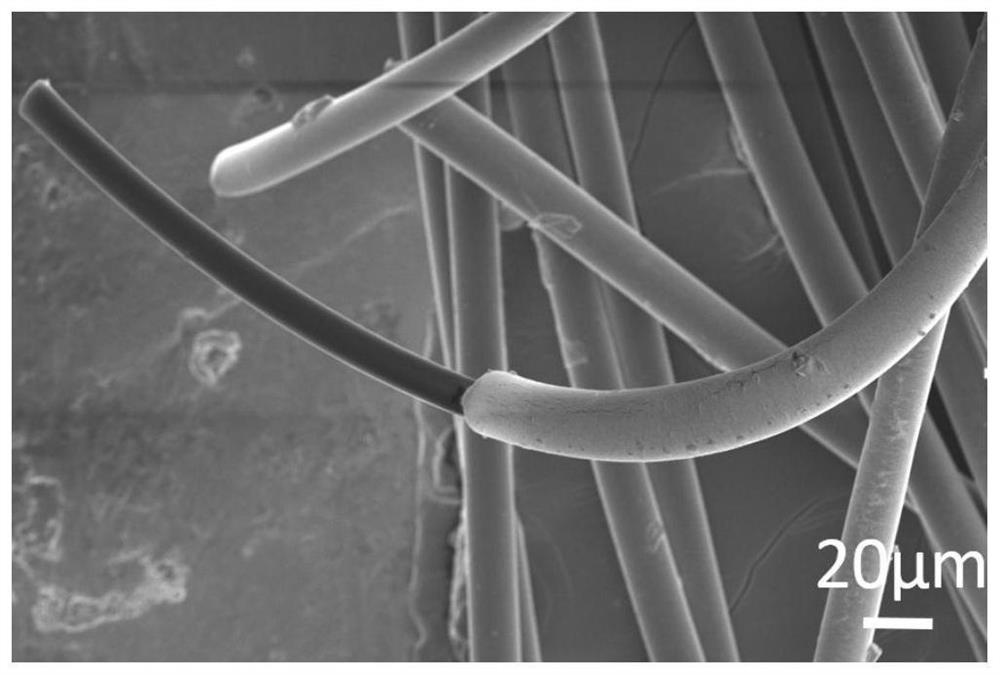

A composite fiber, photochromic technology, applied in the direction of fiber processing, fiber chemical characteristics, conjugated synthetic polymer rayon, etc., can solve the problems of easy decolorization, poor weather resistance, low color fastness, etc., to improve spinning The effect of speed and fiber strength, strong weather resistance, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] (1) The skin layer material is made of polyethylene terephthalate for drying and crystallization, the drying temperature is 200°C, so that the moisture content after drying is less than 30ppm, and then add 2% of the airtightness enhancer diisopropyl oxide according to the mass ratio , 0.5% flame retardant, and 0.4% softener are evenly mixed to obtain the leather layer material.

[0104] (2) Carry out drying and crystallization of the core material polypropylene, the drying temperature is 200°C, so that the moisture content after drying is less than 30ppm, and then add 5% of photochromic dye, 0.5% of dispersant, and 0.12% of coupling agent according to the mass ratio, 0.3% heat stabilizer, 0.09% antioxidant, 1% sensitizer, after mixing evenly, the core layer material can be obtained.

[0105] (3) Carry out spinning through the process of melt spinning, adjust the temperature of each zone of the torque rheometer and the screw extruder, wherein the screw temperature of the...

Embodiment 2

[0111] (1) The skin layer material polypropylene is dried and crystallized so that the moisture content after drying is less than 50ppm, and then the air tightness enhancer polyethylene naphthalate 1%, flame retardant 0.2%, and softener are added according to the mass ratio 0.04% can be obtained after mixing evenly.

[0112] (2) Dry and crystallize the core material polyethylene, so that the moisture content after drying is less than 50ppm, and then add 5% of photochromic dye, 0.2% of dispersant, 0.02% of coupling agent, and 0.03% of heat stabilizer according to the mass ratio , 0.01% of antioxidant, 0.1% of sensitizer, the core layer material can be obtained after mixing evenly.

[0113] (3) Spin through the process of melt spinning, adjust the temperature of each zone of the torque rheometer and the screw extruder, respectively extrude the core material and the skin layer material with photochromic dye, and then pass through the melt distribution pipe The mass ratio of the ...

Embodiment 3

[0118] (1) Dry and crystallize polycaprolactam as the skin layer material so that the moisture content after drying is less than 50ppm, then add 1% air tightness enhancer and 0.3% softener according to the mass ratio and mix evenly to obtain the skin layer material.

[0119] (2) Dry and crystallize the low-melting point polyester as the core material, so that the moisture content after drying is less than 50ppm, and then add 8% of photochromic dye, 0.4% of dispersant, 0.11% of coupling agent, and heat stabilizer according to the mass ratio 0.2%, 0.07% antioxidant, 2% sensitizer, after mixing evenly, the core layer material can be obtained.

[0120] (3) Spin through the process of melt spinning, adjust the temperature of each zone of the torque rheometer and the screw extruder, respectively extrude the core material and the skin layer material with photochromic dye, and then pass through the melt distribution pipe The metering is to control the mass ratio of the skin layer to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com