Device and method applied to ion beam etching sputtering protection

A technology of ion beam etching and scribing, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of poor uniformity, out-of-tolerance etching groove depth of thrust plate, splash, and finally impact from different angles, etc., to achieve Ensure consistency, good uniformity, and avoid the effect of etching groove depth out of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

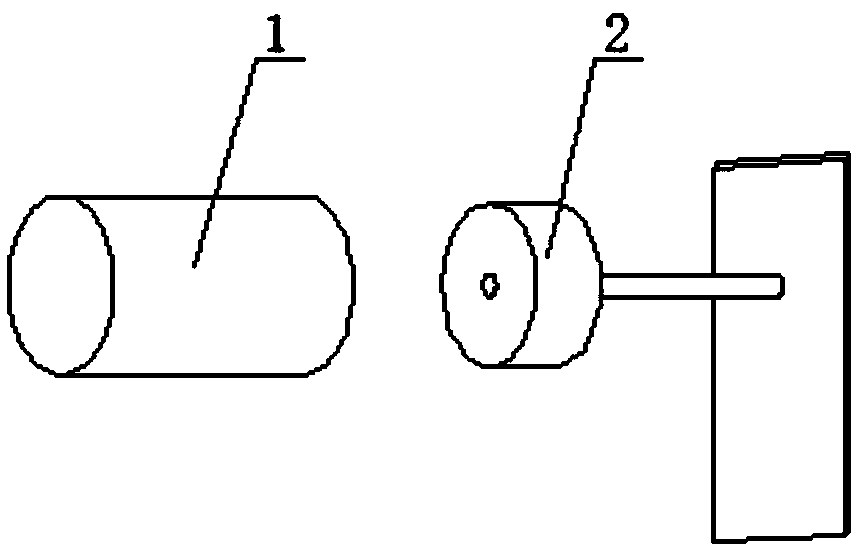

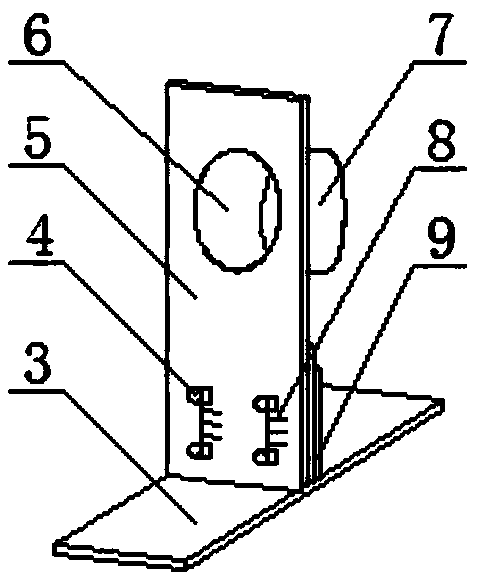

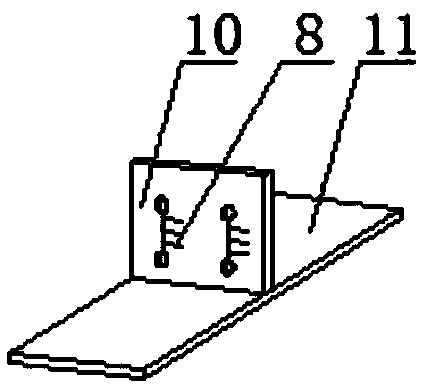

[0023] Such as figure 2 -- Figure 4 As shown, a device applied to ion beam etching and sputtering protection includes a front support 5, a base support 3 and a cylindrical shielding tube 7, the front support is vertically arranged, and the lower part of the front support is installed on the base support. The structure is: the base support includes a base plate 11 and a vertical plate 10, the vertical plate is vertically installed on the base plate, and the vertical plate is fixedly connected with the bottom of the front support through a pressing plate 9 and screws 4. Both the front bracket and the base bracket are provided with engraved lines 8, and the position of the cylindrical shielding cylinder can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com