Automatic classification package method and system of semiconductor device

A packaging method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as defects, improve product quality and machine efficiency, improve efficiency and quality, and facilitate monitoring and analysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

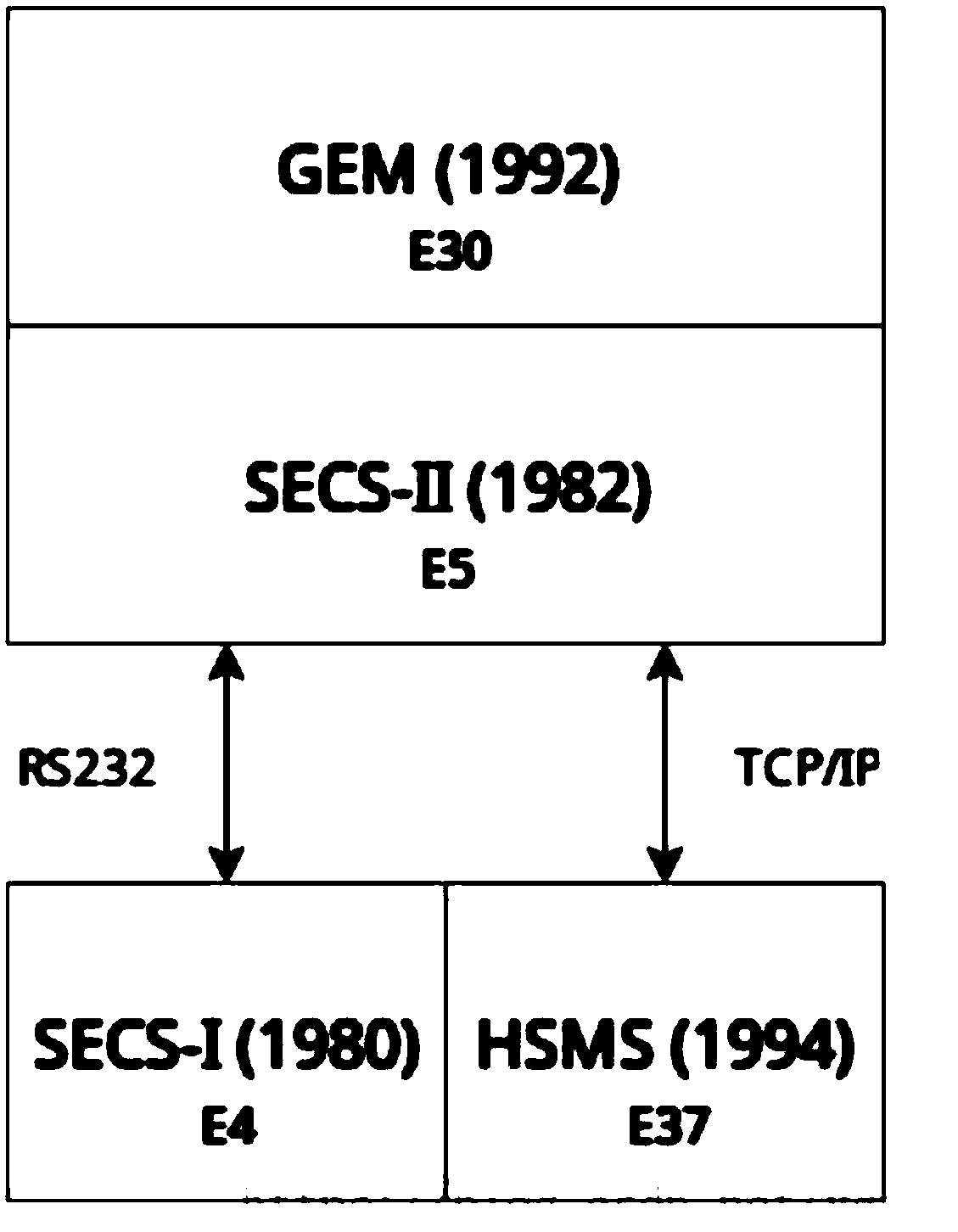

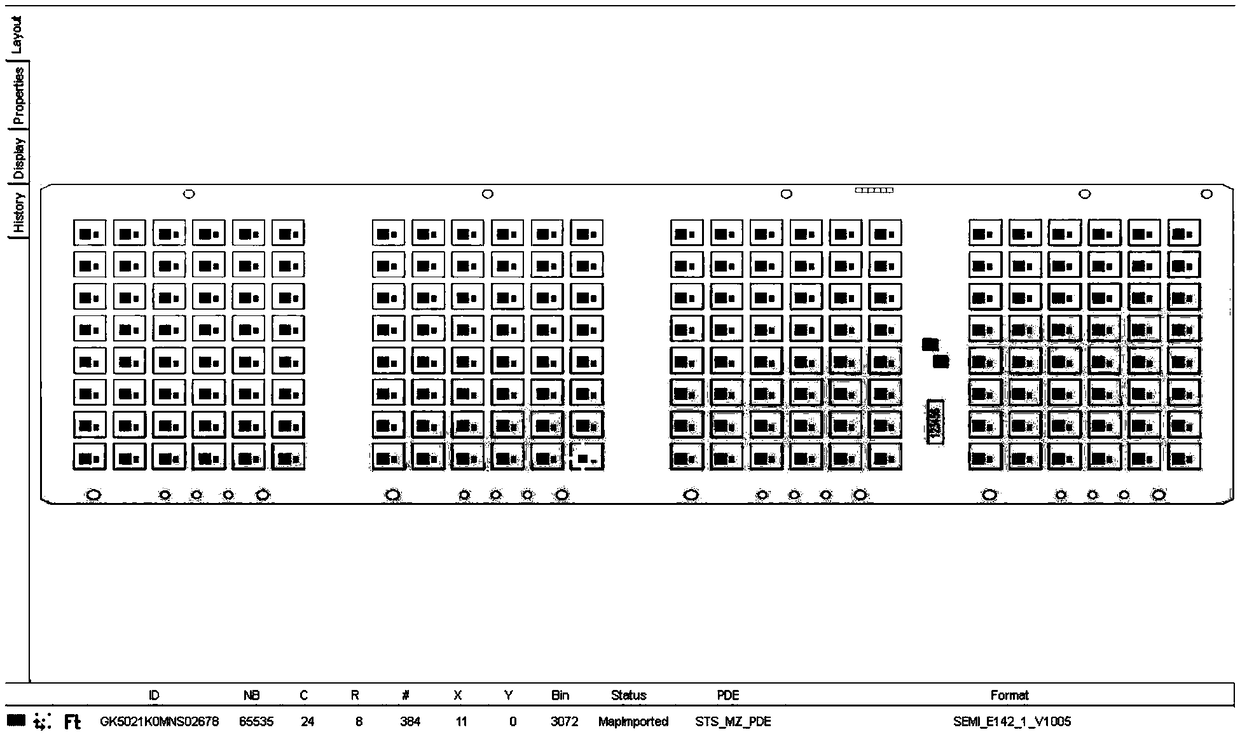

[0252] According to the first embodiment of the automated hierarchical packaging method for semiconductor devices of the present invention, the traceability information of the semiconductor device includes batch, coordinate, and grading information; The above-mentioned semiconductor devices are packaged; a plurality of the above-mentioned semiconductor devices are arranged on the carrier in an array.

[0253] Understandably, as an example, referring to image 3 And the XML file of the sensor placement station above, in Figure 4 The STEWOKStrip has four blocks, each block has 8×6 packages, and each package includes two chips: emitter and sensor. The semiconductor device corresponds to the package body, therefore, in Figure 4 In an example, the semiconductor device includes two chips. Therefore, there are three types of traceability information of the semiconductor device: traceability information of the package body, traceability information of the transmitter chip,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com