Rotary electric machine and manufacturing method for rotary electric machine

A technology for rotating electric machines and manufacturing methods, applied in the direction of manufacturing motor generators, using/manufacturing slot locking devices, electrical components, etc., can solve problems such as hammering installation difficulties, magnetic wedge practical difficulties, etc., and achieve high motor efficiency and less loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

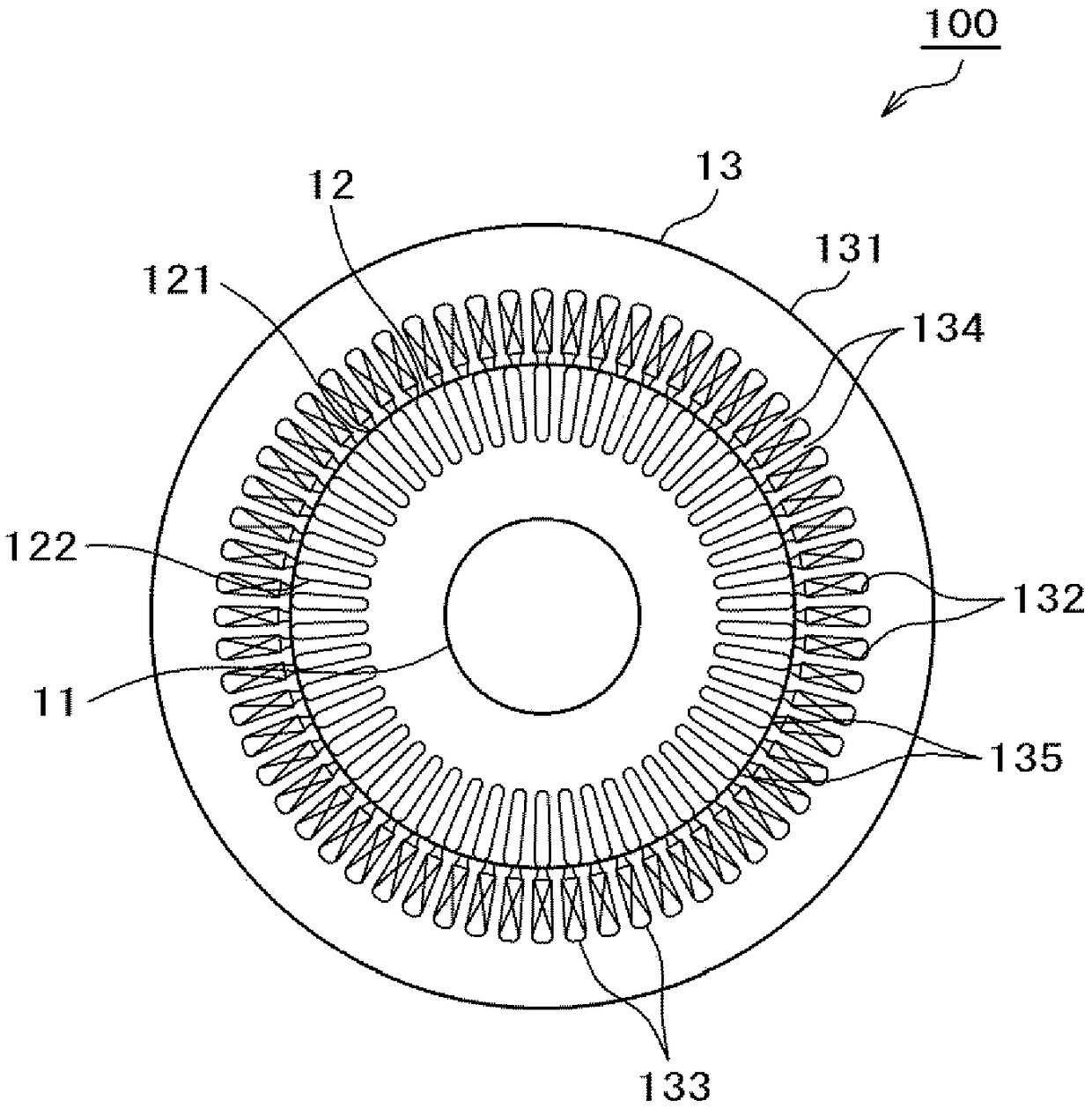

[0040] Below, use Figure 1 ~ Figure 13 Example 1 will be described. Such as figure 1 with figure 2 As shown, the rotating electric machine 100 has a rotor 12 fixed on a rotating shaft (hereinafter also referred to as a shaft) 11 and a stator 13 provided outside the rotor 12.

[0041] The rotor 12 has a rotor core 121 which is a laminated core formed by laminating electromagnetic steel sheets punched into a predetermined shape, and a secondary conductor 122 inserted into the slot of the rotor core 121. The rotor core 121 is fixed to the rotating shaft 11 and is provided so that the rotor 12 can rotate as the rotating shaft 11 rotates.

