Volute of turbo-expander

A turbo-expansion and turbo-turbine technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as the inability to accurately reflect the performance of the expander, the hidden dangers of the safety of the turbo-expander, and the difficulty in meeting quick shutdown, etc. Achieve the effect of improving the accuracy of data collection, small measurement errors, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

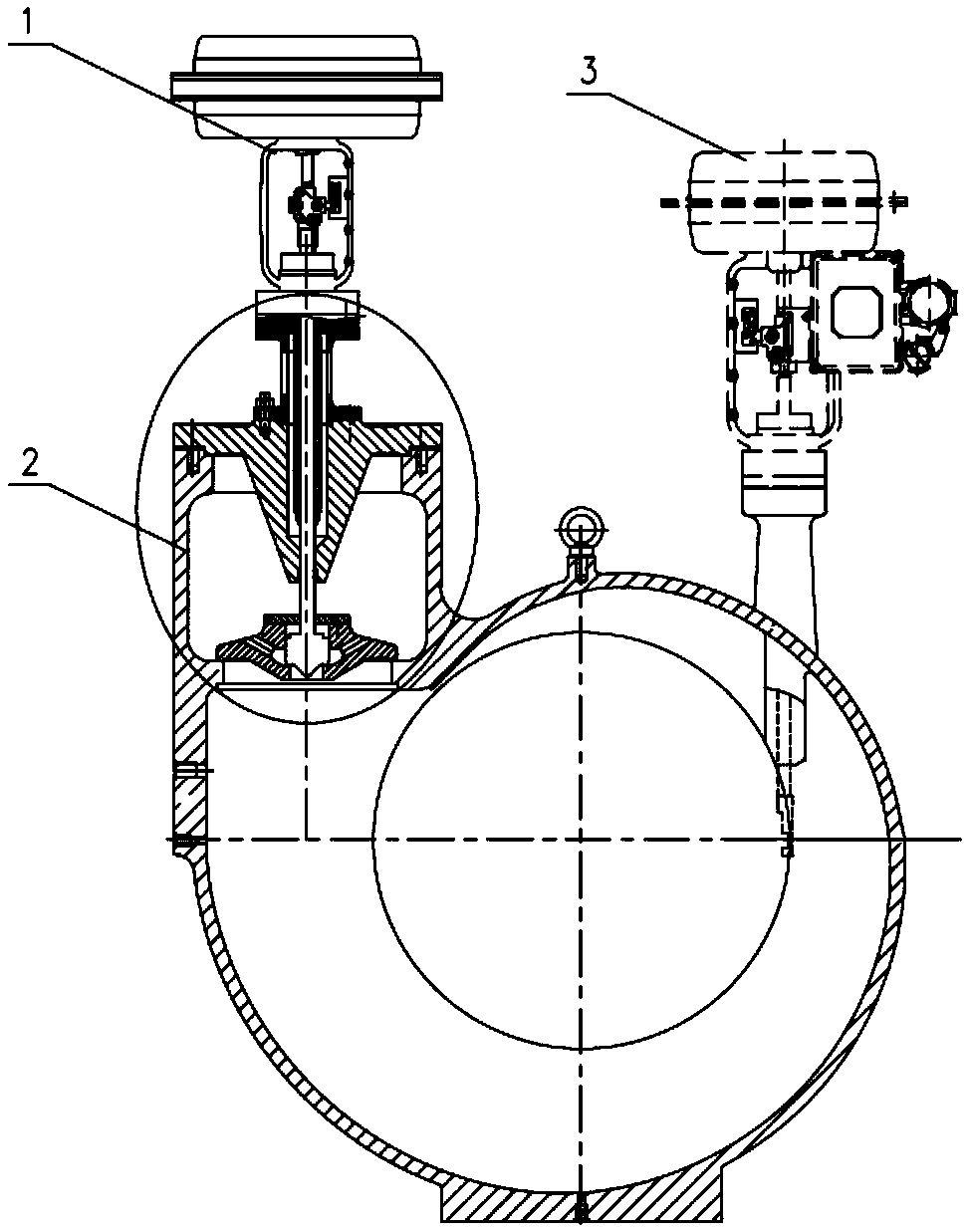

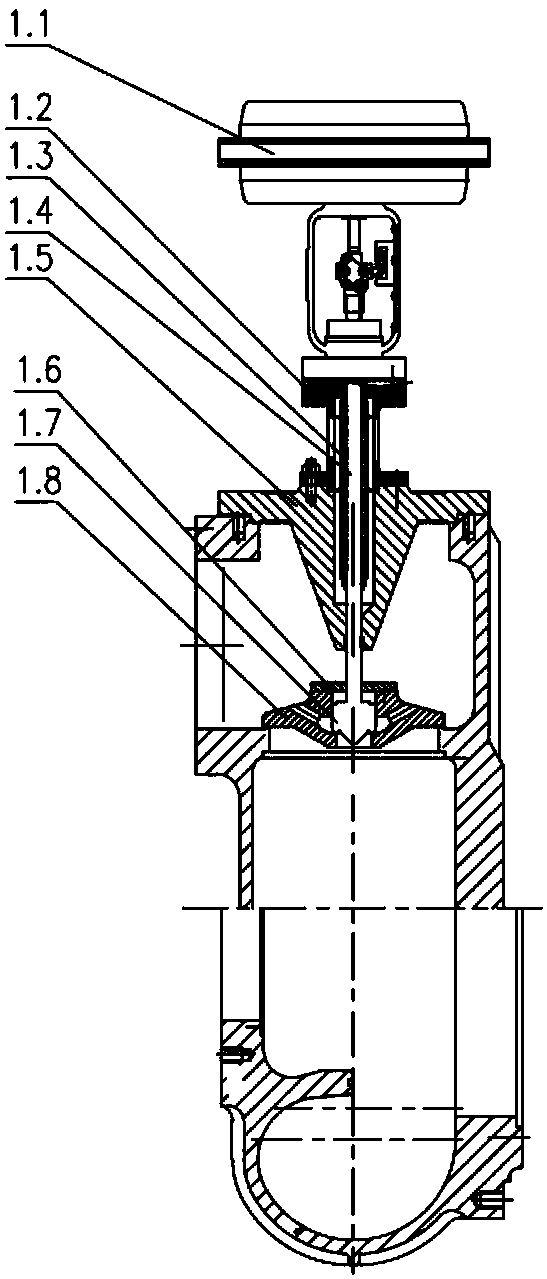

[0036] Depend on figure 1 From the structural schematic diagram of the turbo expander volute shown, it can be seen that the turbo expander volute of the present invention mainly includes a volute 2 and a quick-closing valve 1 for closing the air inlet at the air inlet.

