Current sensor easy to install and with magneto-electric composite material

A magnetoelectric composite material and current sensor technology, applied in the direction of measuring current/voltage, instruments, measuring devices, etc., can solve problems such as difficulty in ensuring the complete closure of the magnetic gathering ring, limiting the scope of application, etc., to achieve stable and reliable measurement results and wide application range Wide, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

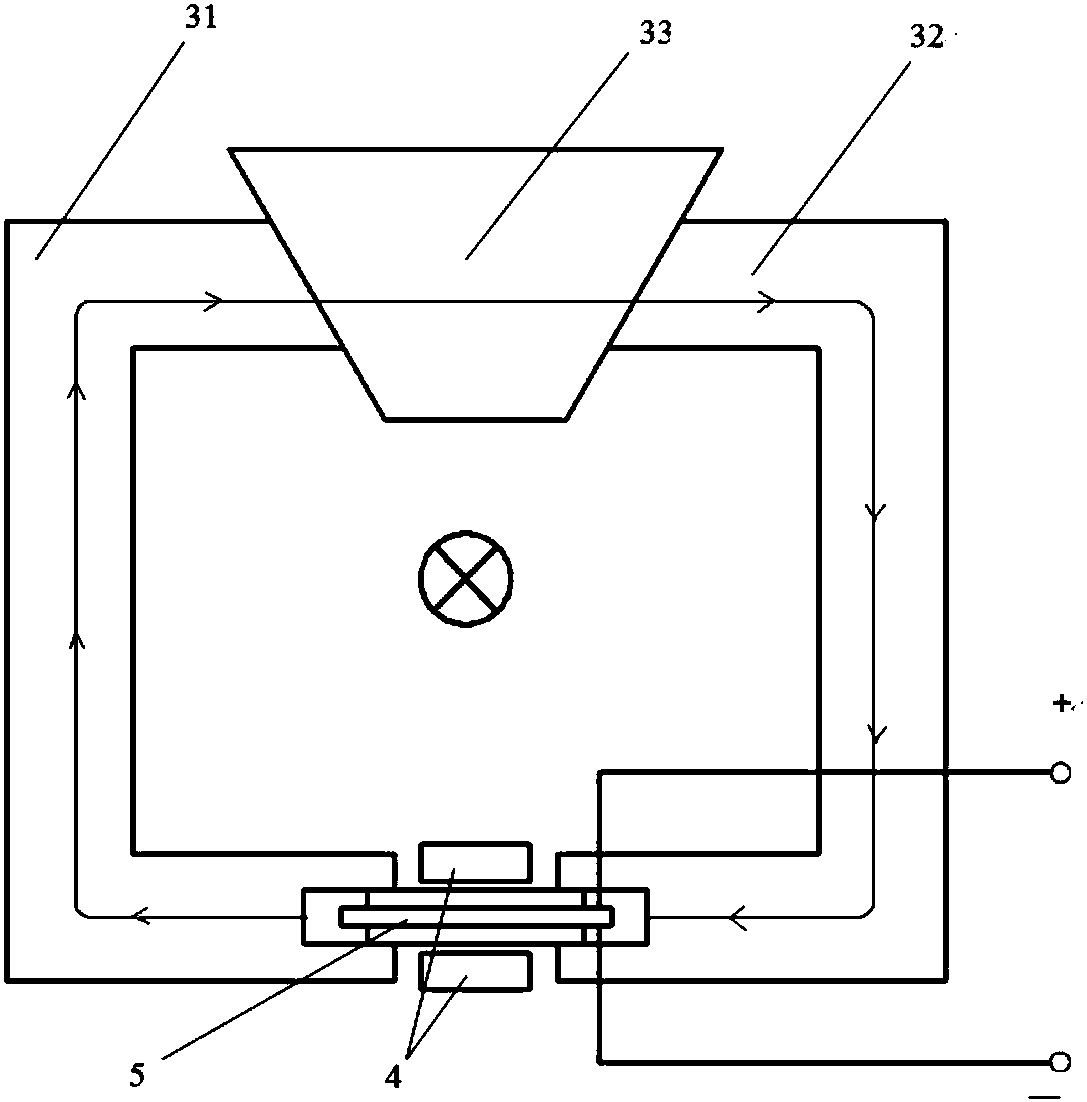

