System and method for realizing humidity calibration function based on temperature and humidity sensor

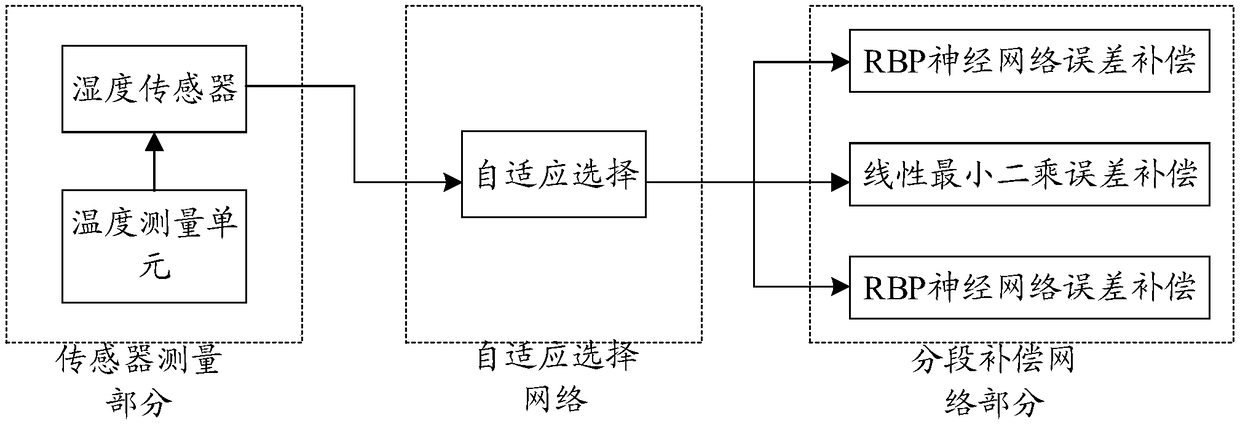

A temperature and humidity sensor, temperature and humidity technology, applied in thermometer testing/calibration, thermometers, instruments, etc., can solve problems such as large amount of calculation, many temperature and humidity data points, poor practicability, etc., to ensure consistency, small amount of calculation, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

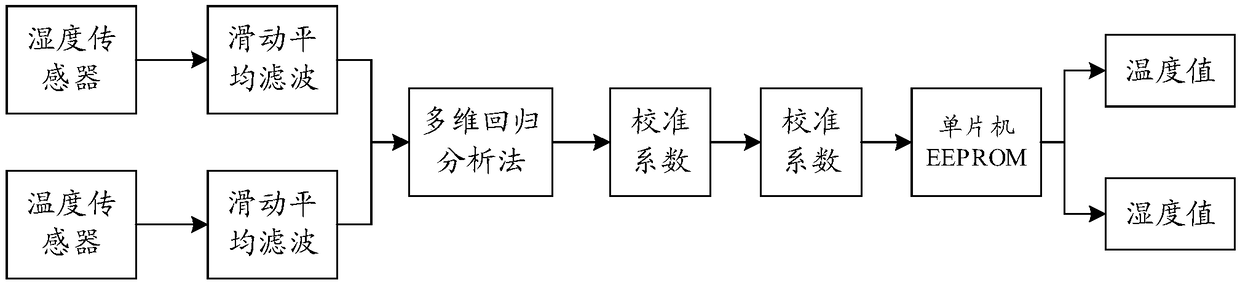

Method used

Image

Examples

Embodiment Construction

[0048] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

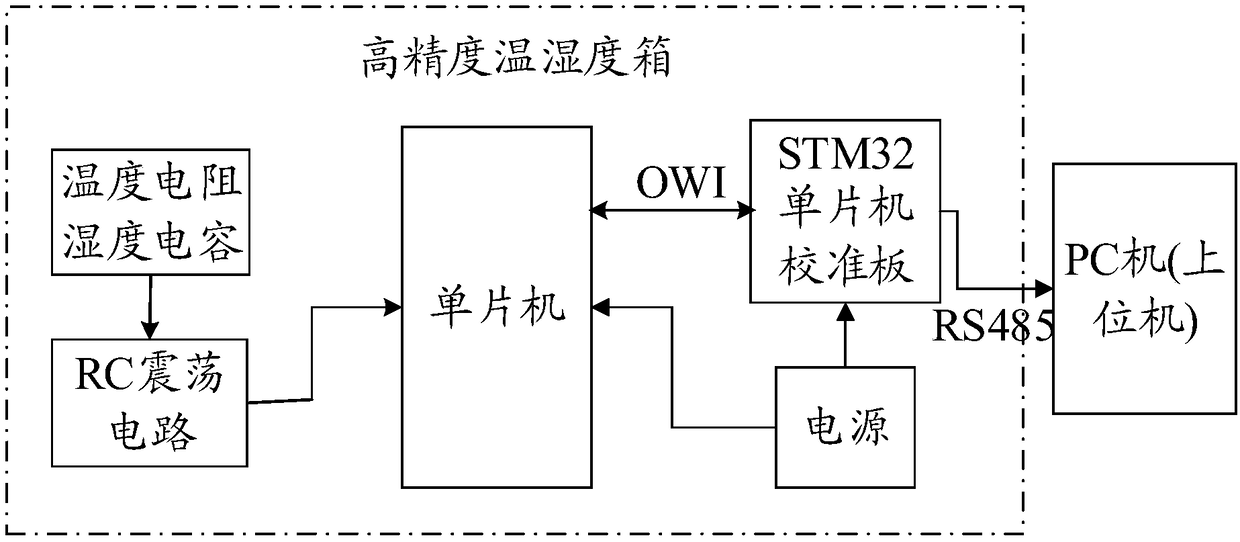

[0049] The system for realizing the humidity calibration function based on the temperature and humidity sensor, wherein the system includes:

[0050] The temperature and humidity integrated sensor, including temperature resistance and humidity capacitance, is placed in a high-precision calibration temperature and humidity box to detect temperature and humidity;

[0051] An RC oscillator circuit is connected with the temperature and humidity integrated sensor, and is used to output a certain temperature and humidity frequency value;

[0052] The single-chip microcomputer is connected with the RC oscillating circuit, and is used to calculate the humidity value H according to the temperature and humidity frequency value;

[0053] The STM32 microcontroller calibration board is connected with the microcontrolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com