Three-level intelligent combined control system for mine local fan

A local ventilation and control system technology, applied in mine/tunnel ventilation, pump control, mining equipment, etc., can solve problems that cannot be put into practical application, fuzzy control, gas overrun, etc., to shorten the accident response time, maintenance and Easy to upgrade and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail in combination with the embodiments and accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. The technical solutions of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the scope of protection is not limited thereto.

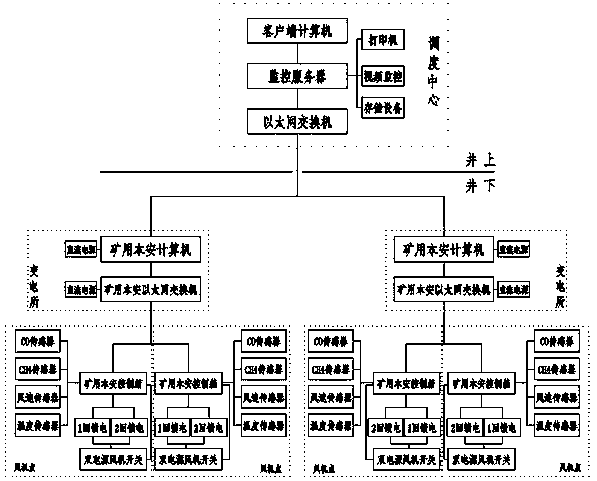

[0023] Such as figure 1 As shown, a three-level intelligent joint control system for local ventilators of the present invention is mainly composed of three-level parts, and the first-level ground dispatching center is composed of a client computer, a monitoring server and its software, etc., and this part constitutes the control system on the well; It is mainly responsible fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com