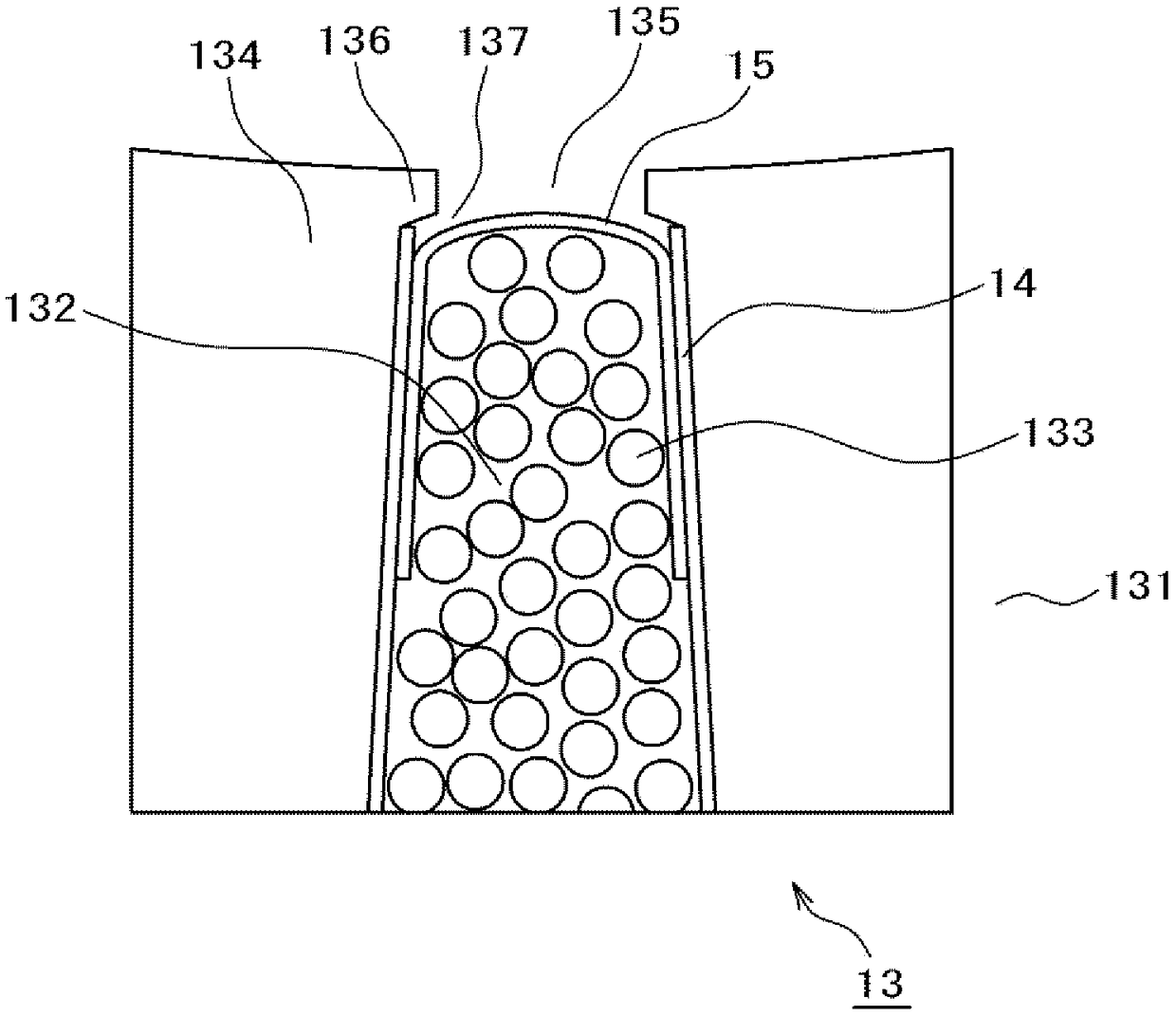

[0042] The stator 13 has a stator core 131 which is a laminated core formed by laminating soft magnetic thin plates such as electromagnetic steel sheets punched into a predetermined shape, and a coil 133 inserted into a slot 132 of the stator core 131. The stator core 131 is arranged to face the circumferential surface of the rotor 12. In additio...

Embodiment 2

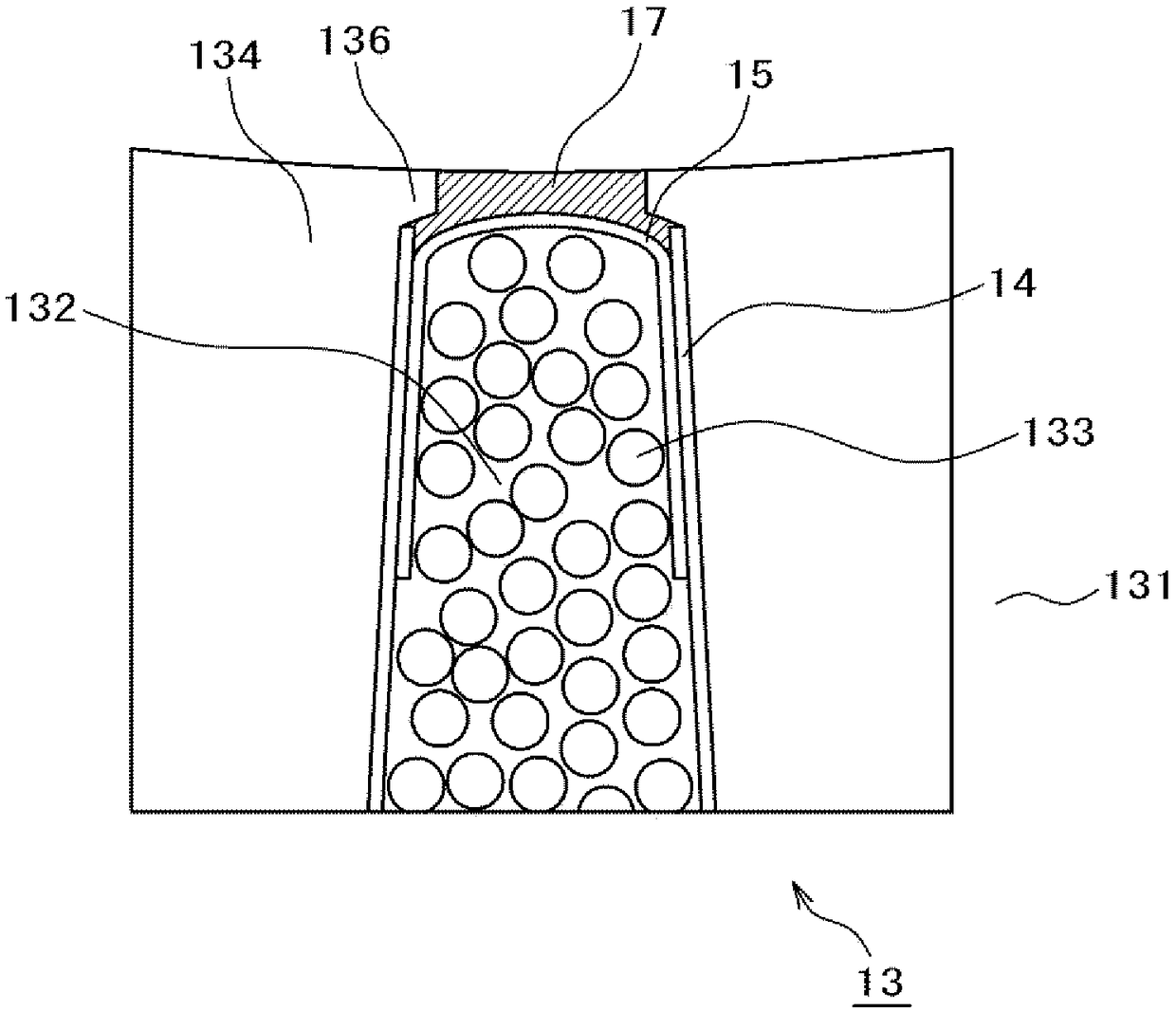

[0085] Hereinafter, for the manufacturing method of the rotating electric machine of Example 2, use Figure 14 Be explained. Example 2 is an aspect in which a mixture of soft magnetic powder and a resin material is cured in advance to form a rigid mixture 17 and then attached to the groove opening 135. In addition, the rotating electric machine applied in the second embodiment has the same structure as the rotating electric machine 100 applied in the first embodiment except for the difference in the shape and arrangement of the slot liner as described later.

[0086] First, the soft magnetic powder and the resin material are mixed, and the mixture is formed into a shape that can fit into the groove opening 135, and then the resin material contained in the mixture is cured to form the mixed body 17. Next, insert the coil 133 into the slot 132 and push it into the bottom side of the slot 132 while bending the rotor 12 side end of the slot liner 20 toward the center side of the slot...

Embodiment 3

[0104] in Figure 15 An enlarged view of the vicinity of the slot opening of the stator core is shown in FIG.

[0105] In the storage portion 139 of the slot 132 of the stator core 131, a slot liner 14 as an insulator, a winding 133, and a slot liner (or cap) 15 as an insulator are inserted from the outer peripheral side. The slot liner 14 on the outer peripheral side insulates the winding 133 from the teeth 134. In addition, the slot liner 15 on the inner peripheral side has a function of preventing the winding 133 from protruding from the end of the slot opening 135 to the rotor core side in addition to the function of insulation. The winding 133 is, for example, a coil formed by winding a conductor such as an enameled copper wire around the teeth 134.

[0106] Regarding the shape of the slot 132 of the stator core 131 with the slot opening 135 along the inner diameter of the stator core, a full-open type (open) slot is mainly used in large-sized rotating machines, and a half-op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com