Environment-friendly mining design method for mine mining, screening, pressure relief , drainage and filling

A design method and green technology, applied in mining equipment, ground mining, earthwork drilling, etc., can solve problems such as mining conditions without protective layer, save coal gangue lifting and transportation costs, improve mine resource recovery rate and , The effect of preventing environmental pollution and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

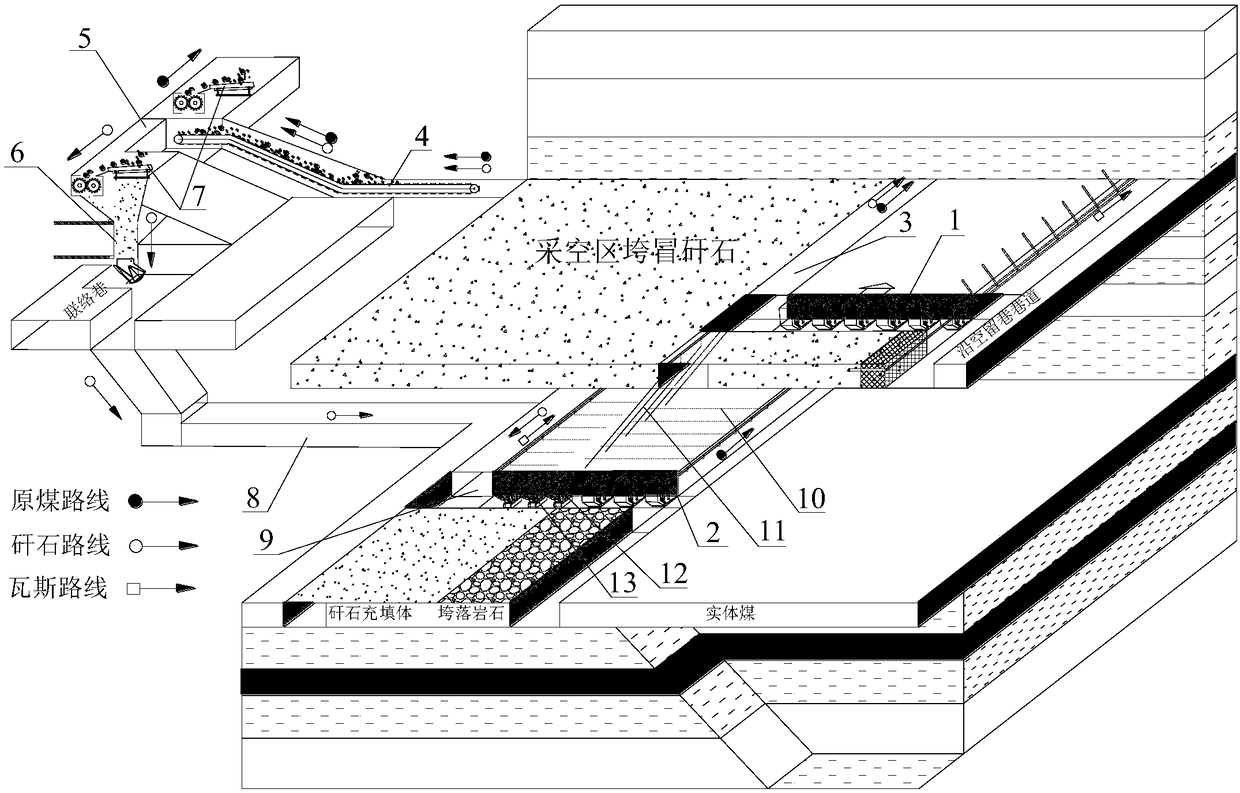

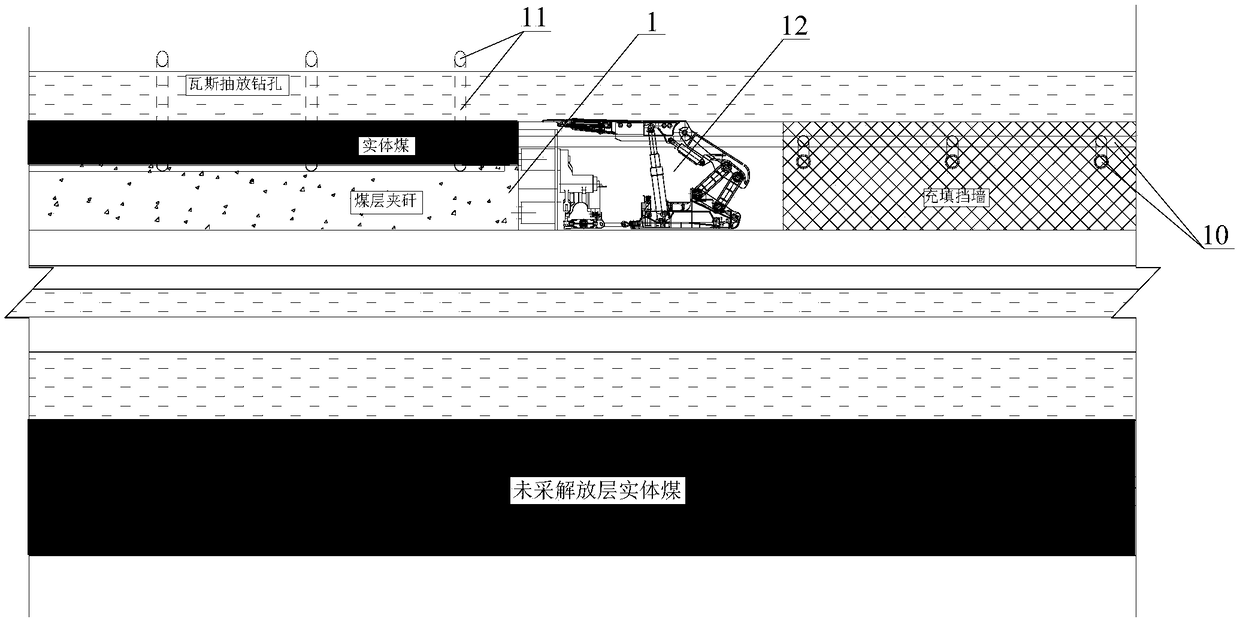

[0031] Such as figure 1 and figure 2 As shown, a green mining design method for mining, selection, unloading, pumping and charging, the design process is as follows:

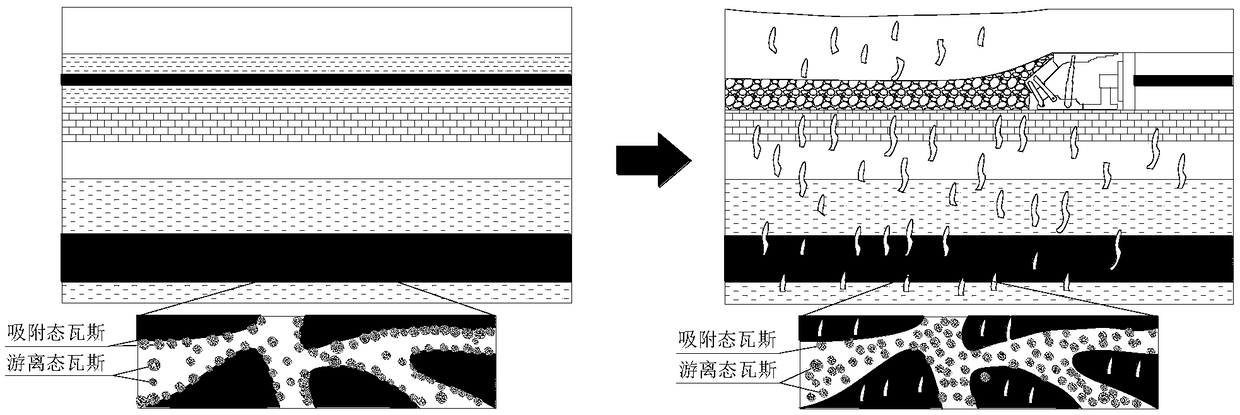

[0032] The first step is to analyze the coal seam thickness and layer spacing distribution characteristics of the near-total-rock protective layer, and arrange a fully-mechanized mining face 1 in the protective layer to realize the mining of the near-total-rock protective layer; A method of combining mining and breaking rock technology. When the thickness of the rock layer is less than 0.6m, use fully mechanized mining equipment to break the rock; when the thickness of the rock layer is more than 0.6m, drill holes in the rock layer and pre-split with vibrating guns to break the thicker and complete rock layer, and then use the shearer to cut , in the coal mining process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com