Storage container and storage method of z-1-chloro-3, 3, 3-trifluoropropene

A technology for preserving containers and containers, which is applied in the direction of containers, ceramic containers, rigid containers, etc., can solve the problems of large impact, and achieve the effect of safe and stable storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] In this example, use an internal volume of 19800cm 3 An iron (SPCC) container (manufactured by DAIKAN Co., Ltd., model number 20C-285T-100810) was used as the storage container main body. The plate thickness of the iron container is 0.8mm (container trunk) and 1.0mm (top and bottom). The material of the liquid contact part is epoxy-phenolic resin (manufactured by Toyo Ink Co., Ltd., model E-90-NSP), and the thickness is about 5 μm. About 2 kg of HCFO-1233zd(Z) (purity: 99.97%) was placed in this storage container for HCFO-1233zd(Z), and the screw cap was tightened, and it was left to stand at normal temperature for 6 months.

Embodiment 1 and

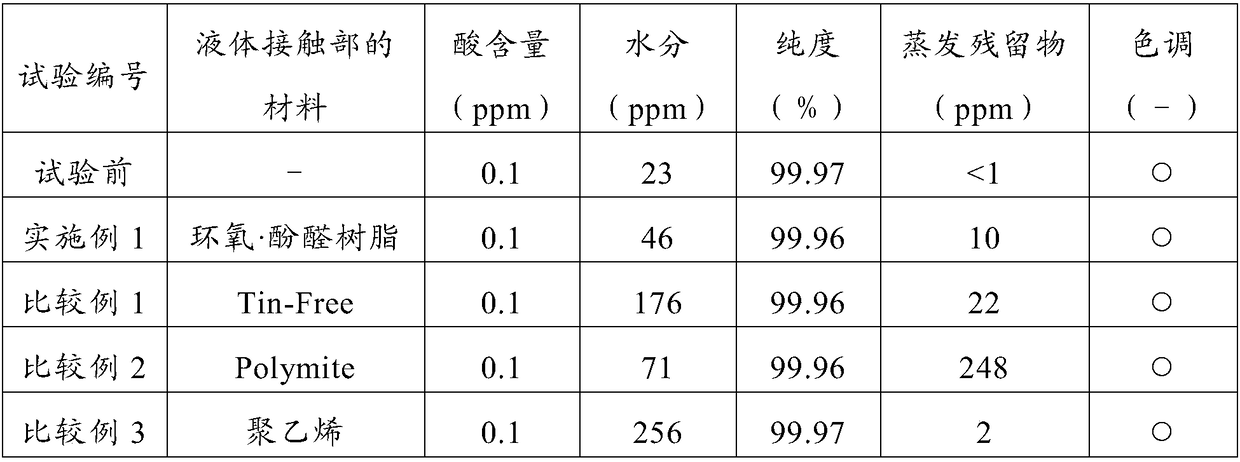

[0135] Table 1 shows the analysis results of the acid content, water content, purity, evaporation residue, and color tone of Example 1 and Comparative Examples 1 to 3. Table 1 shows the analysis results of acid content, moisture, purity, evaporation residue, and color tone of HCFO-1233zd(Z) (purity: 99.97%) before storage.

[0136]

[0137]

[0138] In Comparative Example 1 and Comparative Example 3, a significant increase in water content was observed. With respect to Comparative Example 2, a significant rise in evaporation residue was observed. On the other hand, in Example 1, the acid content, moisture, purity, and evaporation residue contained in HCFO-1233zd(Z) were within the range of error and did not change significantly before and after the test.

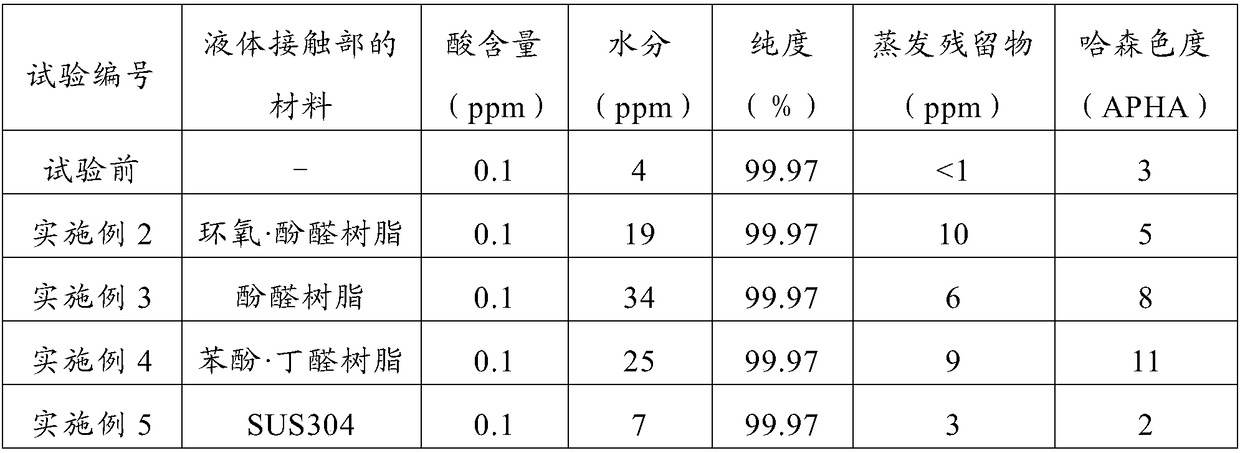

Embodiment 2

[0140] In this example, use an internal volume of 19800cm 3 An iron (SPCC) container (manufactured by DAIKAN Co., Ltd., model number 20C-285T-100810) was used as the storage container main body. The plate thickness of the iron container is 0.8mm (container trunk) and 1.0mm (top and bottom). The material of the liquid contact part is epoxy-phenolic resin (manufactured by Toyo Ink Co., Ltd., model E-90-NSP), and the thickness is about 5 μm. About 2 kg of HCFO-1233zd(Z) (purity: 99.97%) was placed in this storage container for HCFO-1233zd(Z), and the screw cap was tightened, and left still at 35° C. for 6 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com