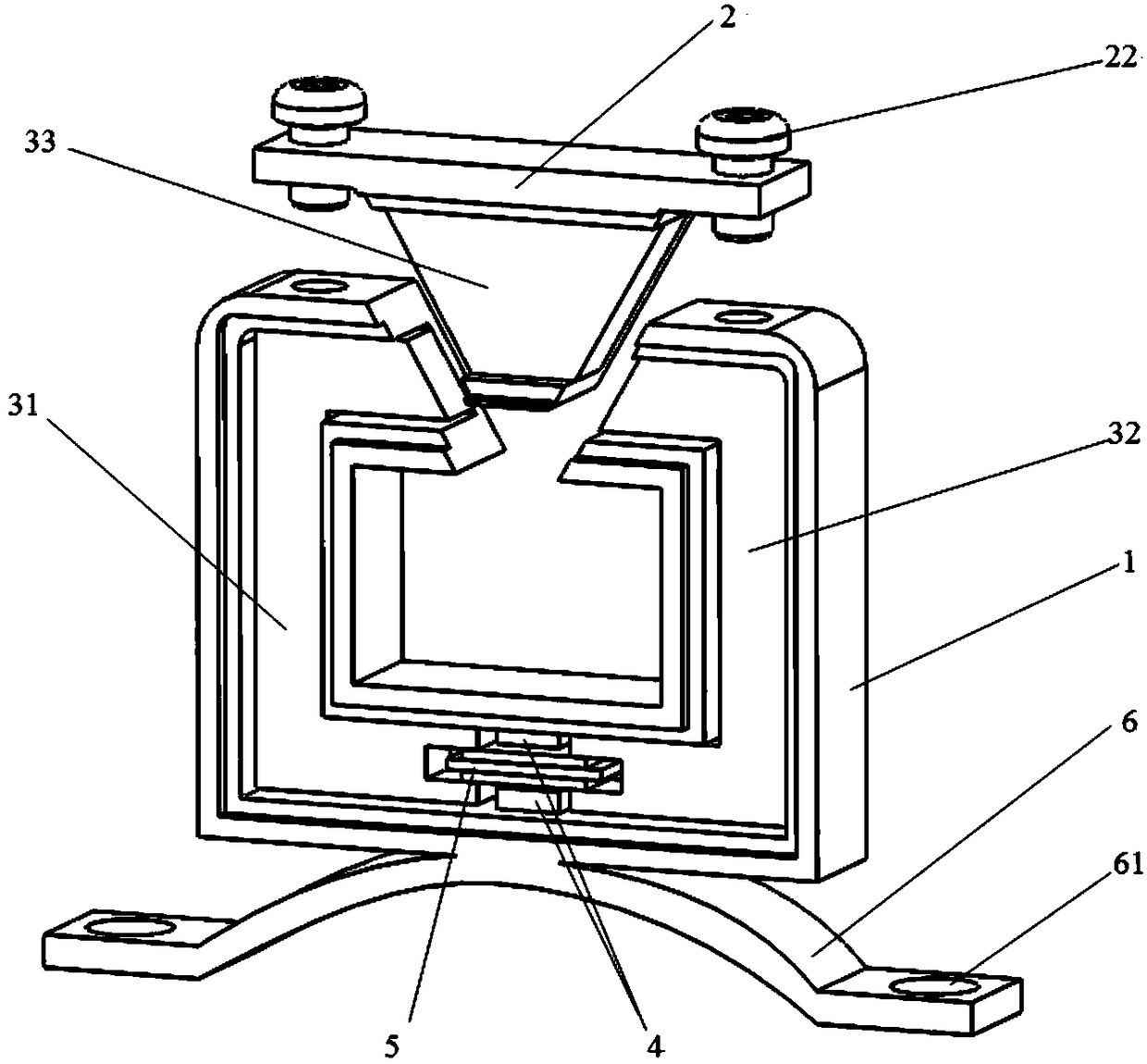

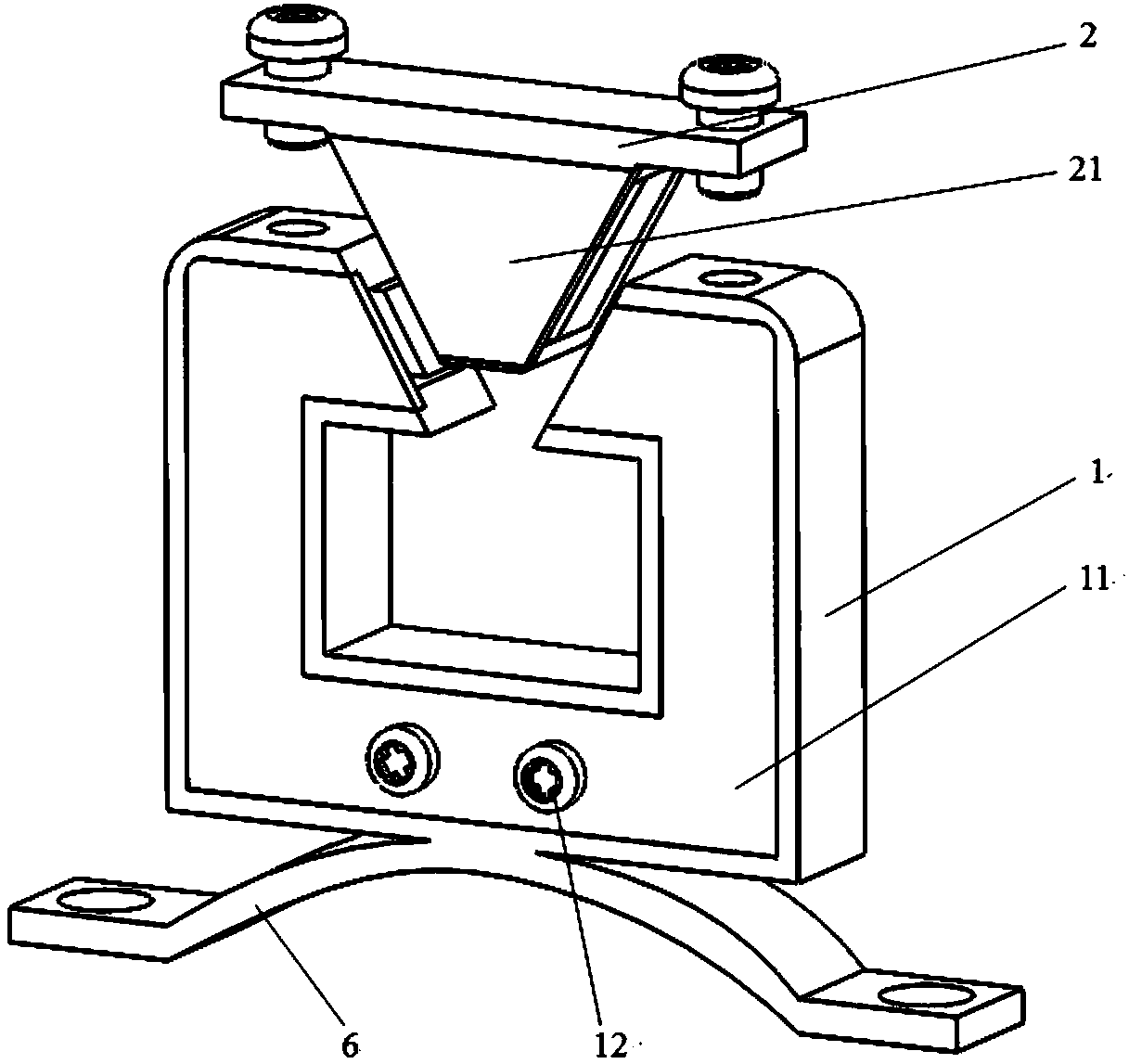

[0031] figure 1 It is a schematic diagram of the principle of the sensor. The current-carrying wire passes through the magnetic ring. According to the magnetic effect of the current, a circular magnetic field is generated around the wire. The magnetic ring is composed of a high magnetic permeability core 1 and a high magnetic permeability core 2 32. Three high-permeability magnetic cores 33 are formed. The ends of the high-permeability magnetic core one 31 and the high-permeability magnetic core two 32 are matched with grooves. The sensitive element 5 applies the annular magnetic field, the magnetostrictive material layer in the sensitive element 5 generates strain under the action of the magnetic field, and the mechanical motion is transmitted to the piezoelectric ceramic material layer through the bonding layer, and the piezoelectric ceramic material layer feels the strain And output a proportional voltage signal.

[0032] In this embodiment, the sensitive unit 5 is bonded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com