Long-stroke screw rod locking mechanism on hydraulic press dedicated to SMC composite

A composite material and locking mechanism technology, applied in presses, manufacturing tools, etc., can solve the problems of increased failure points, increased manufacturing costs, waste of resources, etc., to reduce equipment costs, shorten the length of oil cylinders, and facilitate disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

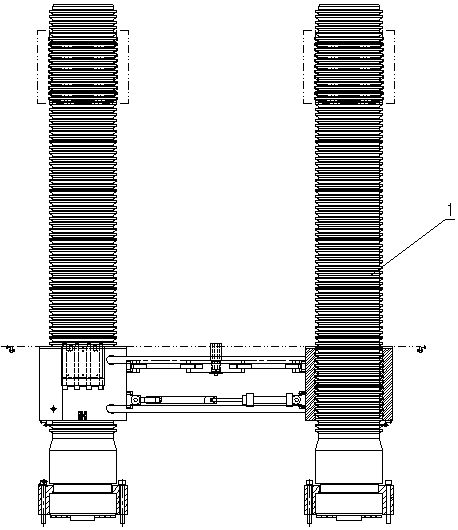

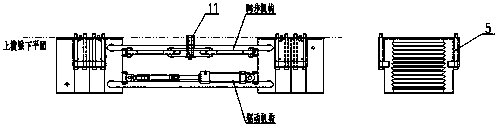

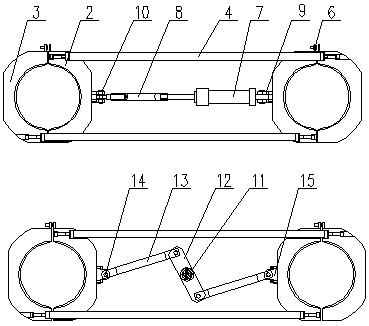

[0021] See attached picture: figure 1 , 2 Shown in , 3 is a specific embodiment of the present invention, which is a long-stroke screw locking mechanism installed in a 4000T SMC composite material special hydraulic press. Its structure includes a long-stroke screw column 1 connected to the upper plane of the plunger rod of the short-stroke clamping cylinder inside the hydraulic press slider, which moves up and down with the slider, and the locking device, drive mechanism and synchronization mechanism are connected to each other, and are installed on the hydraulic press as a whole. On the lower plane of the beam, the locking device moves left and right along the guide block 5 under the drive of the driving mechanism to lock the long-stroke screw column 1.

[0022] The locking device is composed of active nut block 2, follower nut block 3, connecting rod 4, guide block 5 and detection switch 6, and each set of lock nuts is left and right, respectively composed of active nut blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com