Soft and hard integrated composite material with shape memory function as well as preparation method and application thereof

A composite material and memory technology, which is applied in the field of soft and hard integrated composite materials and preparation, can solve the problems of complicated manufacturing process, high cost, and increased carbon emissions, and achieve the effects of reducing manufacturing costs, wide application range, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

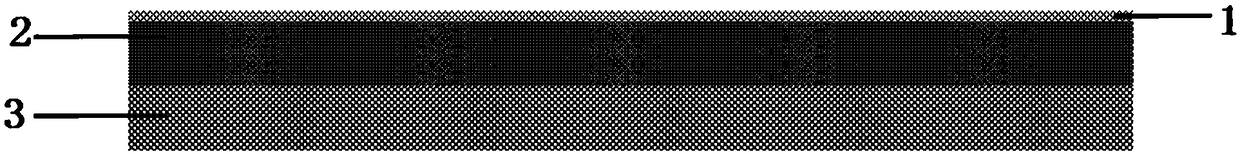

Image

Examples

Embodiment 1

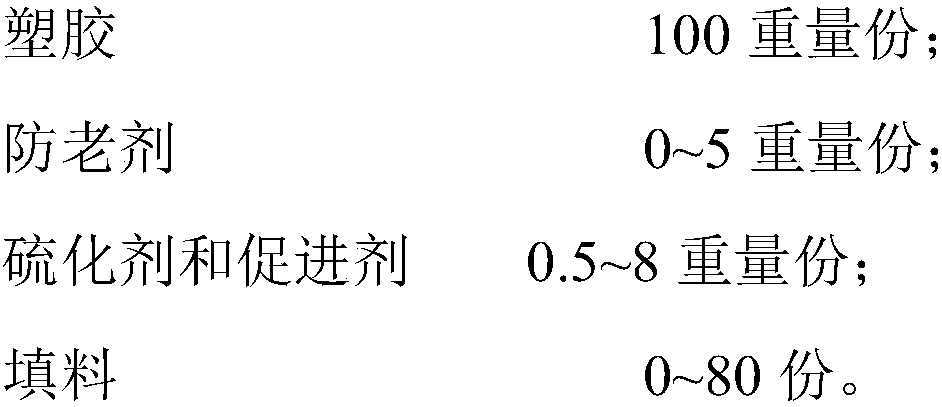

[0052] The specific formula of the protective layer is:

[0053] Polycaprolactone (plastic) 100 parts

[0054] DCP 0.5 copies

[0055] Titanium dioxide (filler) 5 parts

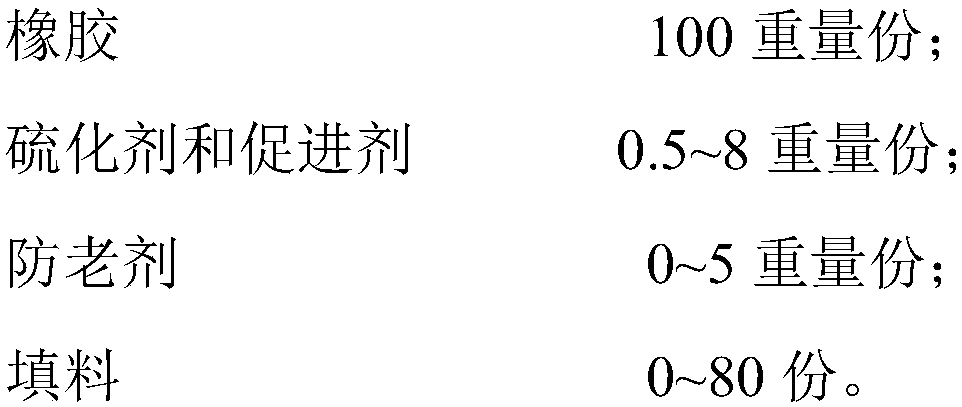

[0056] The specific formula of the soft lining is:

[0057]

[0058] According to the above protective layer formula and soft lining formula, according to the traditional rubber milling, banburying, kneading or extrusion mixing process, according to the feeding sequence of rubber-activator-filler-softener-anti-aging agent-vulcanizing agent, respectively The above two formulas are mixed to obtain semi-finished products of mixed rubber for the protective layer and semi-finished products of mixed rubber for the soft lining layer, which are stored for more than 16 hours for use. The kneading temperature of the protective layer is 60°C±10°C; the kneading temperature of the soft lining is normal temperature plus cooling water circulation cooling.

[0059] According to the proportion of 50%, weigh the same am...

Embodiment 2

[0063] The specific formula of the protective layer is:

[0064]

[0065] The specific formula of the soft lining is:

[0066]

[0067] According to the above protective layer formula and soft lining formula, according to the traditional rubber milling, banburying, kneading or extrusion mixing process, according to the feeding sequence of rubber-activator-filler-softener-anti-aging agent-vulcanizing agent, respectively The above two formulas are mixed to obtain semi-finished products of mixed rubber for the protective layer and semi-finished products of mixed rubber for the soft lining layer, which are stored for more than 16 hours for use. The kneading temperature of the protective layer is 70°C±10°C; the kneading temperature of the soft lining is normal temperature plus cooling water circulation cooling.

[0068] According to the volume ratio of 1:9, weigh 1 volume part of the protective layer compound rubber and 9 volume parts of the soft lining layer compound rubber...

Embodiment 3

[0073] The specific formula of the protective layer is:

[0074]

[0075] The specific formula of the soft lining is:

[0076]

[0077] According to the above protective layer formula and soft lining formula, according to the traditional rubber milling, banburying, kneading or extrusion mixing process, according to the feeding sequence of rubber-activator-filler-softener-anti-aging agent-vulcanizing agent, respectively The above two formulas are mixed to obtain semi-finished products of mixed rubber for the protective layer and semi-finished products of mixed rubber for the soft lining layer, which are stored for more than 16 hours for use. The kneading temperature of the protective layer is 80°C±10°C; the kneading temperature of the soft lining is normal temperature plus cooling water circulation cooling.

[0078] According to the volume ratio of 3:7, weigh 3 parts by volume of the protective layer compound rubber and 7 parts by volume of the soft lining layer compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap