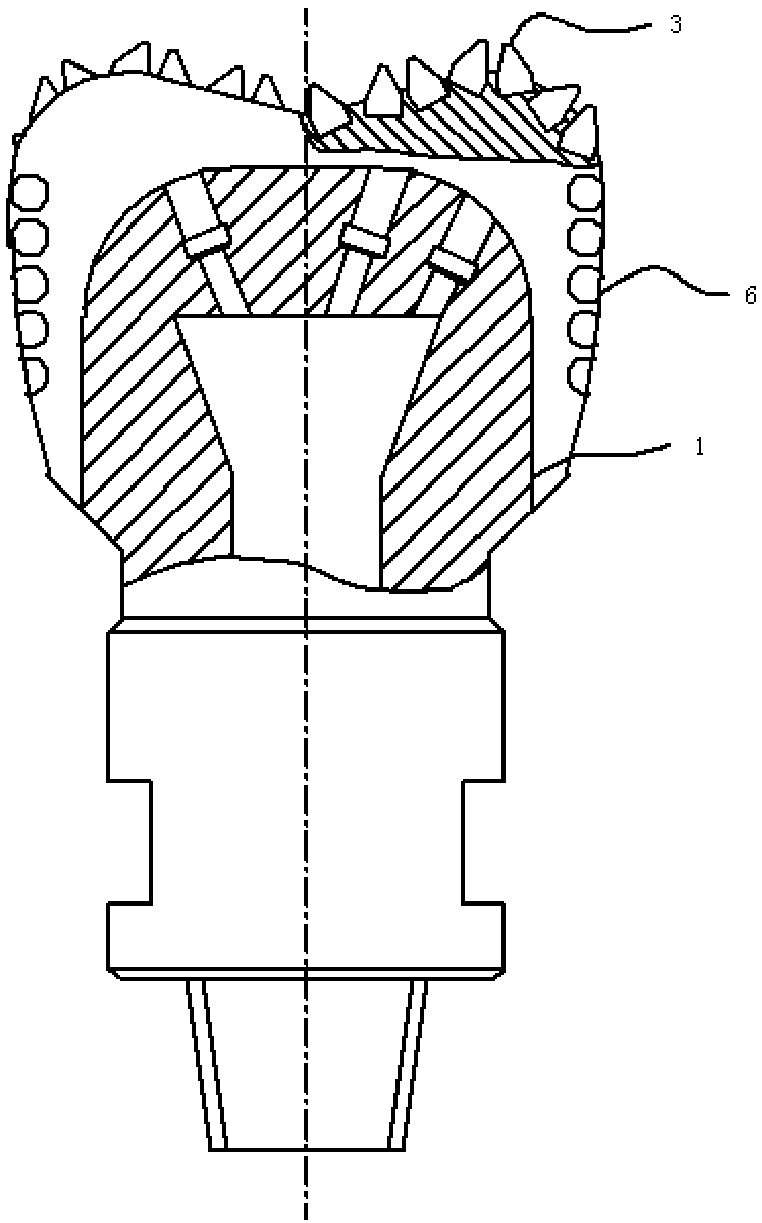

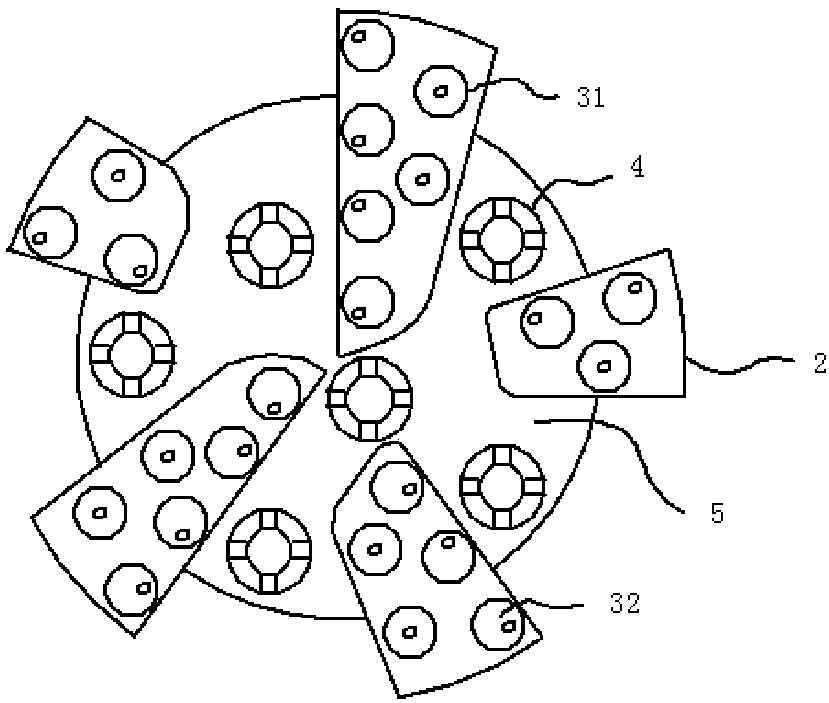

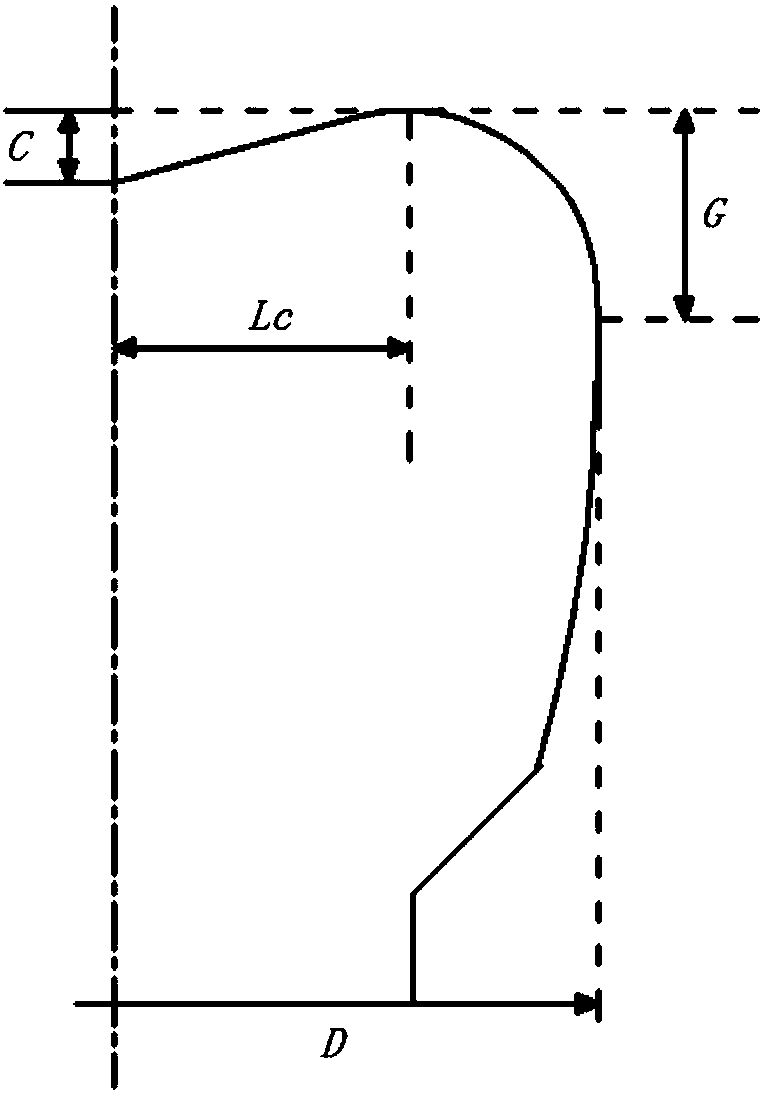

Directional CDE drill bit suitable for hard rock stratum

A drill bit and formation technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., can solve the problems of difficulty in deflection, poor stability of drill bit, and reduced rock breaking efficiency, so as to achieve good rock breaking ability in hard formation, reduce drilling cost, The effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0029] The inventor noticed during the invention process that the PDC drill bit uses polycrystalline diamond composite sheets to cut rocks. When drilling into a stratum with dense rock cementation and poor drillability, the polycrystalline diamond composite sheets cannot eat into the rock, and the rock breaking method is changed from cutting. For grinding, the efficiency of rock breaking is reduced, and the life of the drill bit is shortened due to increased w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com