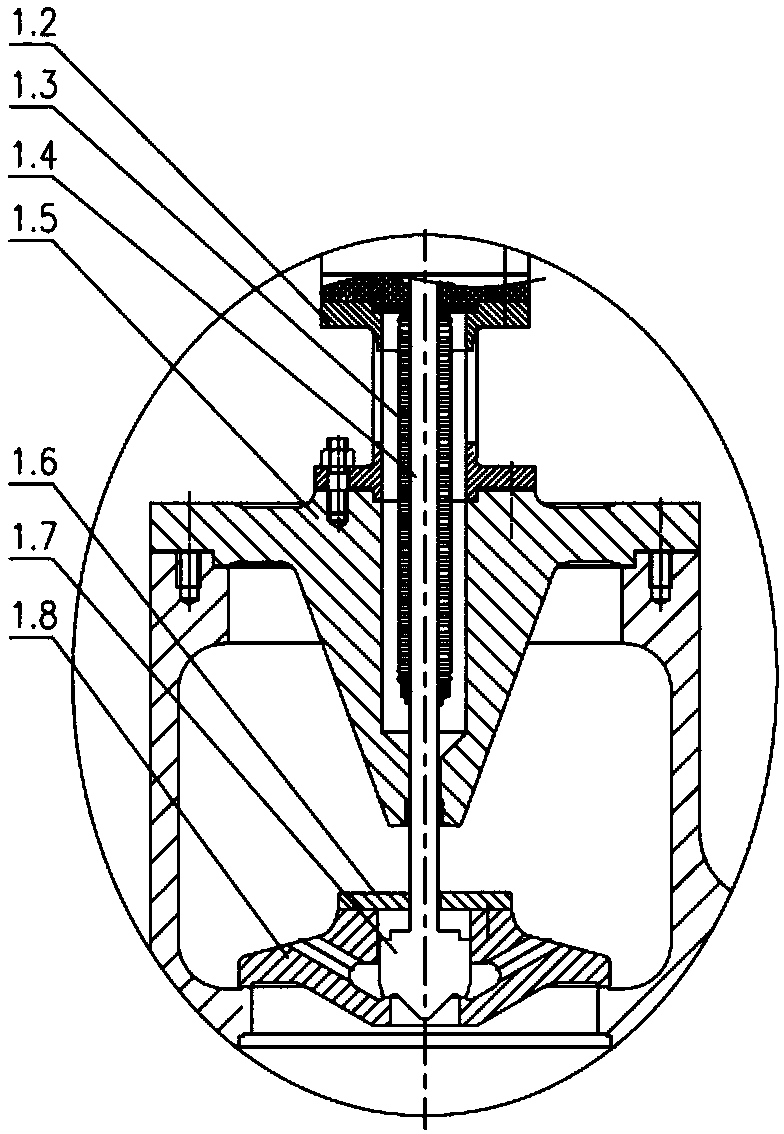

[0037] As a specific embodiment, the quick-closing valve 1 includes a valve stem 1.4 driven by a pneumatic, hydraulic or electromagnetic drive device 1.1, a valve disc 1.8 that cooperates with the air inlet on the inner wall of the volute 2, a valve disc cover 1.6, And the pre-opening valve body 1.7;

[0038] The quick-closing valve 1 can be manually or automatically controlled and interlocked by signals from control systems such as PLC or DCS. When the measured values such as speed, vibration, oil temperature and oil pressure obtained by an instrument exceed the set value of the interlock, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com